Cutting device utilizing waste conveying belt for manufacturing mining support stripe

A cutting device and conveyor belt technology, used in transportation and packaging, coiling strips, metal processing, etc., can solve the problems of belt cutting resistance and power consumption, lack of belt transverse cutting function, affecting cutting quality and efficiency, etc. , to achieve the effect of saving material expenses, compact structure and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments and illustrations.

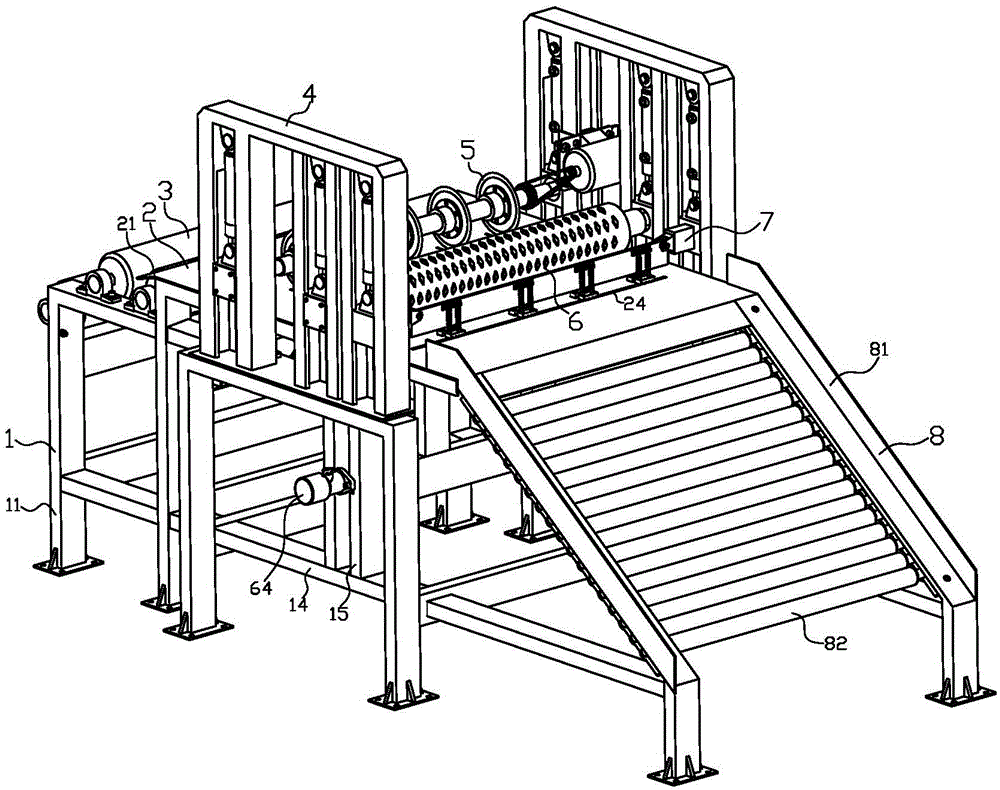

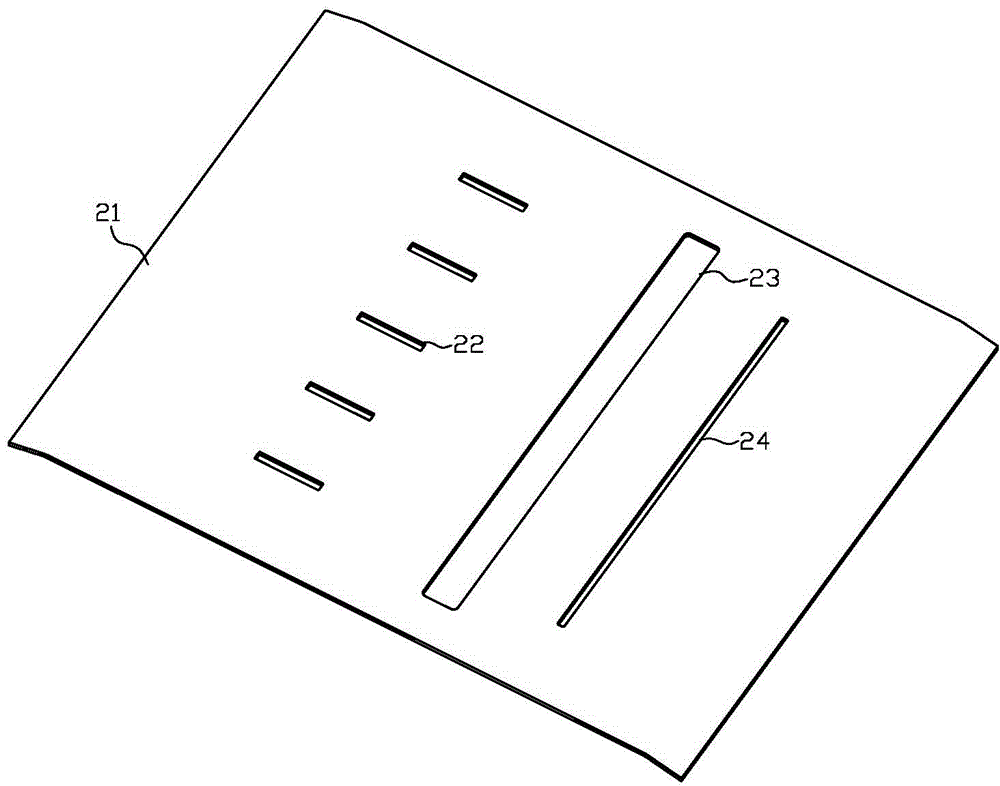

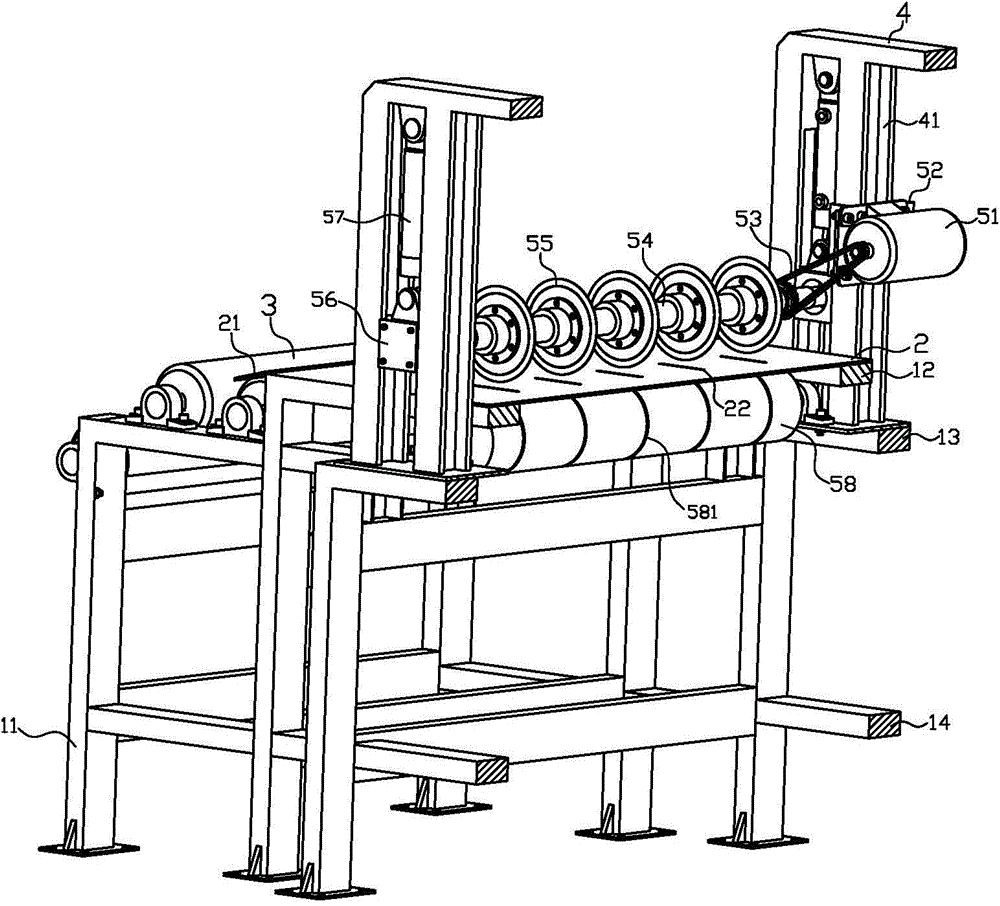

[0027] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 7 As shown, a cutting device for making mining support strips using waste conveyor belts, including a frame 1, a worktable 2, an introduction idler 3, a guide bracket 4, a longitudinal cutting device 5, a traction conveying device 6, a transverse Cutting device 7 and unloading device 8 . Wherein, the frame 1 includes supporting legs 11 , platform beams 12 , guide frame beams 13 , bottom beams 14 and connecting beams 15 . Described supporting leg 11 has ten in total, and its bottom is provided with anchor bolt hole, and described platform support beam 12 is positioned at the top of frame 1, is used for supporting, installing work platform 2, and platf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com