Drill bit for processing thin flexible material

A flexible material and thin technology, which is applied in metal processing, metal processing equipment, drilling repair, etc., can solve the problems of thin flexible material drilling, unfavorable precise processing, and lack of precision, so as to achieve low cost and improve processing accuracy , making convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

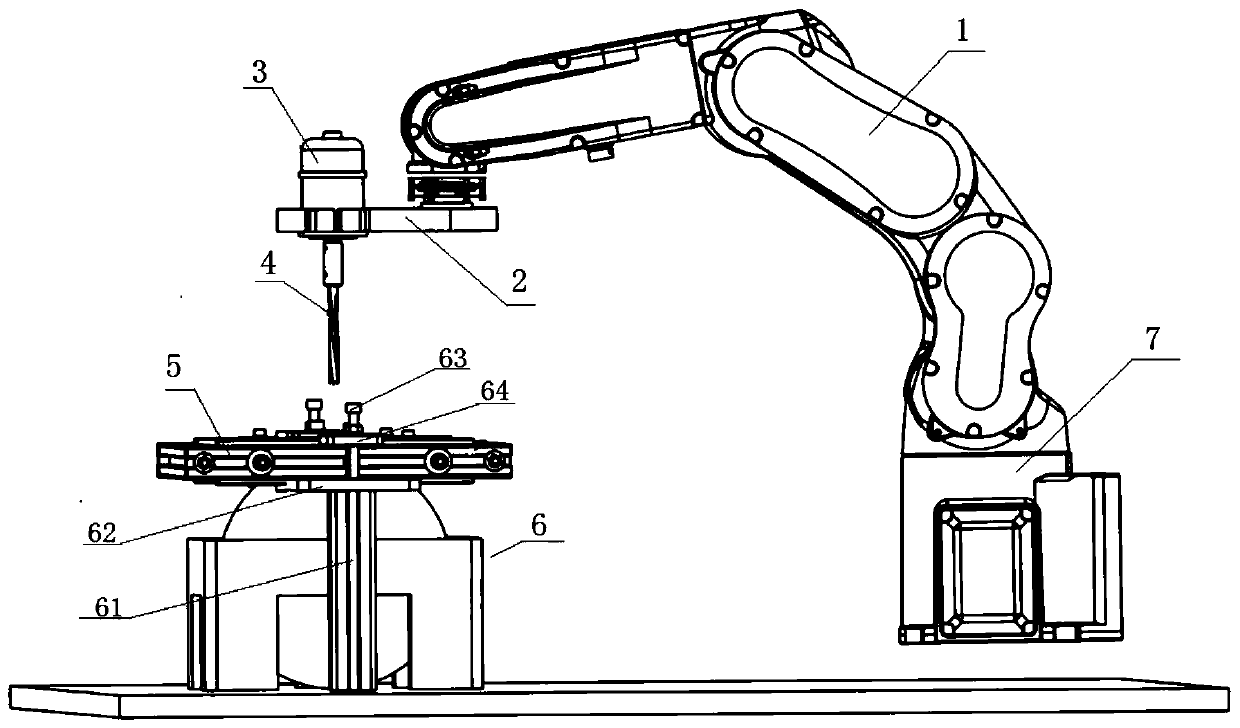

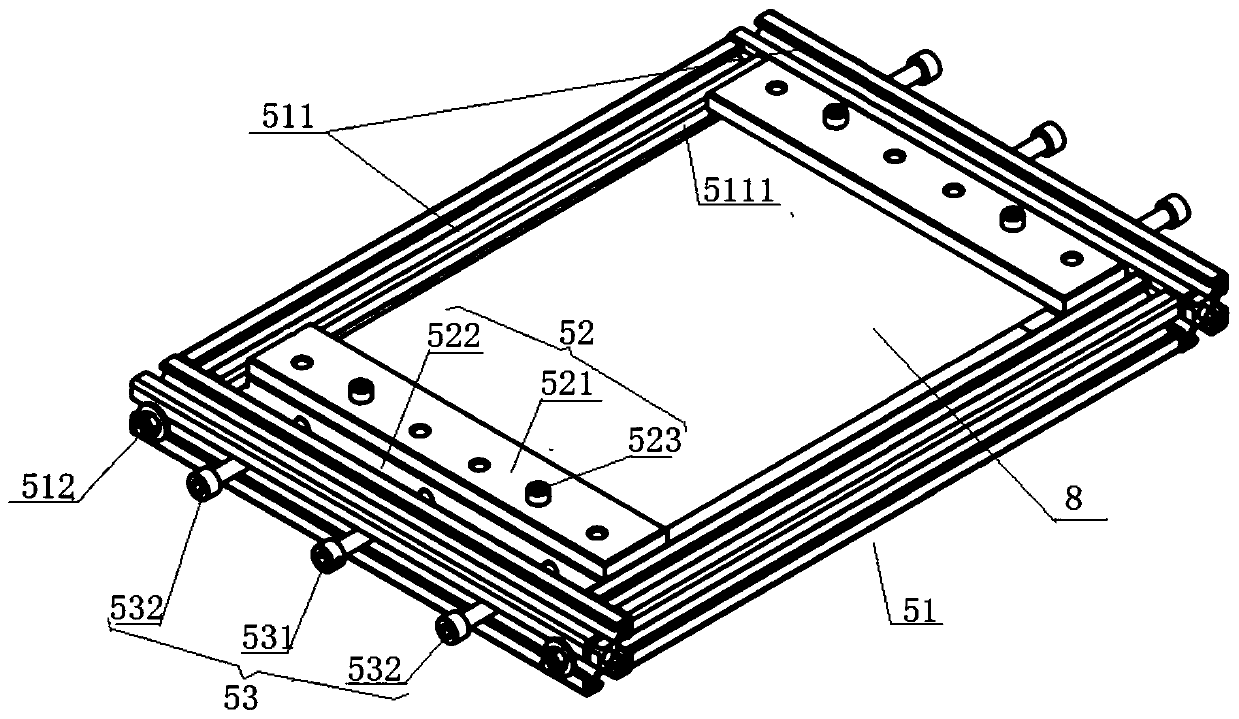

[0021] The drill bit for processing thin flexible materials in this embodiment can be applied to the mechanical arm system for processing thin flexible materials, such as figure 1 Shown, this mechanical arm system comprises mechanical arm 1, processing device, clamp 2, tensioning frame 5 and support 6, wherein: mechanical arm 1 is arranged on the base 7; It is composed of a drilling motor 3 for driving the three-piece drill 4 to rotate; the clamp 2 is arranged at the end of the mechanical arm 1, and is used for connecting the processing device with the mechanical arm 1; the tensioning frame 5 is arranged within the range of motion of the processing device, For fixing and tensioning the thin flexible material 8; the bracket 6 is detachably connected to the tensioning frame 5 for supporting the tensioning frame 5.

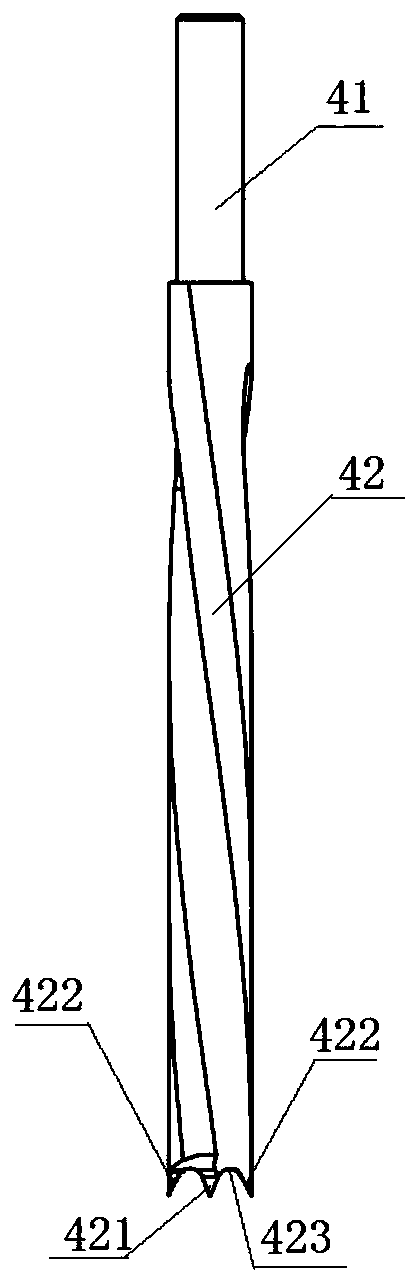

[0022] like figure 2 As shown, the drill bit (three-pointed drill 4) of the present invention includes a shank 41 and a working part 42 arranged in sequence. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com