Fiber-woven flexible composite traction belt for elevator and manufacturing method thereof

A fiber weaving and manufacturing method technology, applied in elevators, braids, textile cables, etc., can solve the problems of repeated bending and loading of unfavorable steel wire ropes, affecting service life and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical content and implementation of the present invention will be further described below in conjunction with the accompanying drawings.

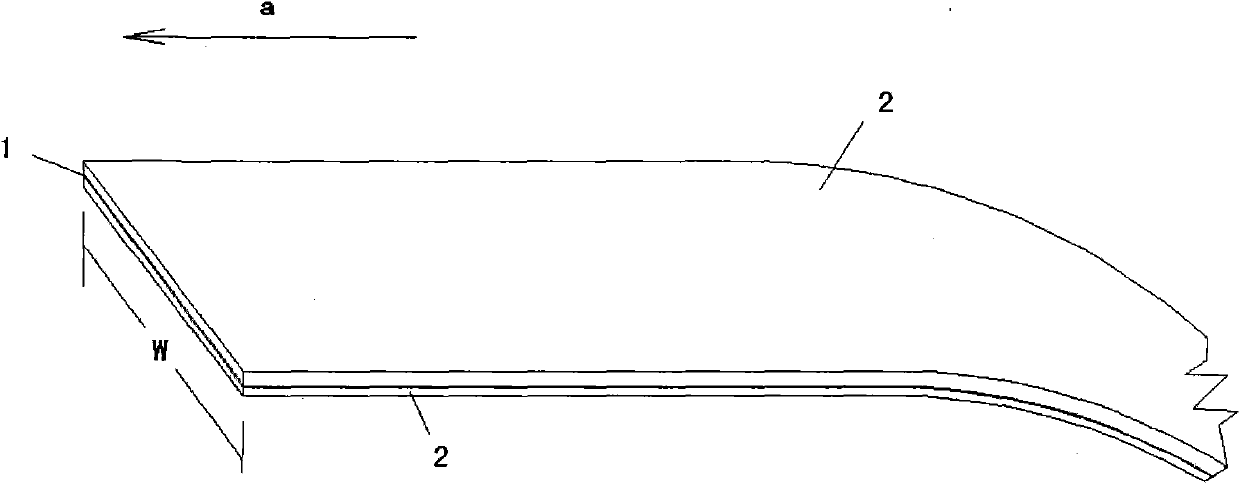

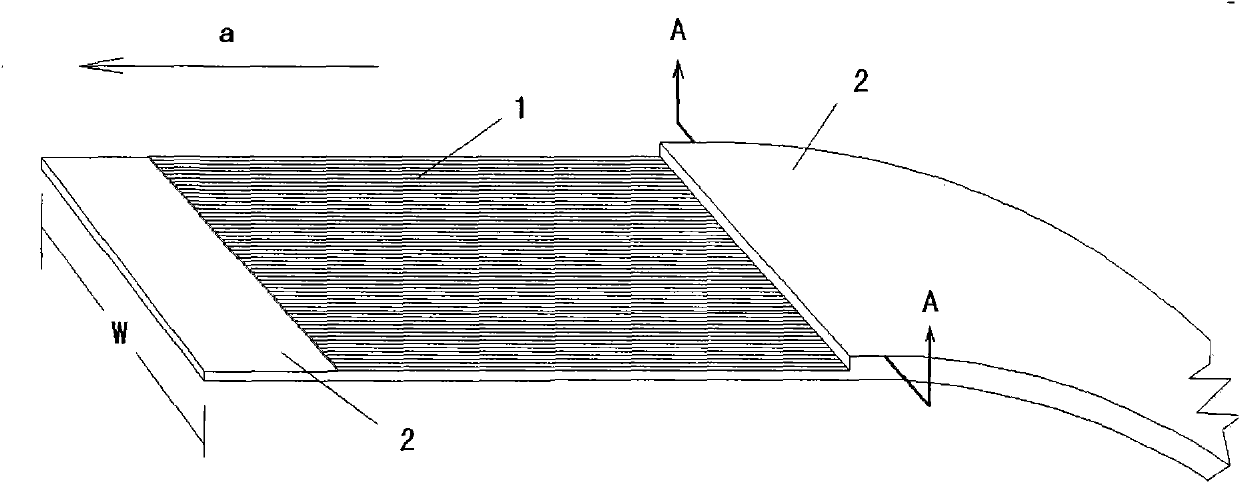

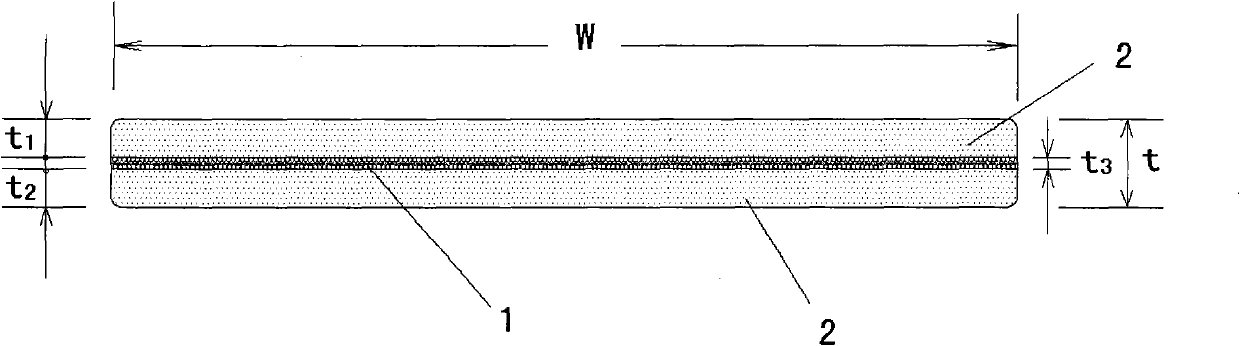

[0019] figure 1 It is a partial three-dimensional schematic diagram of the fiber-woven flexible composite traction belt for elevators of the present invention; in the figure, the fiber-woven belt 1 is woven from steel wire, aramid fiber, glass fiber, ceramic fiber or carbon fiber in some form. The method can be in many forms. The best solution of the present invention is to use the form of woven unidirectional fiber cloth as the arrangement method, that is, most of the fibers of the woven belt are arranged in a manner parallel to the length direction a of the woven belt, only A few fibers are weaving at a certain angle to the a direction. Combine Figure 4 As shown, the fiber monofilament or the fiber bundle 16 composed of multiple monofilaments are parallel to the length direction a of the braided belt, or except for most of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com