Manufacturing method and equipment of disposable anti-galactorrhea bra

A technology for manufacturing equipment and manufacturing methods, which is applied to tools for sewing clothes, bras, and clothing, etc., can solve the problems of uneven quality, immature processing technology, and few people who use disposable anti-galactorrhea bras, and achieve The effect of low cost, low manufacturing cost and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

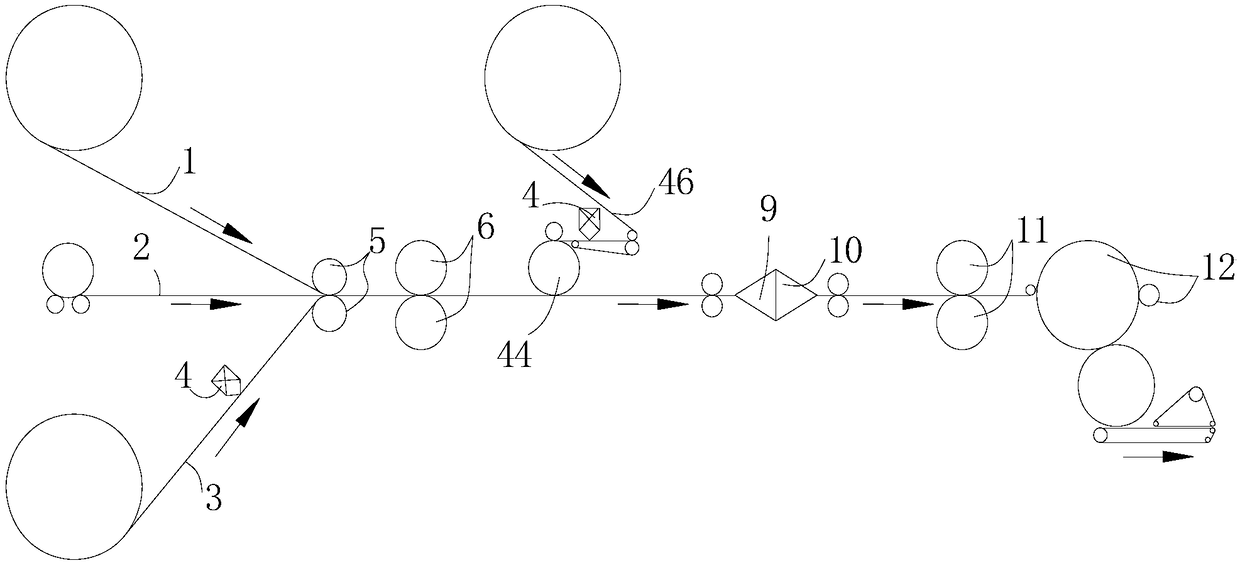

[0048] The manufacture method of a kind of disposable anti-galactorrhea corset of present embodiment, as figure 1 shown, including the following steps:

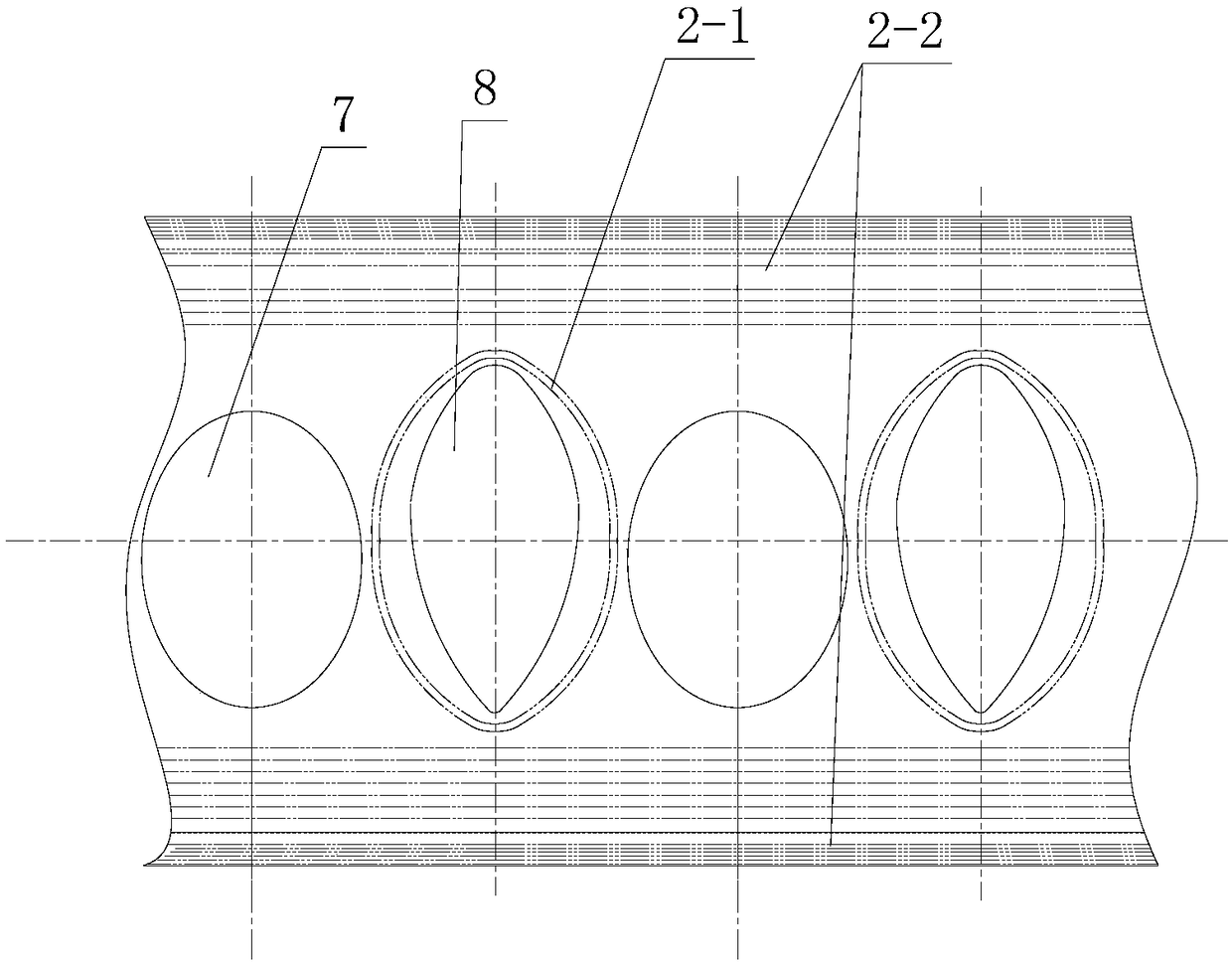

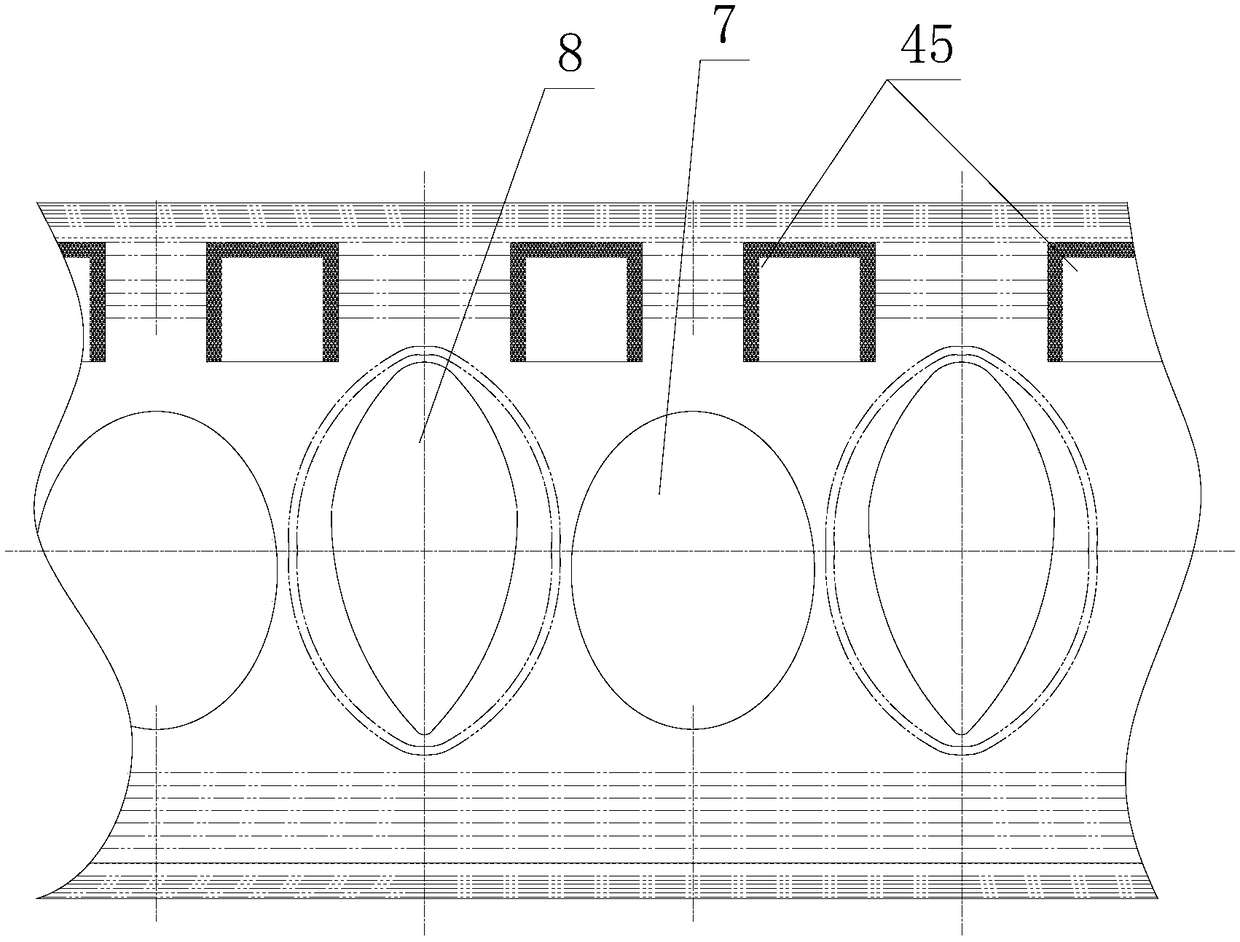

[0049] (1) Material compounding: the inner layer non-woven fabric 1, the elastic band 2 and the outer layer non-woven fabric 3 are sequentially superimposed and glued together from top to bottom to form a continuous composite; Sizing is carried out on the surface of the non-woven fabric, and the inner layer non-woven fabric, the elastic band and the outer layer non-woven fabric are compounded by the composite roller group 5; figure 2 As shown, the elastics include O-shaped elastics 2-1 and linear elastics 2-2. Along the conveying direction of the outer non-woven fabric, there are multiple groups of O-shaped elastics distributed in the middle of the outer non-woven fabric. The O-shaped elastic includes two O-shaped elastics arranged concentrically inside and outside, and a set of linear elastics are provided on the left and ...

Embodiment 2

[0056] This embodiment is a kind of manufacturing equipment for the disposable anti-galactorrhea bra of the method described in embodiment 1, such as figure 1As shown in the direction of the arrow, along the conveying direction of the material, it includes the material unwinding mechanism, compound roller group, cutter forming device, cutter compound device, half-folding mechanism, turning mechanism, sealing and pressing device and cutting transfer device connected in sequence. One side of the knife composite device is equipped with a pocket non-woven fabric unwinding roller; the material unwinding mechanism is equipped with an inner non-woven fabric unwinding roller, an elastic unwinding roller and an outer non-woven fabric unwinding roller. The inner layer of non-woven fabric, elastic band and outer layer of non-woven fabric sent out by the rolling mechanism are compounded by the composite roller group to form a composite body. The device cuts out the anti-galactorrhea pad p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com