Sheet material cutting method and automatic cutting machine

A cutting machine and sheet material technology, which is applied in the cutting of textile materials, textiles and papermaking, etc., can solve problems such as the decrease in the value of clothing materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0084]

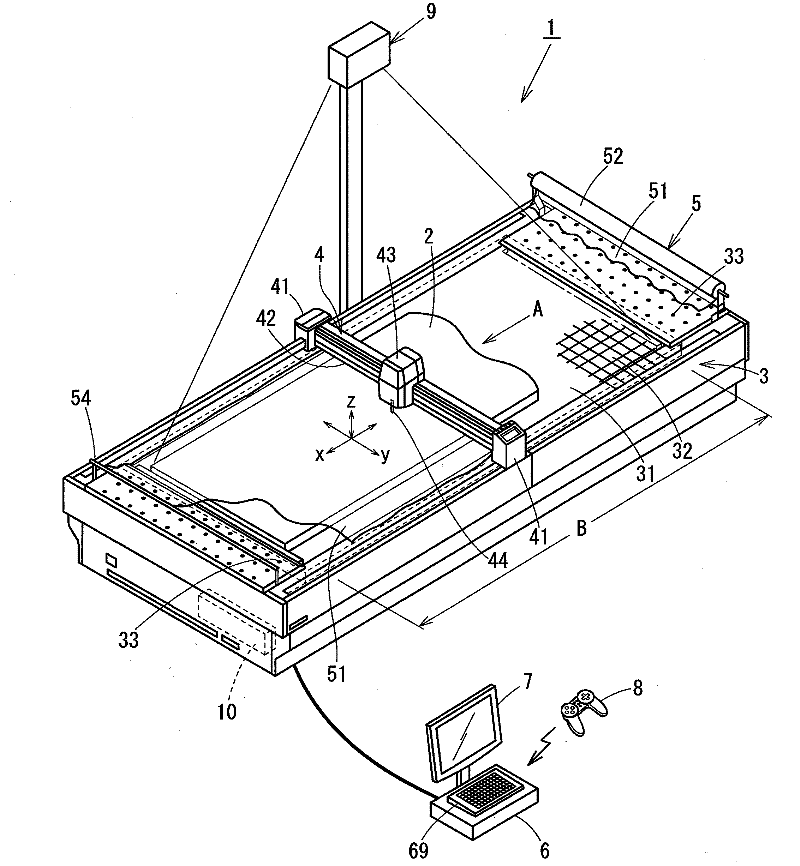

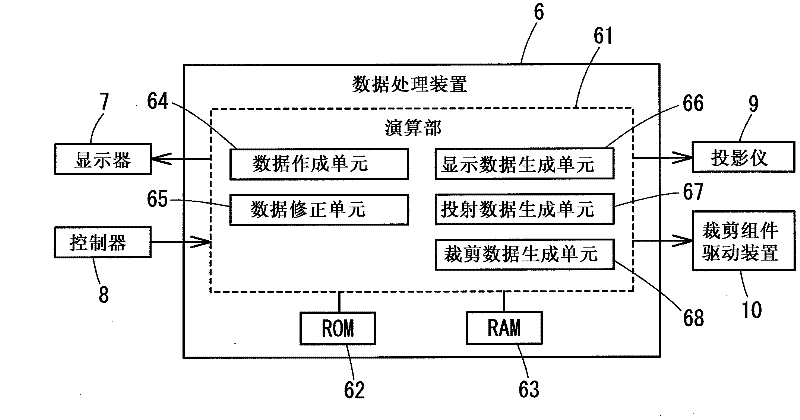

[0085] figure 1 The whole structure of the automatic cutting machine which implements the cutting method of this invention is shown. The automatic cutting machine 1 is composed of a cutting machine body 3 , a cutting assembly 4 , a cover sheet feeding device 5 , a data processing device 6 , a display 7 , a controller 8 , a projector 9 and a cutting assembly driving device 10 .

[0086] A workbench 31 is provided on the upper surface of the cutter body 3, and the workbench 31 is loaded with a patterned sheet 2 to be cut (partially cut out and shown in the figure). The table 31 is constituted by a conveyor belt, and the sheet 2 fed out from a laying device (not shown) is conveyed in the direction of arrow A by the conveyor belt and spreads on the table 31 . The surface of the table 31 is covered with a bristle brush 32 (only partially shown) to prevent the table 31 from being cut during cutting.

[0087] In the following description, such as figure 1 As shown, the ...

Embodiment approach 2

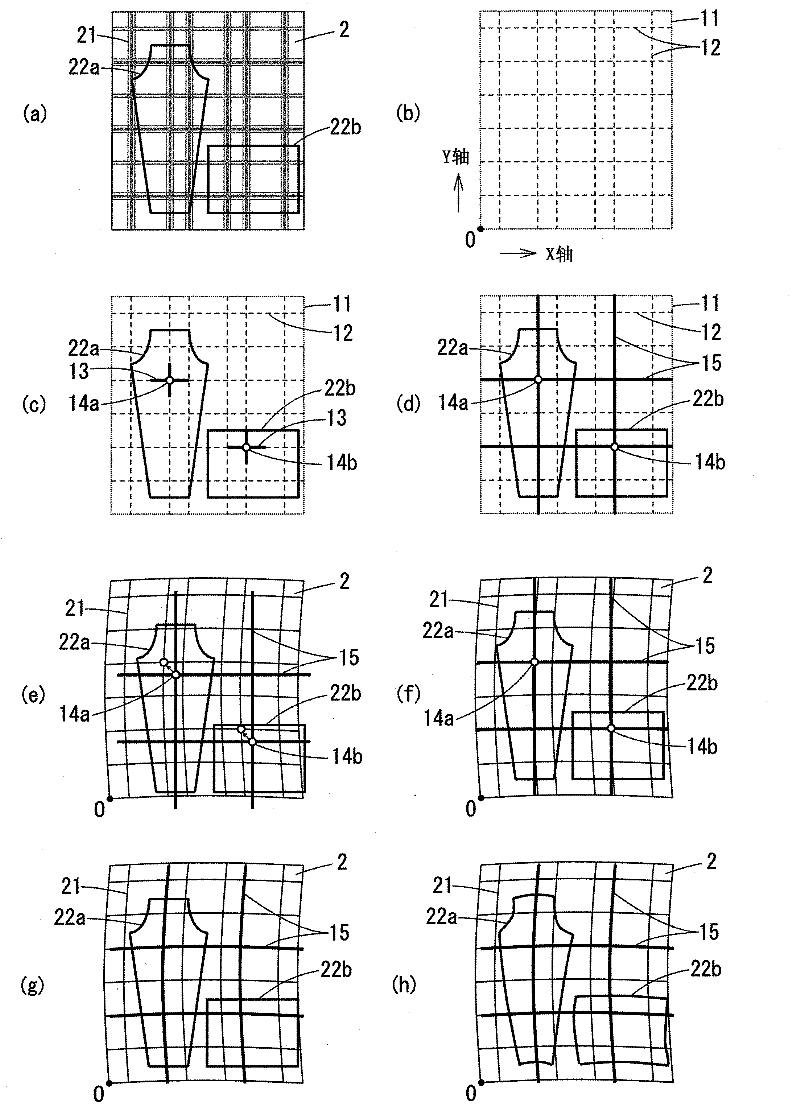

[0144] In Embodiment 1, the cutting of the sheet having the checkered pattern was described, but the processing steps up to cutting are slightly different in the cutting of the sheet having the striped pattern. In this embodiment, refer to Figure 5 , the processing procedure in the case of cutting a sheet having a striped pattern will be described focusing on points different from cutting a sheet having a checkered pattern.

[0145] Figure 5 In (a), the patterns of the parts 22a and 22b to be cut are arranged on the sheet material 2A having the pattern 21A of stripe-like vertical stripes. and figure 2 Similarly, for easy understanding of the description, a state in which two parts are arranged on the square sheet 2A is shown.

[0146] Unlike a checkered pattern, when cutting a sheet with a striped pattern, there is little need to consider pattern matching in a direction parallel to the stripes, so the content of processing when cutting the sheet is different accordingly....

Embodiment approach 3

[0155] When cutting a plurality of parts with different patterns arranged on a sheet, since the reference patterns are scattered and arranged on the sheet, data required for correction of coordinate data are scattered on a virtual plane. On the other hand, when offset occurs in the arrangement of the reference pattern as in the case where the parts of the elongated pattern are offset on the sheet, data required for correction of the coordinate data is insufficient depending on the position.

[0156] When the data of the part pattern is corrected based on such data, the error from the actual deformation increases, and the reliability of the cutting data decreases. In this embodiment, a method of supplementing data when an offset occurs in the arrangement of the reference pattern will be described.

[0157] Image 6 It shows a state in which the theoretical pattern pattern 12B, the patterns 22c to 22f of the respective parts, and the reference pattern are arranged on the virtua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com