Cutting machine

A cutting machine and cutting technology, applied in the direction of sending objects, thin material processing, transportation and packaging, etc., can solve the problems of difficult control of manual cutting accuracy, inability to meet large-scale production, low efficiency, etc., to meet large-scale Effect of Scaling Requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

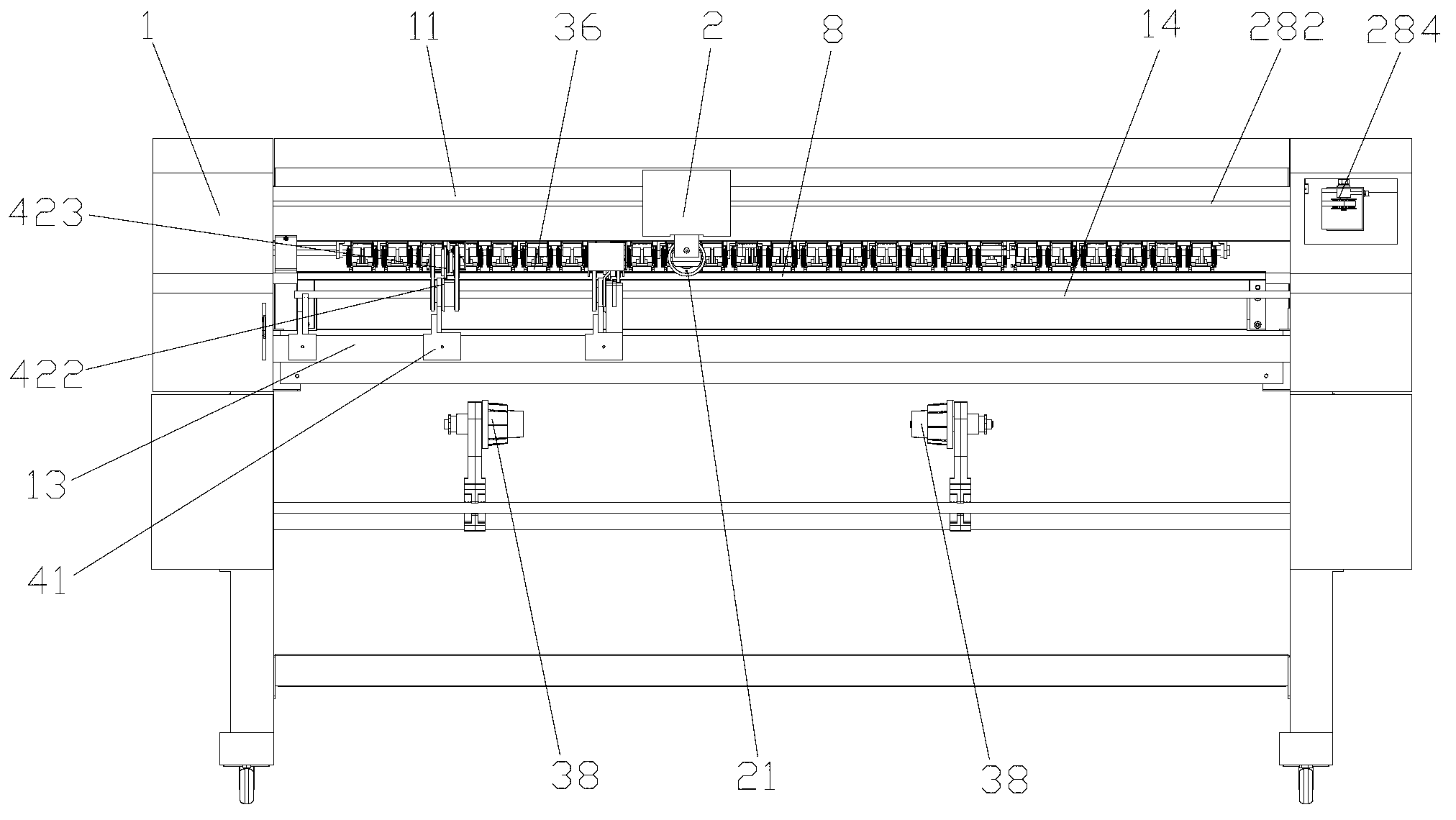

[0041] by figure 2 The state shown shall prevail. The horizontal direction in the present invention refers to the direction of left and right movement, the vertical direction refers to the direction of up and down movement, and the longitudinal direction refers to the direction perpendicular to the paper.

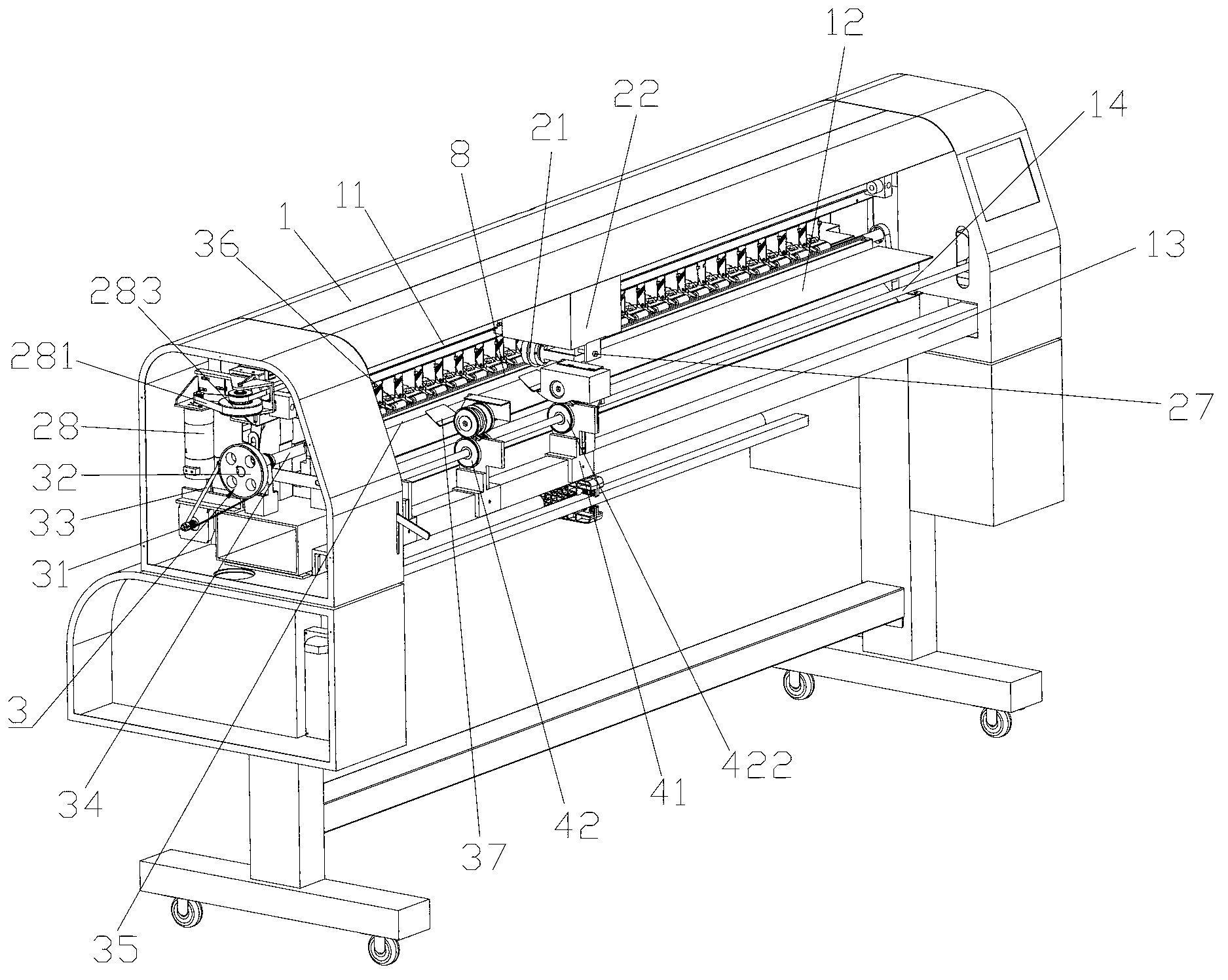

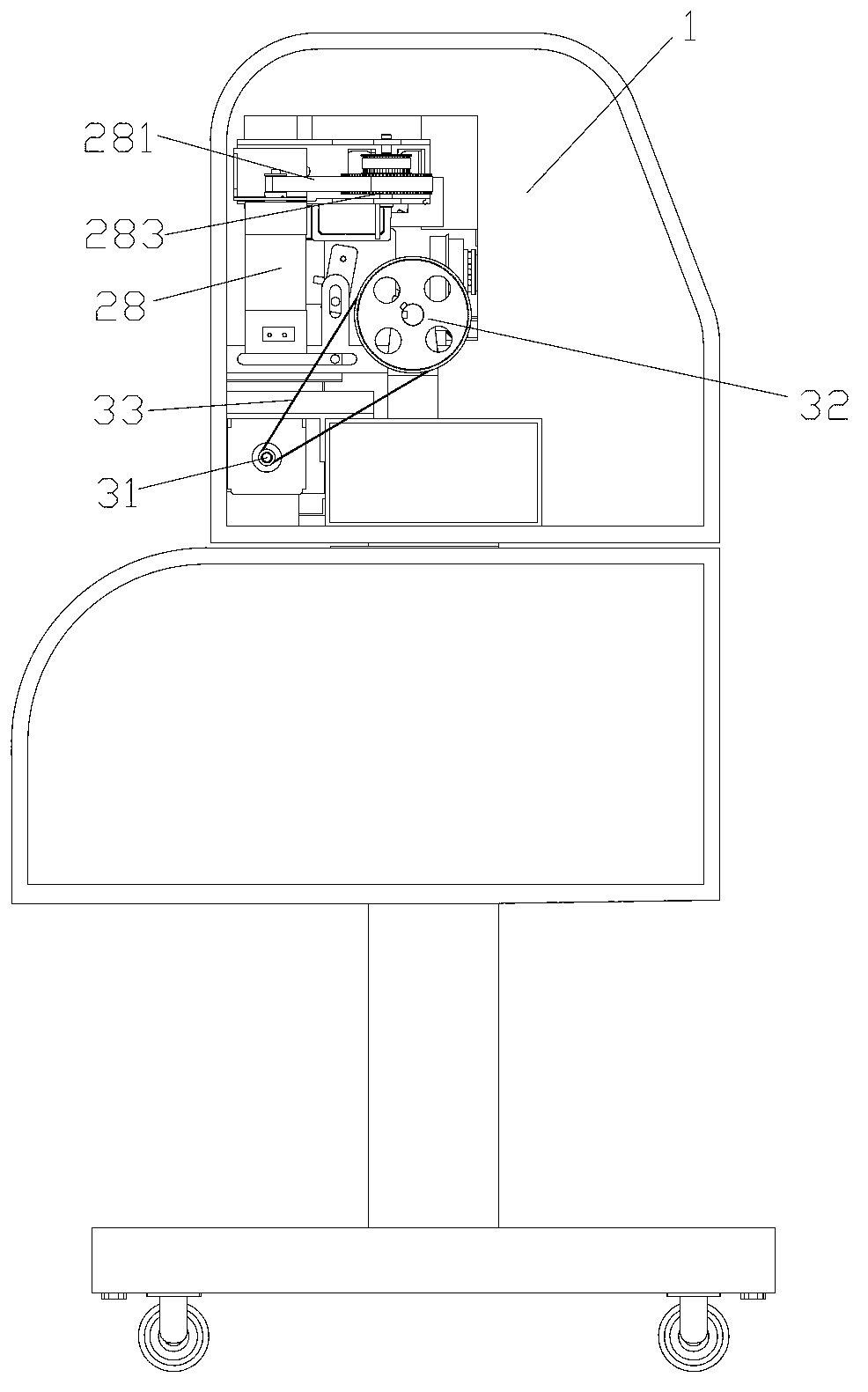

[0042] Such as Figure 1 to Figure 8 Shown: Cutter, used to cut printed media. The cutting machine comprises a frame 1, a first cutting device 2, two second cutting devices 4, a first drive device, a second drive device, a transport device 3 for conveying the medium 7, a support for the medium 7 A platen 8 and a camera 6 for detecting the position of the medium 7 . First cutting device 2, two second cutting devices 4, first drive device, second drive device, conveying device 3 for conveying medium 7, platen 8 for supporting medium 7 and for detecting medium The cameras 6 at the 7 positions are all arranged on the rack 1 .

[0043] Medium 7 is along with the figure 2 ...

Embodiment 2

[0058] Such as Figure 9 As shown, the difference between this embodiment and Embodiment 1 is that the number of second cutting devices is three. Three second cutting devices are distributed along the transverse direction of the frame 1 .

[0059] The cutting machine of the present invention replaces the manual cutting of the printed medium in the traditional inkjet printing field, realizes the automatic cutting of the medium, and can meet the large-scale cutting demand. In addition, the cutting machine of the present invention can not only cut the medium horizontally through the first cutting device, but also cut the medium vertically through the second cutting device, and can cut at least two parts of the medium in the same process. vertical sides.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com