A Dynamic Measurement and Feedback Method of Hydraulic Tension Force of Belt Conveyor

A belt conveyor and dynamic measurement technology, which is applied to conveyors, conveyor objects, conveyor control devices, etc., can solve problems such as inaccurate tension measurement, achieve stable operation, accurate measured values, and avoid effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The electrical control system also includes an alarm device connected to the electrical control cabinet; when the difference between the measured driving force and the calculated driving force exceeds a set threshold, the electrical control cabinet controls the frequency converter of the drum to stop and start an alarm at the same time The device alarms.

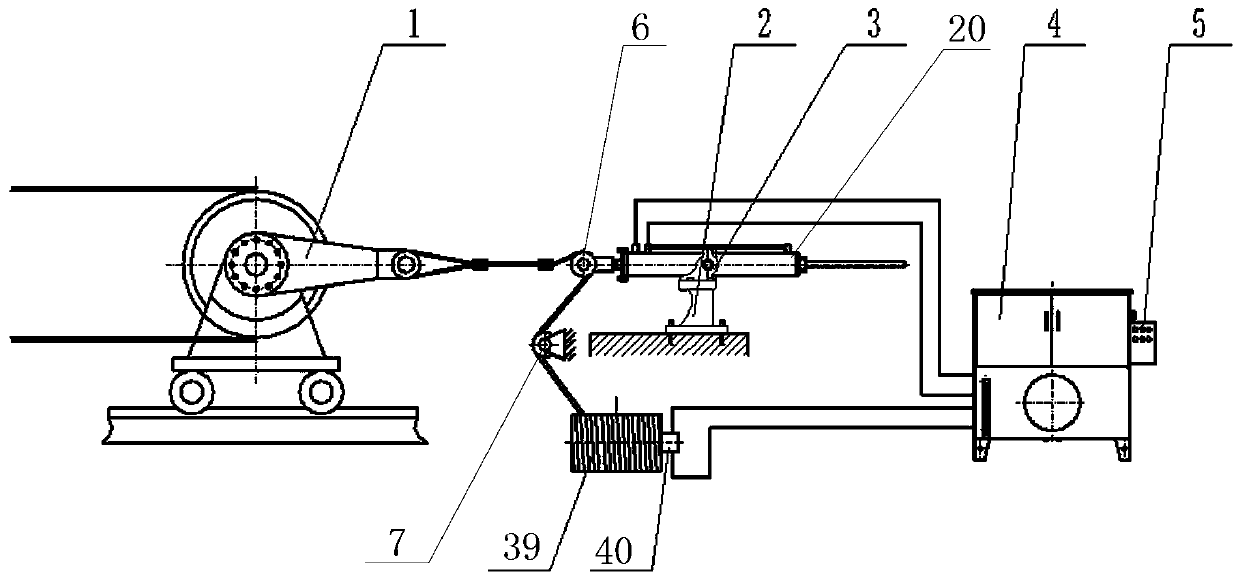

[0044] The hydraulic system includes an oil tank, an oil supply circuit connected to the oil tank, and the first and second servo reversing valves; the oil supply circuit includes a main oil outlet circuit, two branch oil outlet circuits and two branch oil return circuits; the main outlet oil circuit One end of the oil circuit is connected to the fuel tank, and the other end is divided into two circuits and respectively connected to two servo reversing valves. A hydraulic pump and a check valve are connected in series on the main oil outlet circuit; the two branch oil outlet circuits include the first oil outlet Road ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com