Wire cutting device for swwing machine

A sewing machine and thread cutting technology, which is applied to sewing machine components, thread cutting mechanisms in sewing machines, sewing equipment and other directions, can solve problems such as large driving force, and achieve the effects of improving reliability, realizing miniaturization, and preventing poor action.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] (overall structure of the embodiment)

[0035] Hereinafter, the thread cutting device 100 (hereinafter, simply referred to as the thread cutting device 100 ) of the sewing machine according to the embodiment of the present invention will be described in detail with reference to FIGS. 1 to 12 .

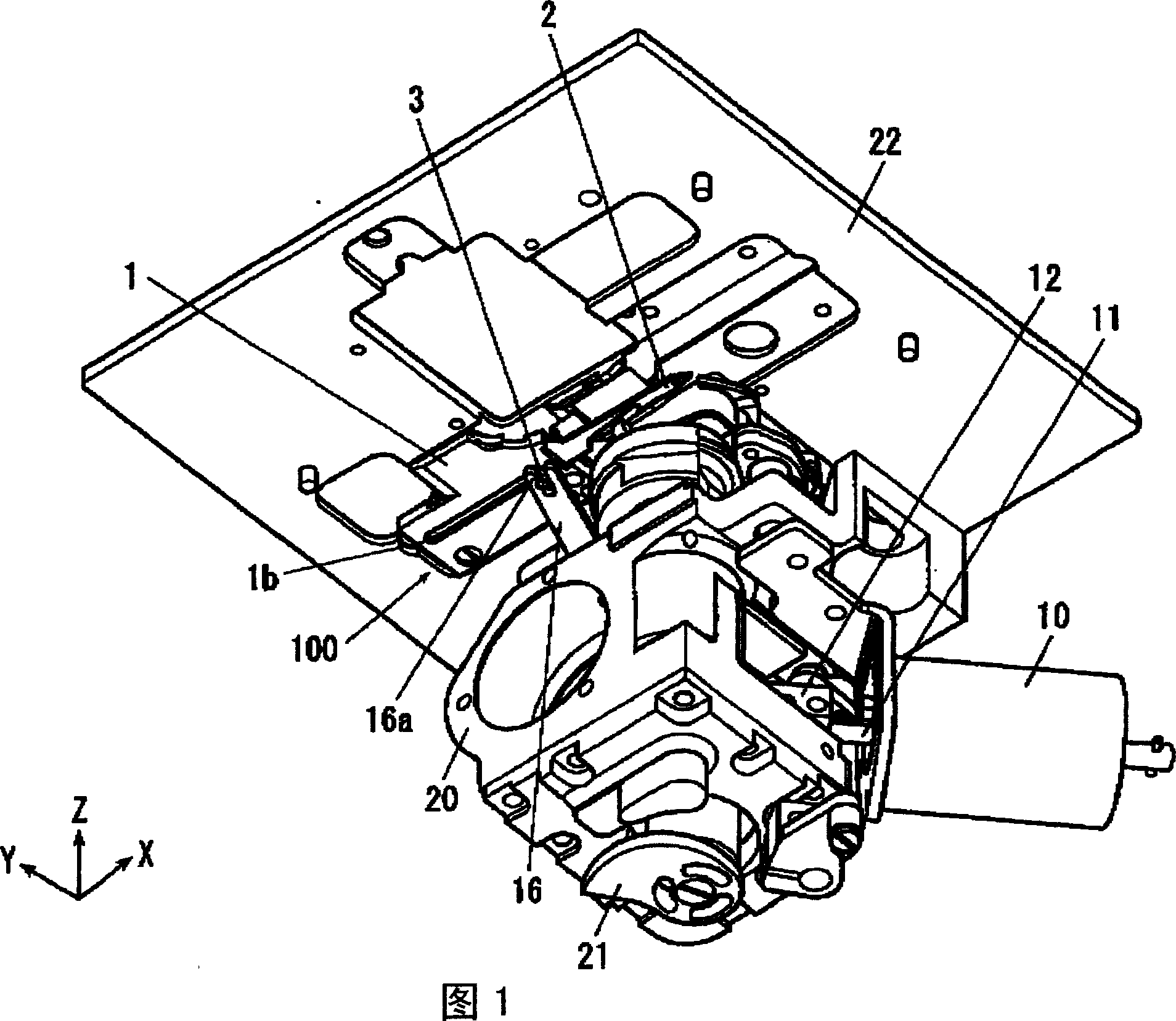

[0036] As shown in FIG. 1 , the thread cutting device 100 according to the present embodiment is mounted on the lower surface of the needle plate 22 disposed near the needle drop position along the upper surface of the sewing machine floor (not shown).

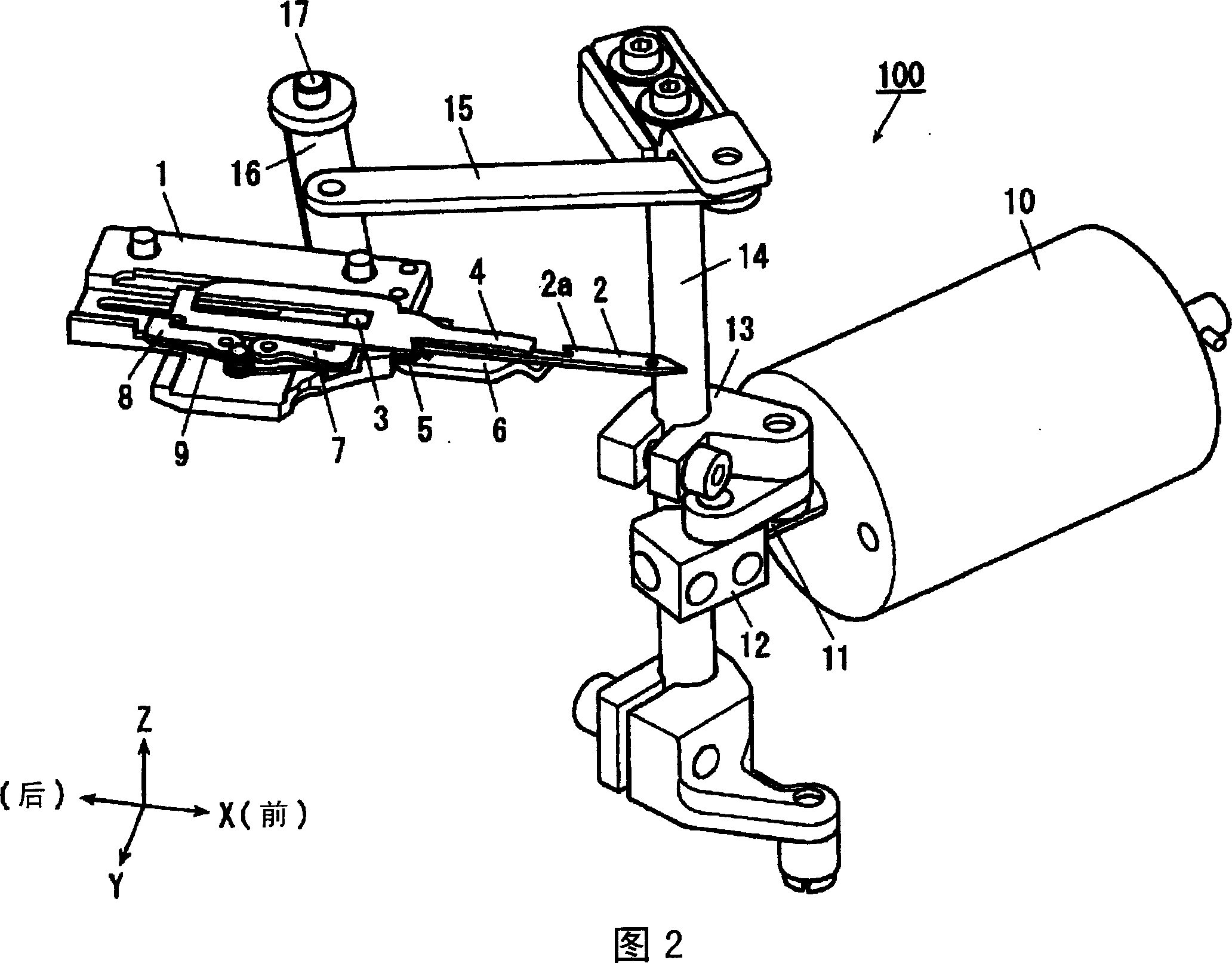

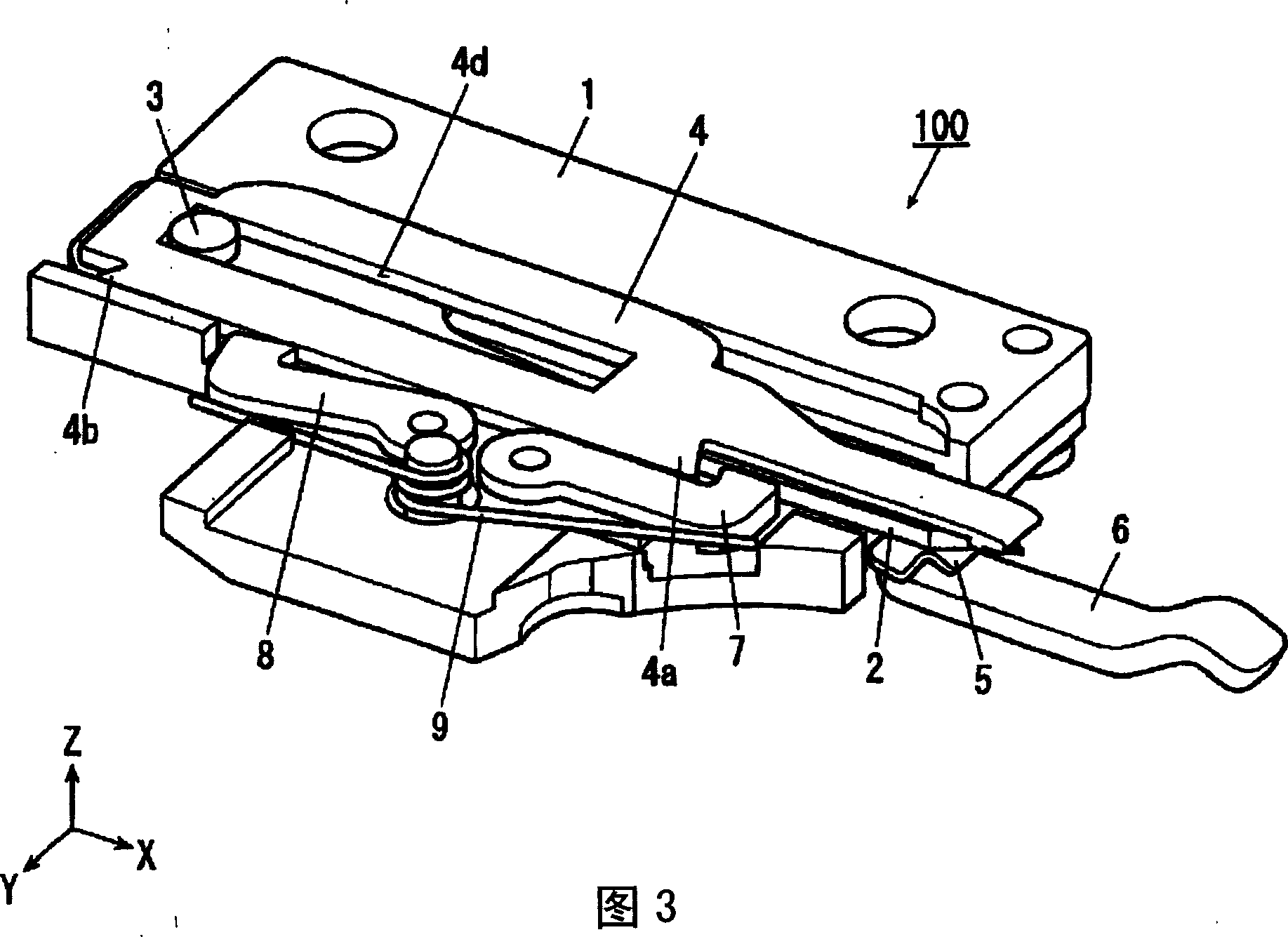

[0037] As shown in FIG. 2 , the thread cutting device 100 has: a movable cutter 2 that reciprocates between a standby position and a thread catching position; The fixed knife 4 that moves back and forth and cooperates with the movable knife 2 to cut the sewing thread at the active position, the front stopper 7 that keeps the fixed knife 4 at the standby position, and keeps the fixed knife 4 in the active position. position of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com