Cutting device of adjustable heading type vegetable harvesting machine

A cutting device and harvester technology, applied in harvesters, agricultural machinery and implements, applications, etc., can solve the problems of low cutting efficiency, large cutting reaction force, easy cutting damage, etc. for balled vegetables, so as to improve cutting efficiency and Cutting quality, efficient cutting, effect of reducing cutting reaction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

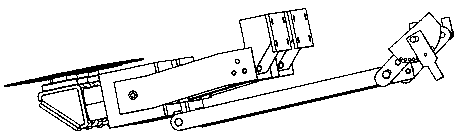

[0027] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes. This scheme is mainly applicable to the cutting of ball vegetables. During the cutting process, the cutting angle, cutter speed, and cutter type can be adjusted or replaced according to the actual situation, which effectively reduces the cutting force and cutting energy during the cutting process. It reduces the cutting damage rate and improves the cutting efficiency.

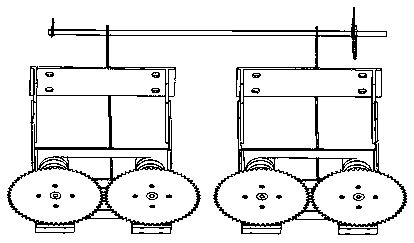

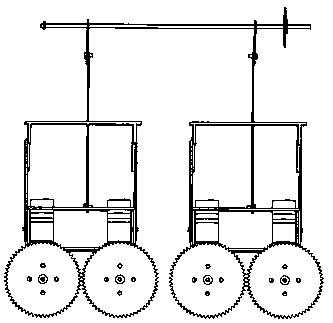

[0028] Such as Figure 1~4 The cutting device of an adjustable knot vegetable harvester includes a fixing mechanism, a transmission mechanism installed on the fixing mechanism, and a connecting mechanism hinged to the fixing mechanism through a horizontal hinge shaft. The underframe of the harvester lifting conveying device is fixedly connected, and the adjusting mechanism that drives the fixing mechanism to rotate around the transverse hinge axis is also ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com