Nursery stock grafting machine

A grafting machine and seedling technology, applied in horticulture, application, botany equipment and methods, etc., can solve the problems of high labor intensity, difficult to guarantee the survival rate of grafted seedlings, uneven seedling emergence, etc., to achieve high survival rate and improve labor production. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "inner" and "outer " refers to a direction towards or away from, respectively, the geometric center of the invention or a particular part thereof.

[0036] The purpose of the present invention is to realize the operation of automatic cutting and automatic grafting of fringe seedlings and rootstock seedlings, and the survival rate of grafting is higher than that of manual grafting. For this reason, the present invention preferably adopts the following technical solutions.

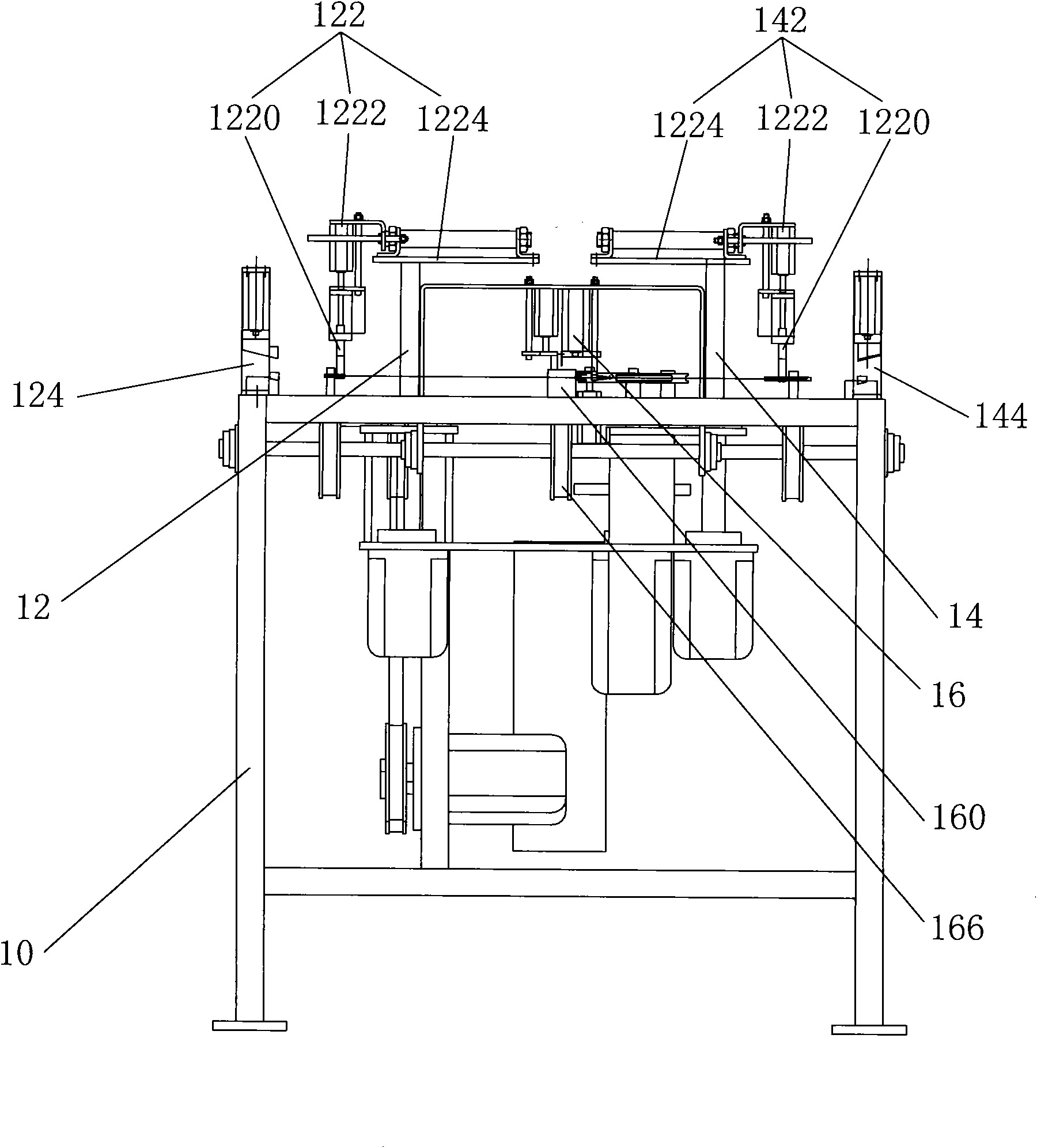

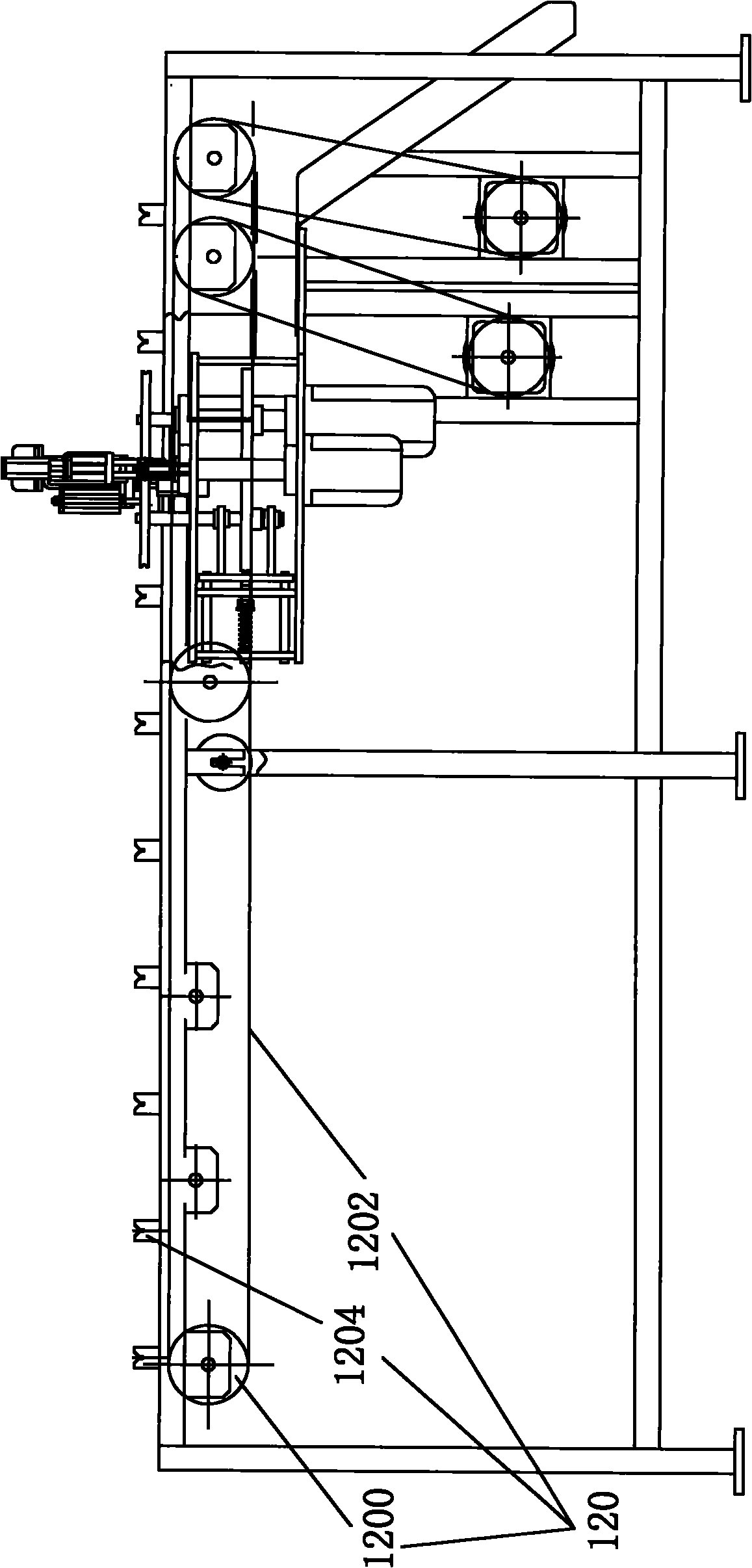

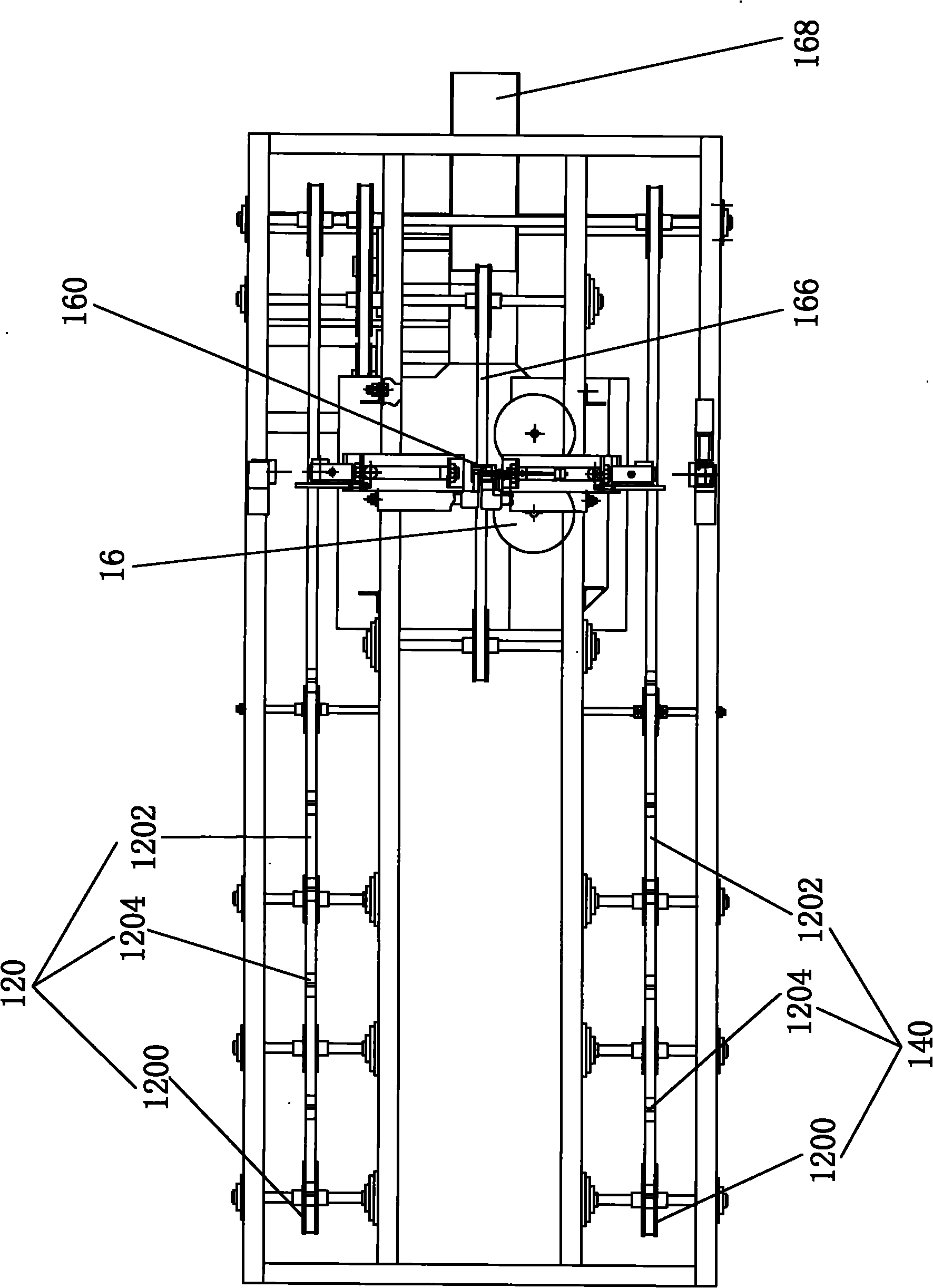

[0037] see figure 1 The seedling grafting machine of the present invention comprises a frame 10, a fringe wood processing mechanism 12 arranged on one side of the frame 10, a stock processing mechanism 14 arranged on the other side of the frame 10, a rootstock processing mechanism 14 arranged on the frame 10, Grafting mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com