Forming conveying method and equipment for disposable briefs-type sanitary products

A technology for sanitary products and conveying equipment, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of high equipment cost, reduced production efficiency, and complicated conveying process, so as to improve production efficiency, shorten time, The effect of improving operation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

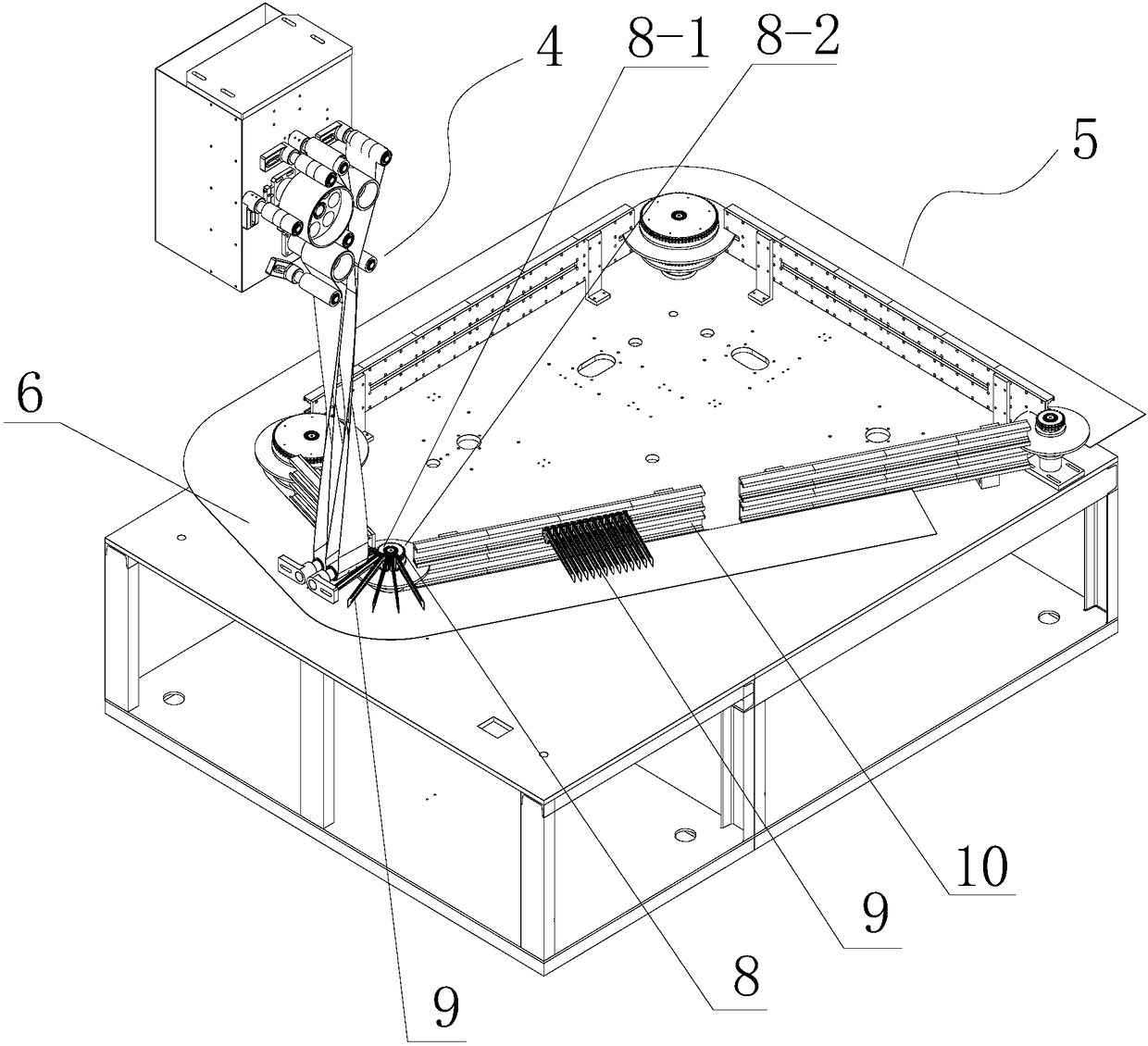

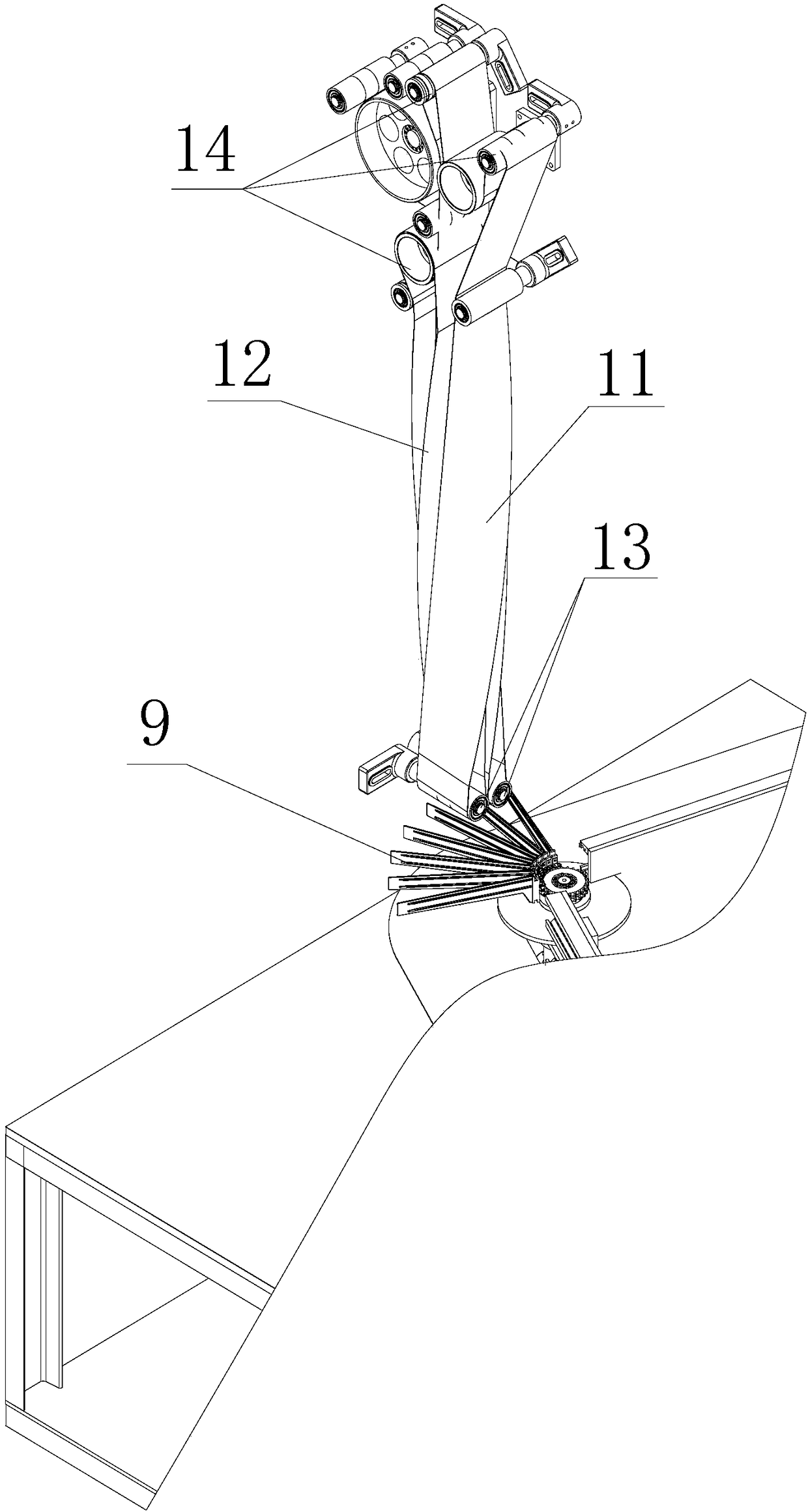

[0041] This embodiment is a molding and conveying method for disposable pants-type sanitary products. After the product is formed, it is sent to the top of the stacking device by a twisting conveying mechanism, and then sent to the collection station of the stacking device one by one along the width direction of the product. The stacking unit collects and sends out the stack. Wherein, when the product is sent into the collecting station of the stacking device, the product is vertically positioned above the stacking device, and the product is vertically inserted into the collecting station along its width direction. When the product is formed, the initially formed product after compounding (such as Figure 6 Shown) side seal pressure first, and then cut off (such as Figure 7 shown) and transferred to the twist conveyor mechanism.

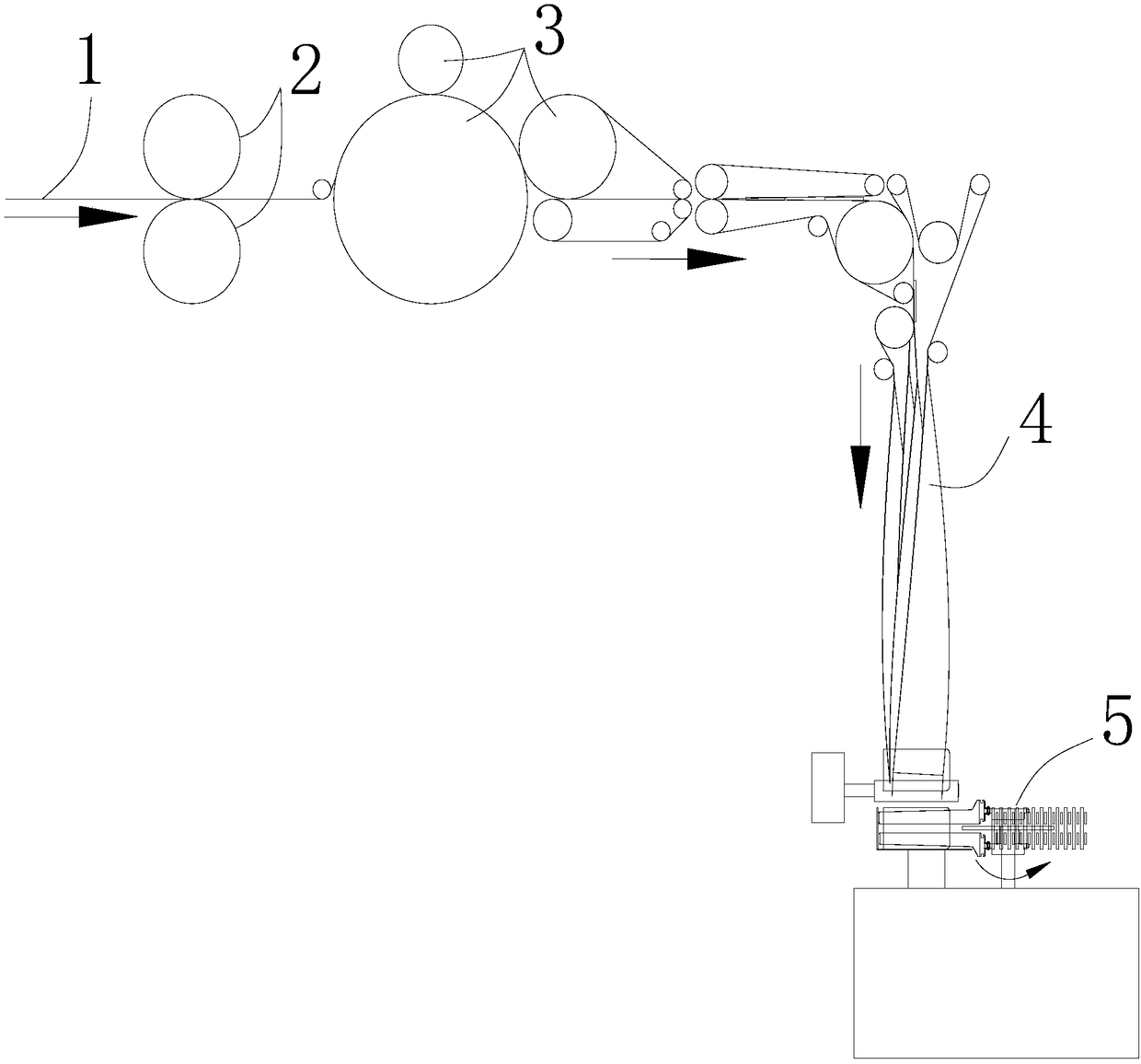

[0042] Forming and conveying equipment for disposable pants-type sanitary products for realizing the above method, such as figure 1 As shown, ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com