Gold needle mushroom cutting machine

A cutting machine and enoki mushroom technology, applied in metal processing and other directions, can solve the problems of low work efficiency, difficult to clean, poor cutting quality, etc., and achieve the effect of saving time and cost, neat cutting parts, and high cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings.

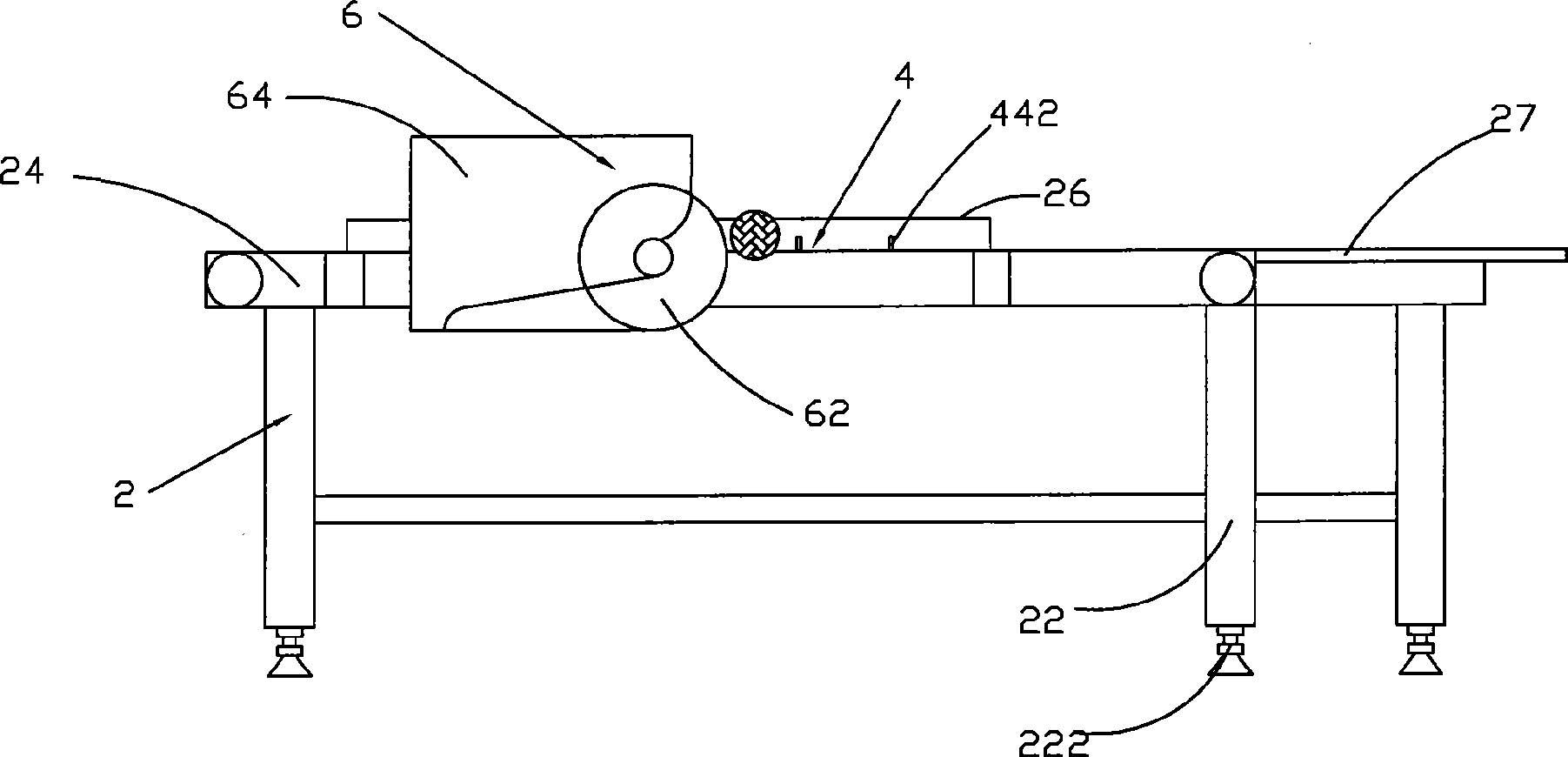

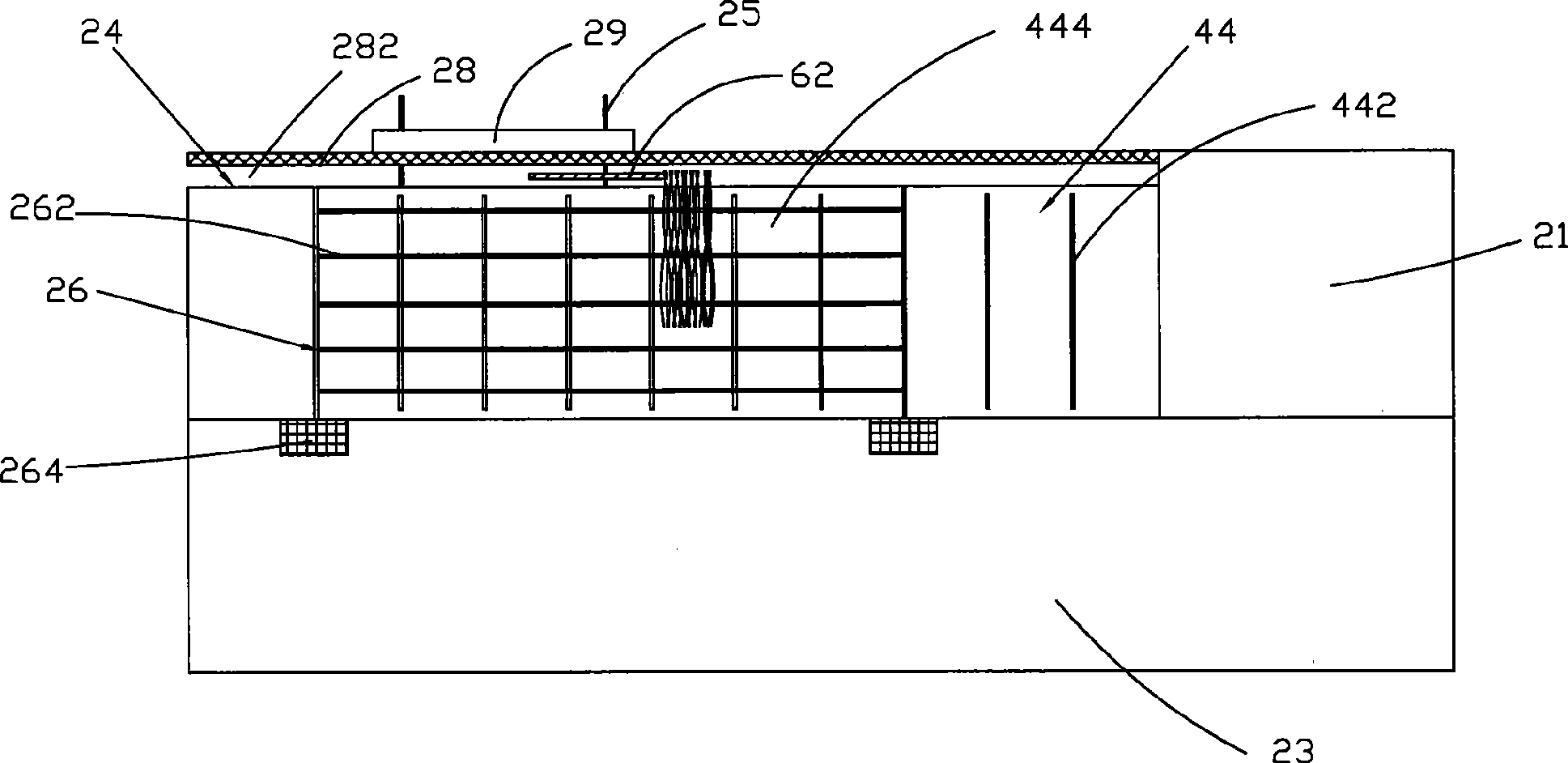

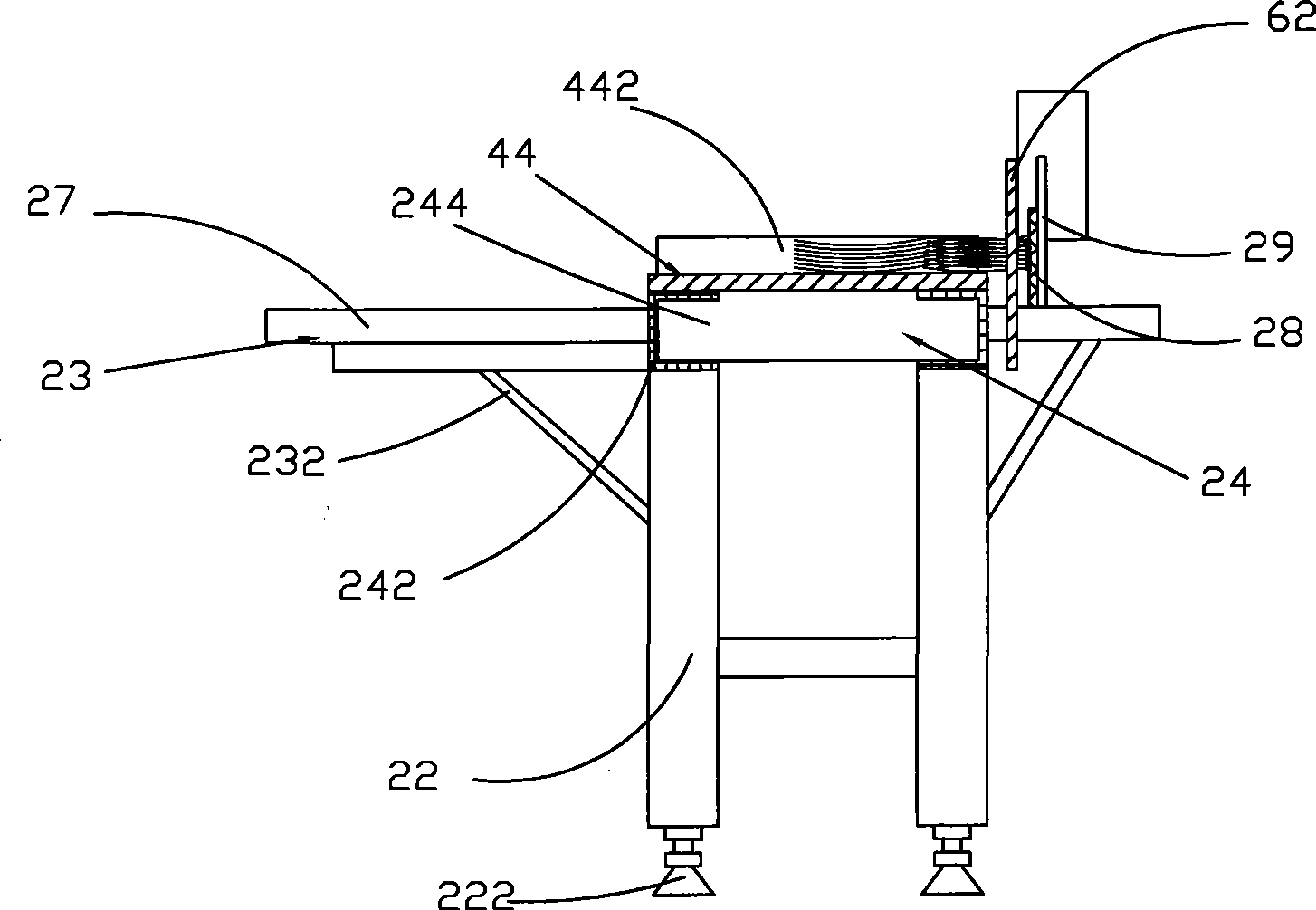

[0013] refer to Figure 1-3 , Flammulina velutipes cutting machine of the present invention comprises frame 2, conveying device 4 and cutting device 6.

[0014] Frame 2 comprises six tripods 22, the conveying platform 24 that places on the tripod 22, the fixed mount 26 that is located at the top of the conveying platform 24 and the positioning baffle plate 28 and the knife rest 29 that are located at the conveying platform 24 one side, feet Frame 22 is made of aluminum profile, and its lower end is provided with foot cup 222, can be used for adjusting smoothness.

[0015] The transport platform 24 includes a guide rail 242 and a supporting plate 244 placed in the guide rail 242. The guide rail 242 is two U-shaped frames arranged symmetrically and made of bent stainless steel.

[0016] Fixed frame 26 comprises several fixed baffles 262, and several fixed baffles 262...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com