Lost foam wire cutting numerical control machining shaping mill

A technology of forming and wire cutting, applied in metal processing and other directions, can solve the problems of low forming speed and single function, and achieve the effect of complete functions and compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

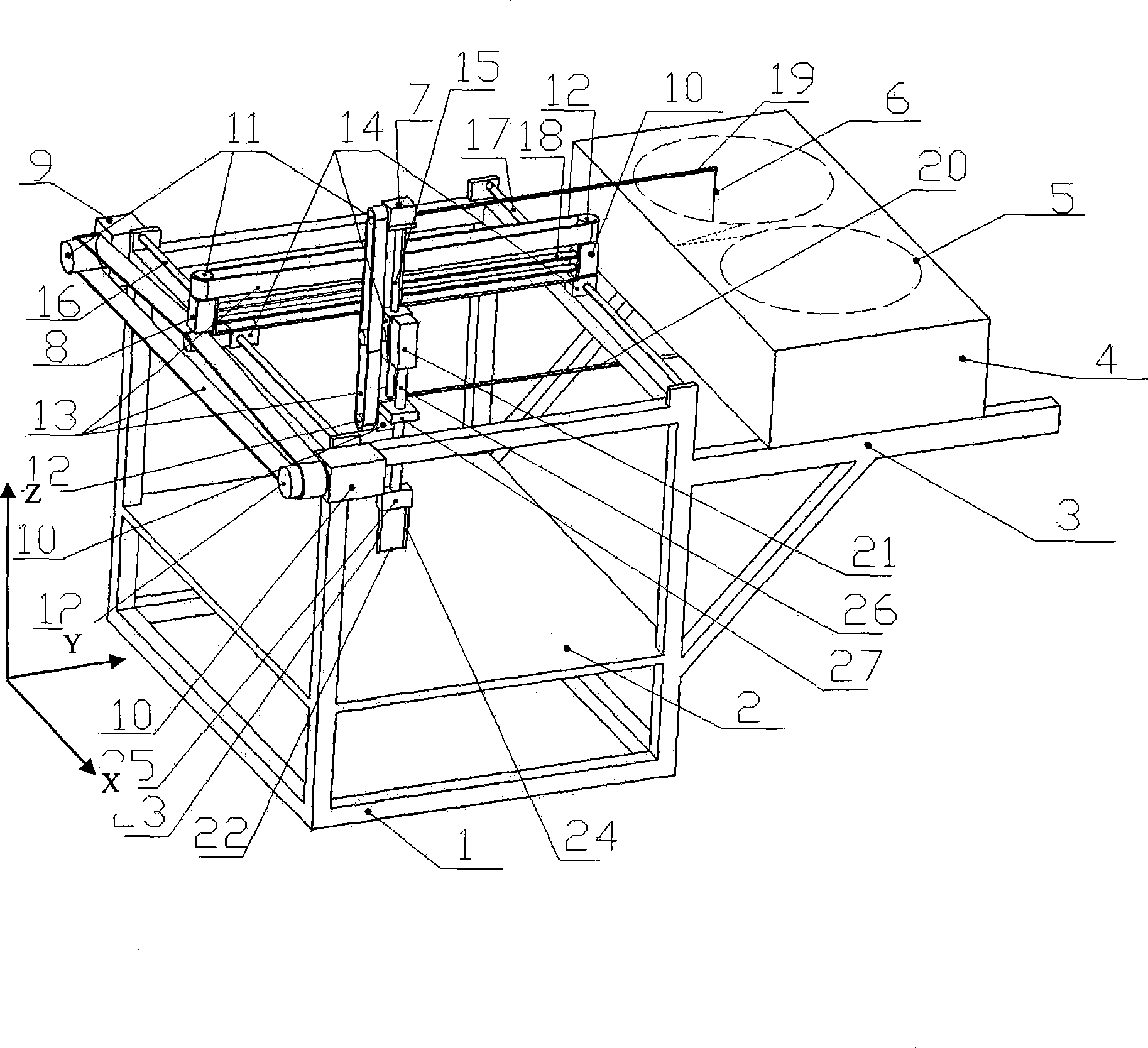

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

[0023] Such as figure 1 As shown, the present invention is composed of a mechanical part and a control part. The mechanical part includes a frame 1, a tray 2, an X-axis motor 9, a Y-axis motor 8, a Z-axis motor 7, an X-axis left cylindrical guide rail 16, and an X-axis right cylindrical guide rail. 17. Y-axis cylindrical guide rail 18, Z-axis cylindrical guide rail 15, spindle motor 21, spindle 26; the frame 1 is a rectangular three-dimensional frame, the tray 2 is located in the frame 1, the X-axis left cylindrical guide rail 16 and the X-axis right cylindrical The guide rails 17 are parallel and are respectively located on both sides of the X direction on the upper end of the frame 1. The X-axis left cylindrical guide rail 16 and the X-axis right cylindrical guide rail 17 are respectively pierced with sliders, and the Y-direction beams are fixed on the two sliders; f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com