Cap arranging machine

A technology of cap unscrambling machine and main engine, which is applied in the field of cap unscrambling machines, can solve the problems of bottle cap damage, low production efficiency, powder and bottle cap bumping, etc., and achieve the goals of protecting safety, improving production efficiency, reducing energy consumption and noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Embodiments embodying the features and advantages of the present invention will be described in detail in the following description. It should be understood that the invention can have various changes in different examples without departing from the scope of the invention, and that the descriptions and illustrations therein are illustrative in nature rather than limiting the invention.

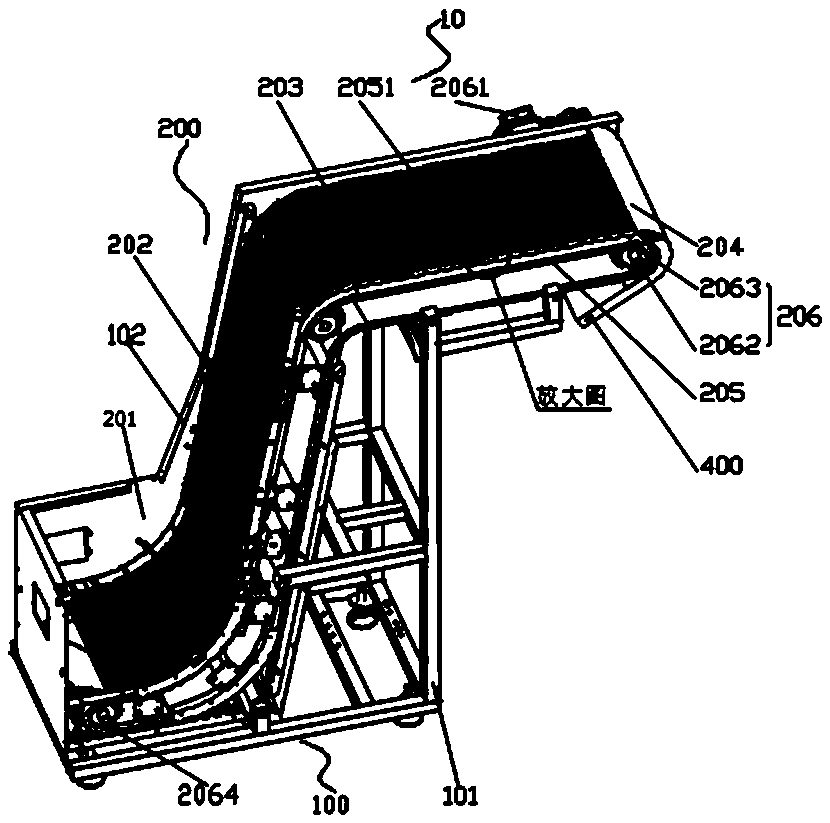

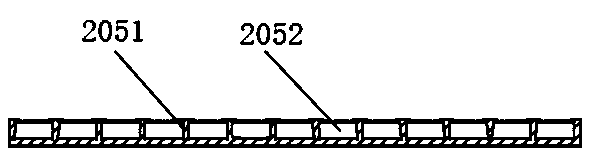

[0042] The embodiment of the present invention provides a cap unscrambling machine. figure 2 It is a schematic diagram of the overall structure of a cover unscrambling machine according to an embodiment of the present invention, as figure 2 As shown, the cap sorting machine 10 is suitable for sorting high caps. The cap sorting machine 10 includes: a main frame 100, which is in the shape of an inclined ladder; a conveyor belt mechanism 200, which is arranged on the main frame 100. The bottom of the frame 100 is provided with the lower horizontal section 201, the cover section 202, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com