Cutting head for high-speed low-layer cutting lathe

A cutting and low-level technology, applied in the field of fabric automatic cutting equipment, can solve the problems of cumbersome tool change and adjustment of knife setting work, cutting waste fabrics, single function of cutting head, etc., to ensure cutting accuracy and smoothness, and reduce usage Cost, the effect of improving cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

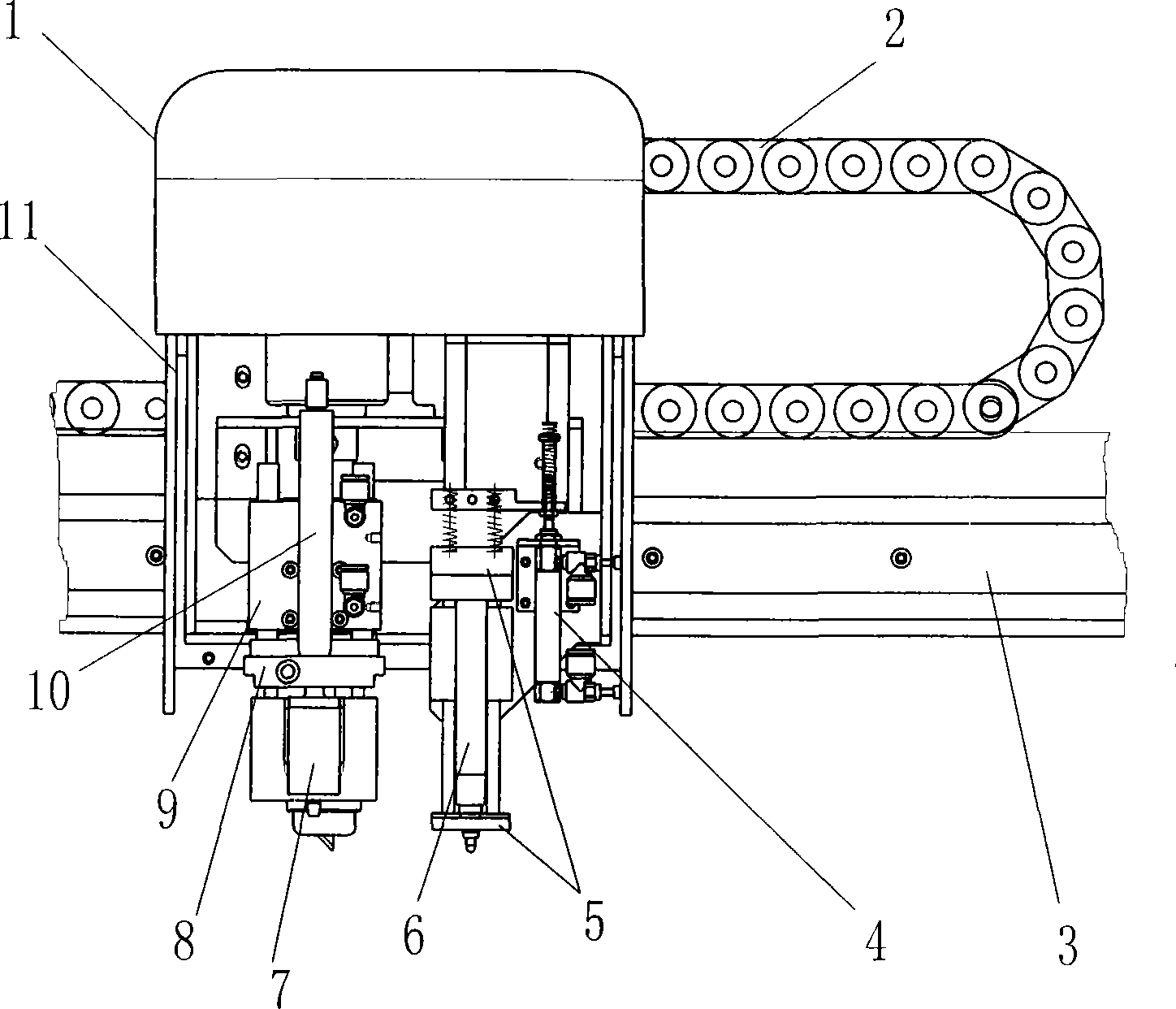

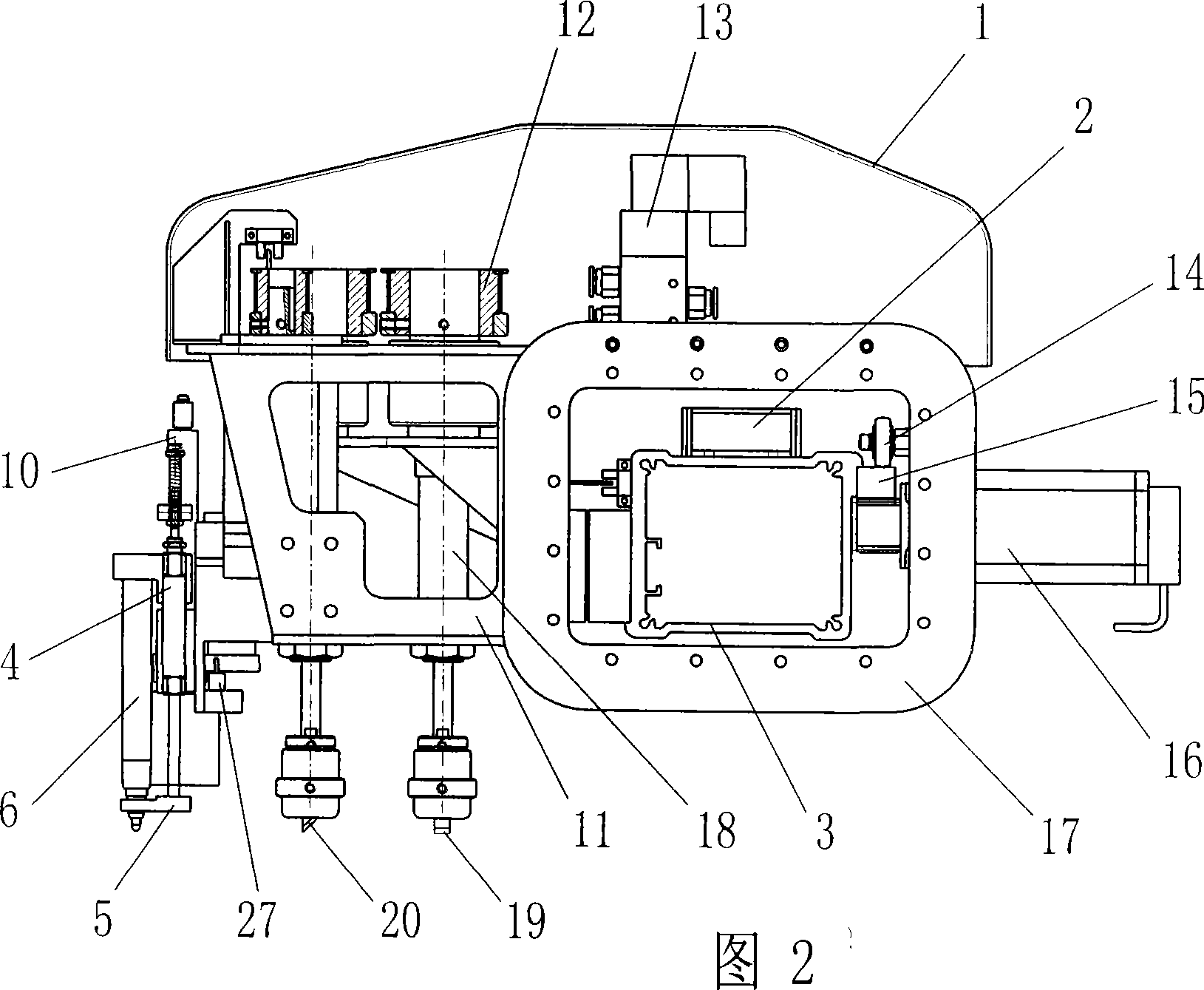

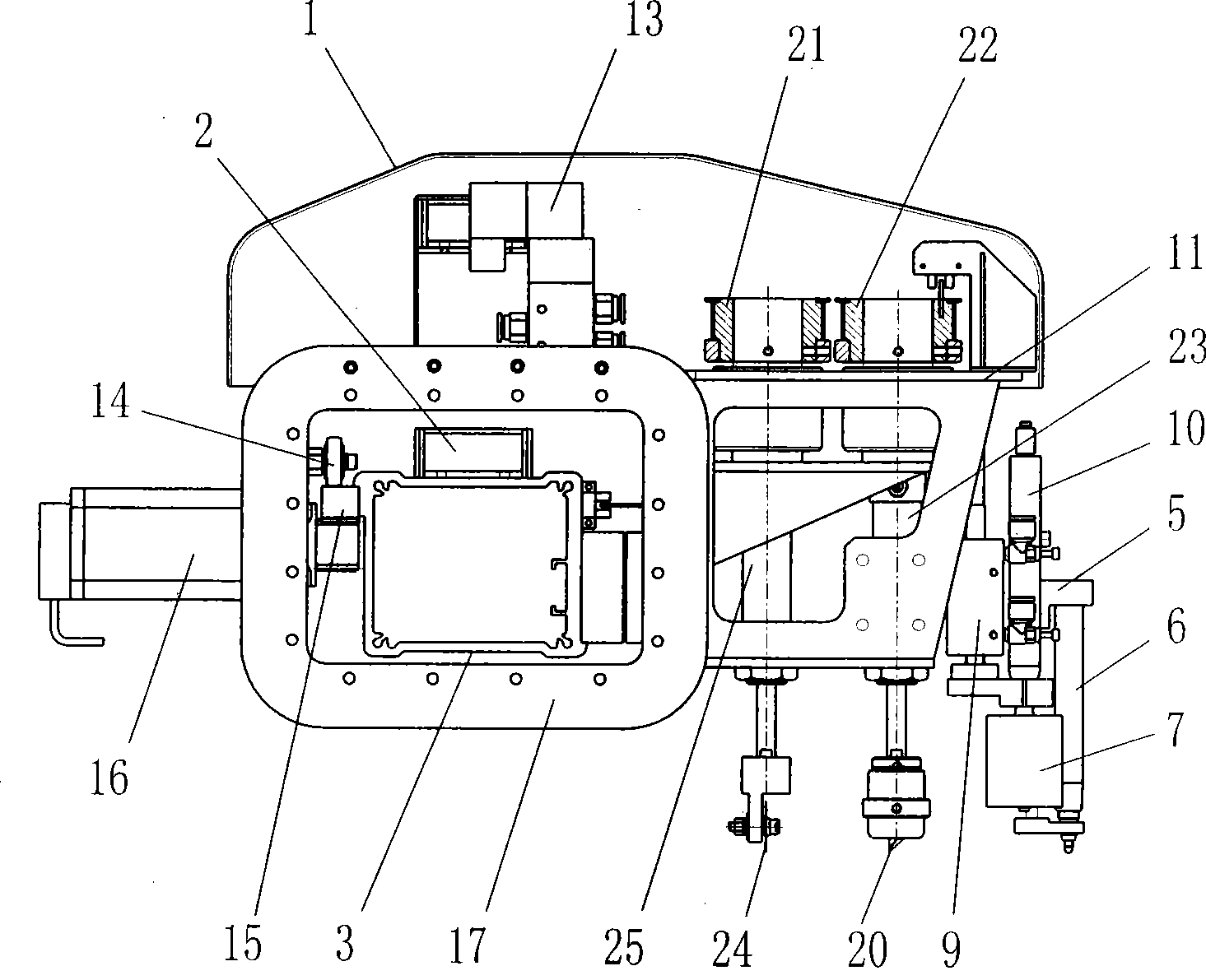

[0023] Such as Figure 1-Figure 4 A cutting head for a high-speed low-layer cutting machine shown, including a cutting head frame 11, on which a pen 6, a flat knife 19, a pointed knife 20, a round knife 24 and a punching drill are arranged. 7. The pen 6 is located on the pen holder 5, the pen holder 5 is connected to the vertical moving end of the pen-down cylinder 4, and the fixed end of the pen-down cylinder 4 is connected to the cutting head frame 11; the flat knife 19 is located on the flat The lower end of the piston rod of the knife cylinder 18, the flat knife cylinder 18 is vertically fixed on the cutting head frame 11, the piston rod upper end of the flat knife cylinder 18 is connected with the flat knife belt wheel which is arranged on the cutting head frame 11 in rotation 12 spline connection; described sharp knife 20 is located at the piston rod lower end of sharp knife cylinder 23, and described sharp knife cylinder 23 is vertically fixed on the cutting head frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com