Preparation method of battery pole piece and battery

A battery pole piece and electrode technology, which is applied in the direction of electrode manufacturing, battery electrodes, electrode heat treatment, etc., can solve the problems of low utilization rate of active materials, short circuit of batteries, inability to mix materials and binders uniformly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

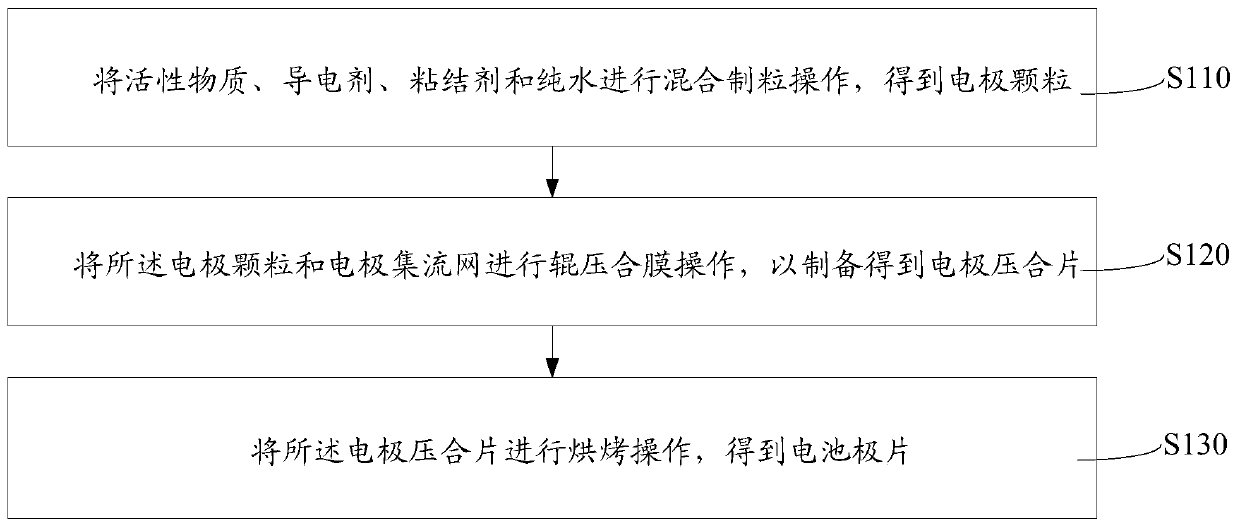

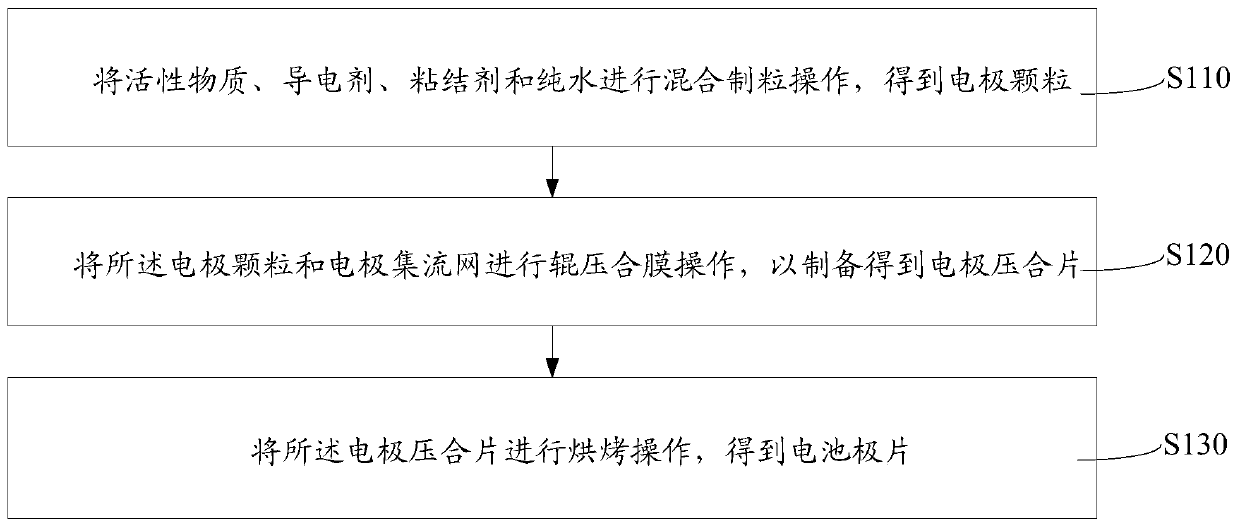

[0026] In order to better describe the method for preparing the above-mentioned battery pole piece, so as to better understand the concept of the above-mentioned method for preparing the battery pole piece. see figure 1 , in one embodiment, a method for preparing a battery pole piece, comprising the following steps:

[0027] S110, mixing and granulating the active material, conductive agent, binder and pure water to obtain electrode particles.

[0028] It can be understood that the performance of the electrode material has an important impact on the performance of the lithium-ion battery. The more uniform the components in the electrode material are dispersed, the better the processing performance of the electrode sheet, and the more uniform the impedance distribution of the electrode sheet. The greater the role of the active material during charging and discharging, the better the performance of the battery. In order to improve the performance of the electrode material, the...

Embodiment 1

[0043] Add 90kg of manganese dioxide, 2kg of conductive carbon, 4kg of polytetrafluoroethylene and 8kg of pure water into the granulator at an online speed of 4m / s, and perform a 2min mixing and granulation operation to obtain electrode particles with a particle size of 0.3mm ;

[0044] The electrode particles and the positive electrode aluminum foil current collecting net with a plurality of diamond-shaped holes with a rhombus length of 1 mm are subjected to roll lamination operation, and the distance between the two rolls is controlled to be 0.4 mm, and the linear pressure is 700 N / cm to prepare Electrode pressing sheet;

[0045] Under the temperature condition of 200° C., the electrode laminated sheet was baked, followed by sizing operations 4 times, and finally cut and stripped to obtain the battery electrode sheet of Example 1.

Embodiment 2

[0047] Add 91kg of manganese dioxide, 3kg of carbon nanotubes, 4kg of polytetrafluoroethylene and 10kg of pure water into the granulator at an online speed of 5m / s, and perform a 3min mixing and granulation operation to obtain an electrode with a particle size of 0.5mm particles;

[0048] The electrode particles and the positive electrode aluminum foil collector net with a plurality of diamond-shaped holes with a rhombus length of 1 mm are subjected to roll lamination operation, the distance between the two rolls is controlled to be 0.5 mm, and the linear pressure is 750 N / cm to prepare Electrode pressing sheet;

[0049] Under the temperature condition of 210° C., the electrode press-bonded sheet was baked, followed by sizing operations four times, and finally cut and stripped to obtain the battery electrode sheet of Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com