Aviation aluminum alloy machining vibration cutting equipment and working method

A technology of cutting equipment and machining vibration, applied in metal processing equipment, metal processing mechanical parts, tool clips, etc., can solve the problems of poor generality, affecting equipment use efficiency, low equipment use efficiency, etc., and achieve the effect of convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

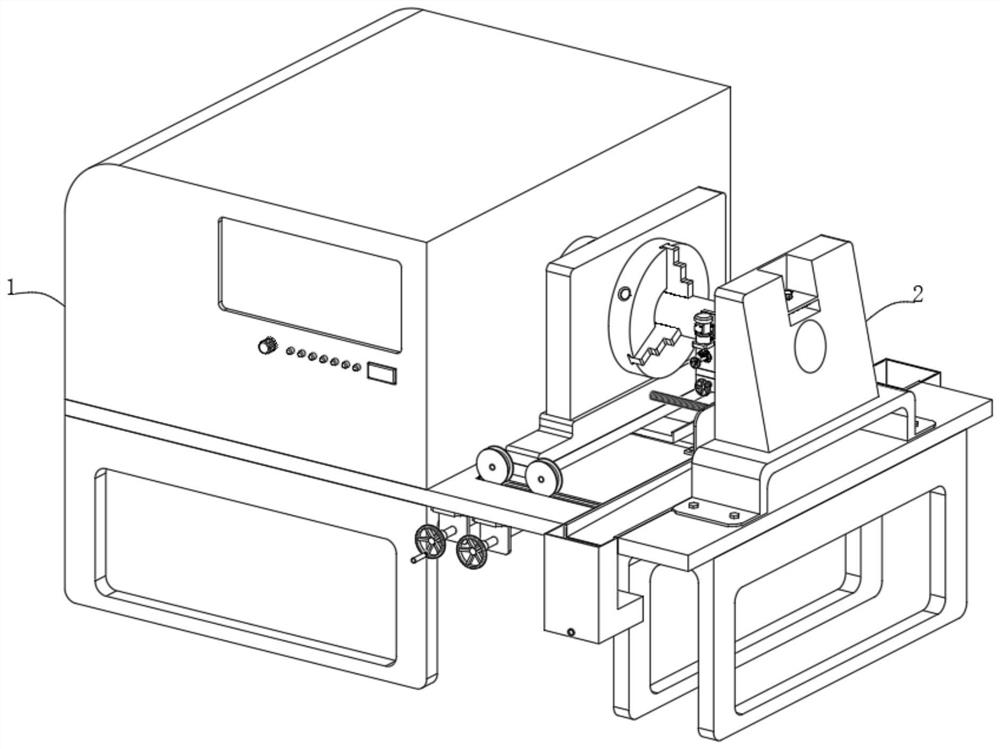

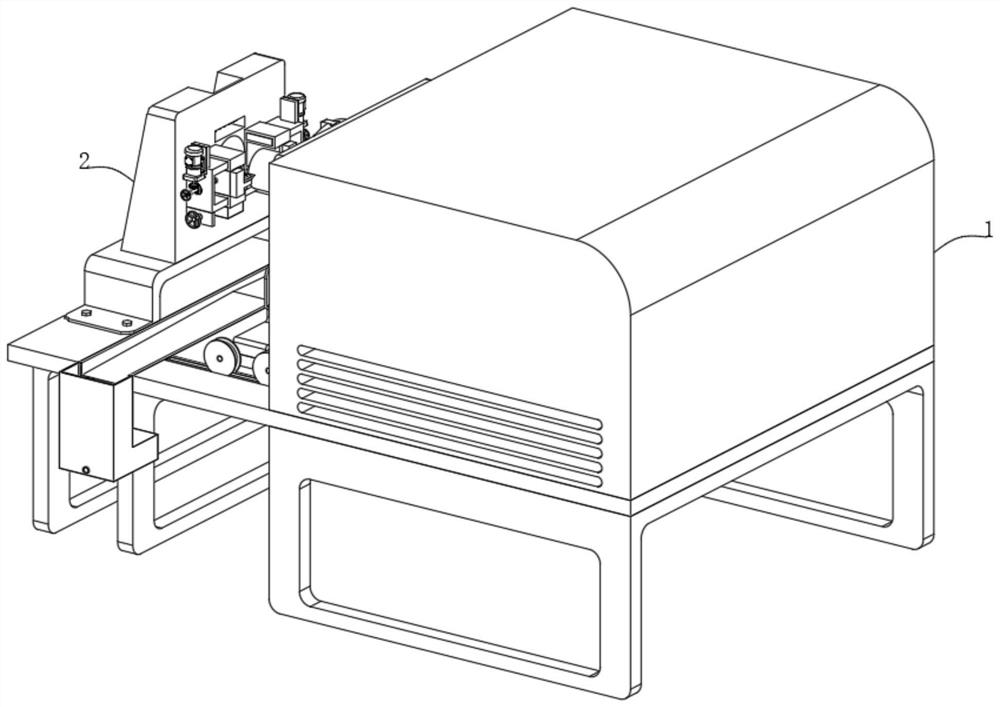

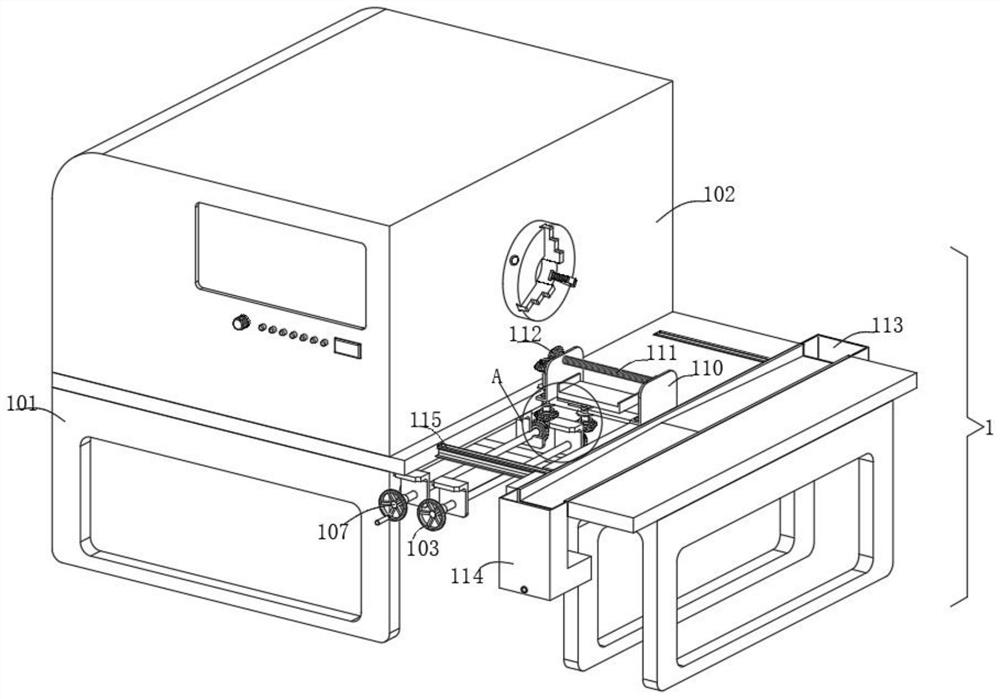

[0033] refer to Figure 1-Figure 7: A vibratory cutting equipment for machining aluminum alloys for aviation, comprising: a support mechanism 1, the support mechanism 1 includes a base 101, and the establishment of the base 101 provides an installation basis for other functional parts of the equipment, and at the same time enables the equipment to perform its due functions stably Realization, the top of the base 101 is fixedly connected with the cutting equipment body 102, and the establishment of the equipment body 102 enables the equipment to normally perform its due functions. The top of the base 101 is fixedly connected with two support plates 110, and the establishment of the support plates 110 is convenient. For the installation and setting of other functional components of the equipment, a moving threaded rod 111 is rotationally connected between the opposite outer surfaces of the two support plates 110. The setting of the moving threaded rod 111 facilitates the effectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com