PP sheet cutting equipment and method thereof

A technology of cutting equipment and cutting method, applied in welding equipment, laser welding equipment, metal processing equipment and other directions, can solve the problems of increasing the edge sealing process, increasing the edge sealing equipment for the edge sealing process, and increasing the production cost, so as to reduce the production cost. , to achieve automatic cutting, to avoid the effect of de-powder and de-silk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

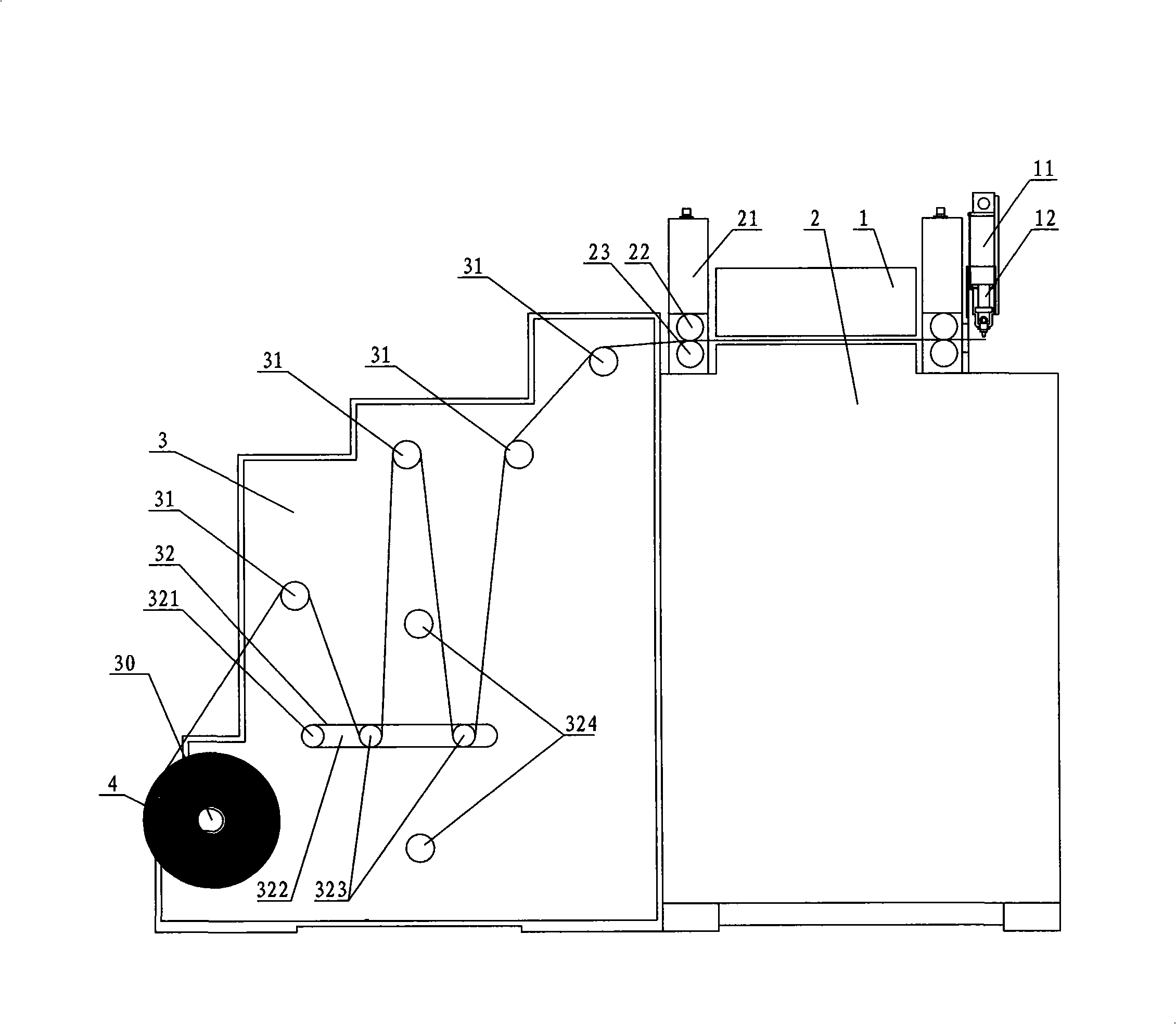

[0031] Such as image 3 As shown, the PP sheet cutting equipment of the present invention includes a main frame 2 , a worktable 1 arranged on the main frame 2 , and a feeding mechanism 3 arranged upstream of the worktable 1 . Workbench 1, main frame 2, and feeding mechanism 3 are connected to form an integrated structure. In addition, the cutting equipment further includes a human-computer interaction interface control system, so as to control and coordinate the actions of various components according to the parameters set by the user, so as to realize the automatic cutting of PP sheets.

[0032] The PP sheet transmission mechanism is housed on the mainframe 2. In this embodiment, the PP sheet transmission mechanism is a roller transmission mechanism arranged on at least one side of the workbench 1, and the roller transmission mechanism includes: a driving pressing wheel 23, a driven pressing wheel 22, and a driving pressing wheel for adjusting 23 and the pressure regulating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com