Method for manufacturing main body structure of wind turbine tower

A technology of the main structure and manufacturing method, which is applied to wind power generation, towers, building types, etc., can solve the problems such as failure to improve the cutting efficiency of fan-shaped steel plate grooves, flatness, parallelism easily out of tolerance, and different fan-shaped steel plates. Achieve the effects of enhanced arc penetration ability, reduced positioning time, and reduced planing amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

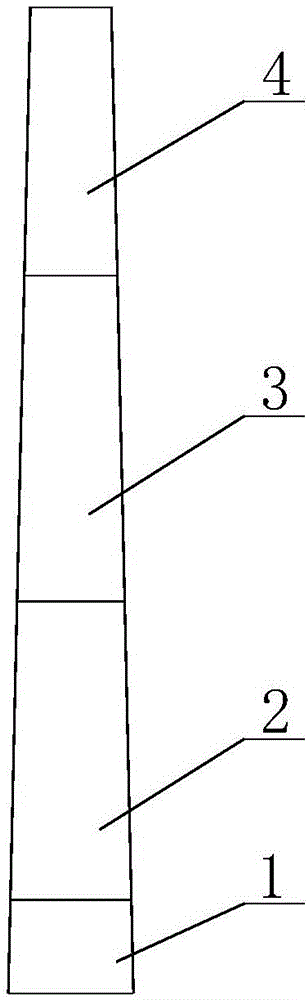

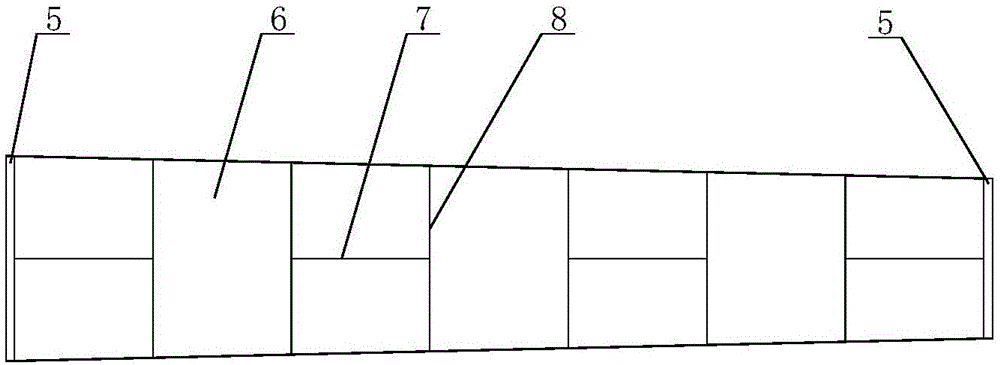

[0061] A method for manufacturing a main structure of a wind power generation tower, such as figure 1 As shown, the main structure of the wind power tower is composed of a base ring 1, a lower tower 2, a middle tower 3 and an upper tower 4 which are sequentially connected from bottom to top. The base ring 1 and each tower 2, 3, 4 are produced separately and connected by flange 5; the specific production process is as follows:

[0062] 1) Blanking and cutting:

[0063] The bodies of the base ring 1 and the tower tubes 2, 3, and 4 of each section are all conical cylinders, and the cylinders are composed of one or more cylinder sections 6, and each cylinder section 6 is made of steel plates with different thicknesses;

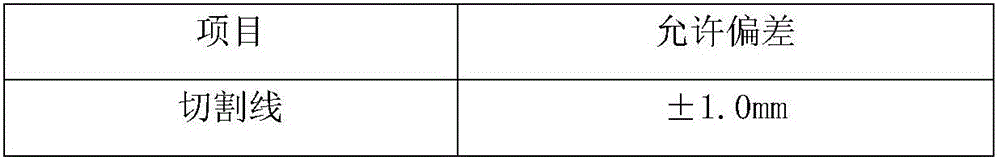

[0064] Firstly, each cylinder section 6 is lofted and expanded according to the construction drawing, and the expanded cylinder sect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com