Lap former for producing non-woven fabrics

A technology of rolling machine and non-woven fabric, which is applied in the cutting of textile materials, winding strips, textiles and papermaking, etc., can solve the problems of wasting space resources, large volume of cloth rolls, and increasing costs, and save space resources. , Small size, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

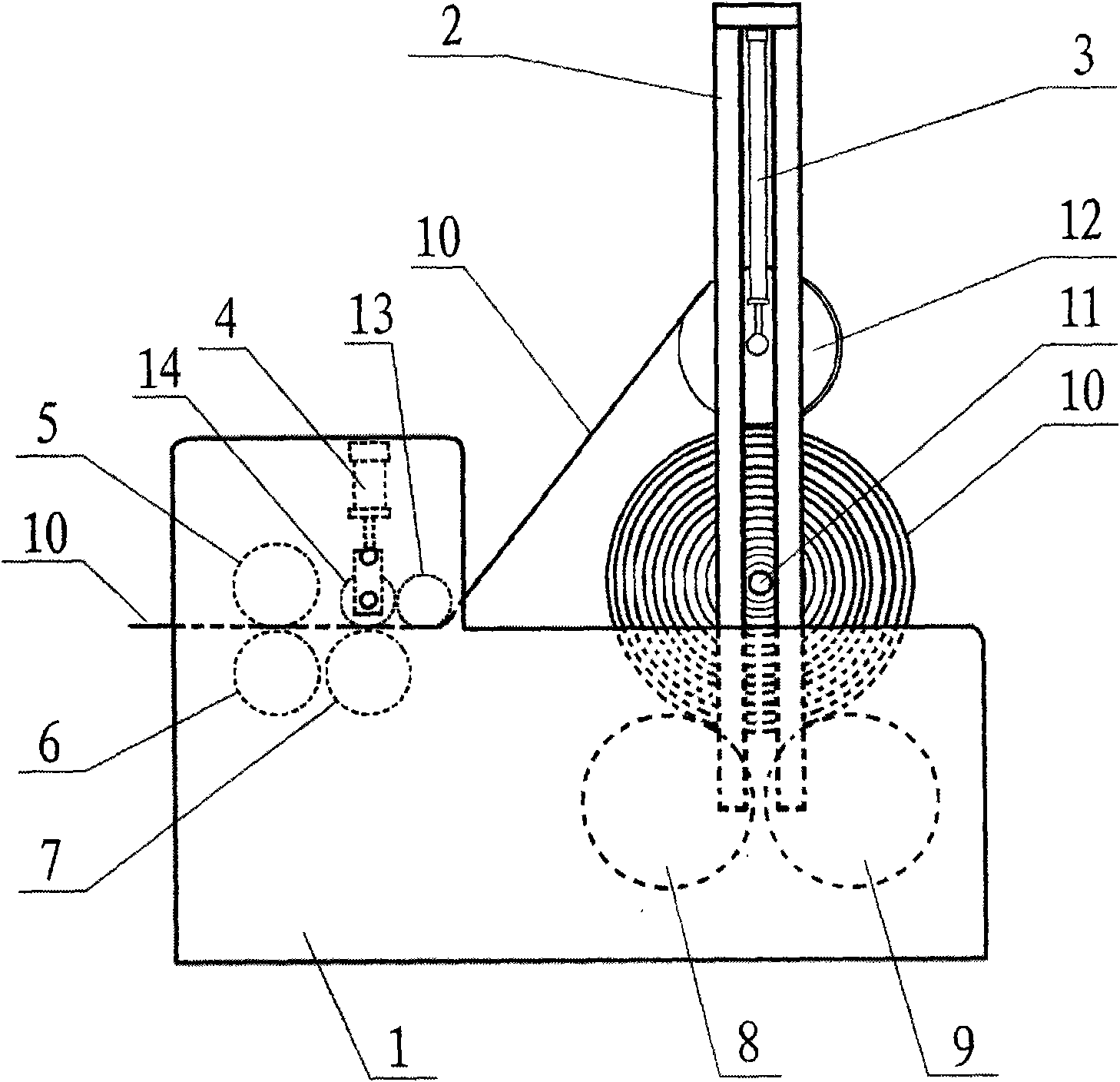

[0013] like figure 1 Shown, from side view, main frame 1 is " L " shape, and six rollers are installed on main frame 1 . The upper nip roller 5 and the lower nip roller 6 clamp the cloth 10 and send it to the upper part of the cutting knife support roller 7, and then change the direction of the cloth 10 through the lower part of the cloth reversing roller 13, and the cloth 10 passes around the outer surface of the pressure roller 12 The position is wound on the cloth winding shaft 11. In order to make the cloth 10 more tightly wound on the cloth winding shaft 11, pressure cylinders 3 are arranged on both sides of the axis of the pressure roller 12, so that the pressure roller 12 can be automatically adjusted according to the thickness of the cloth 10 wound on the cloth winding shaft 11 . In order to fix the cloth winding shaft 11 and the pressure cylinder 3 conveniently, a cylinder frame 2 is arranged on the inner side of the main frame 1, and the center point of the cloth w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com