Diced meat cutting machine

A cutting machine and diced meat technology, which is applied in metal processing and other fields, can solve problems such as difficult cleaning, uneven diced meat, and heavy equipment load, and achieve the effects of easy maintenance of equipment, saving the number of motors, and high meat cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

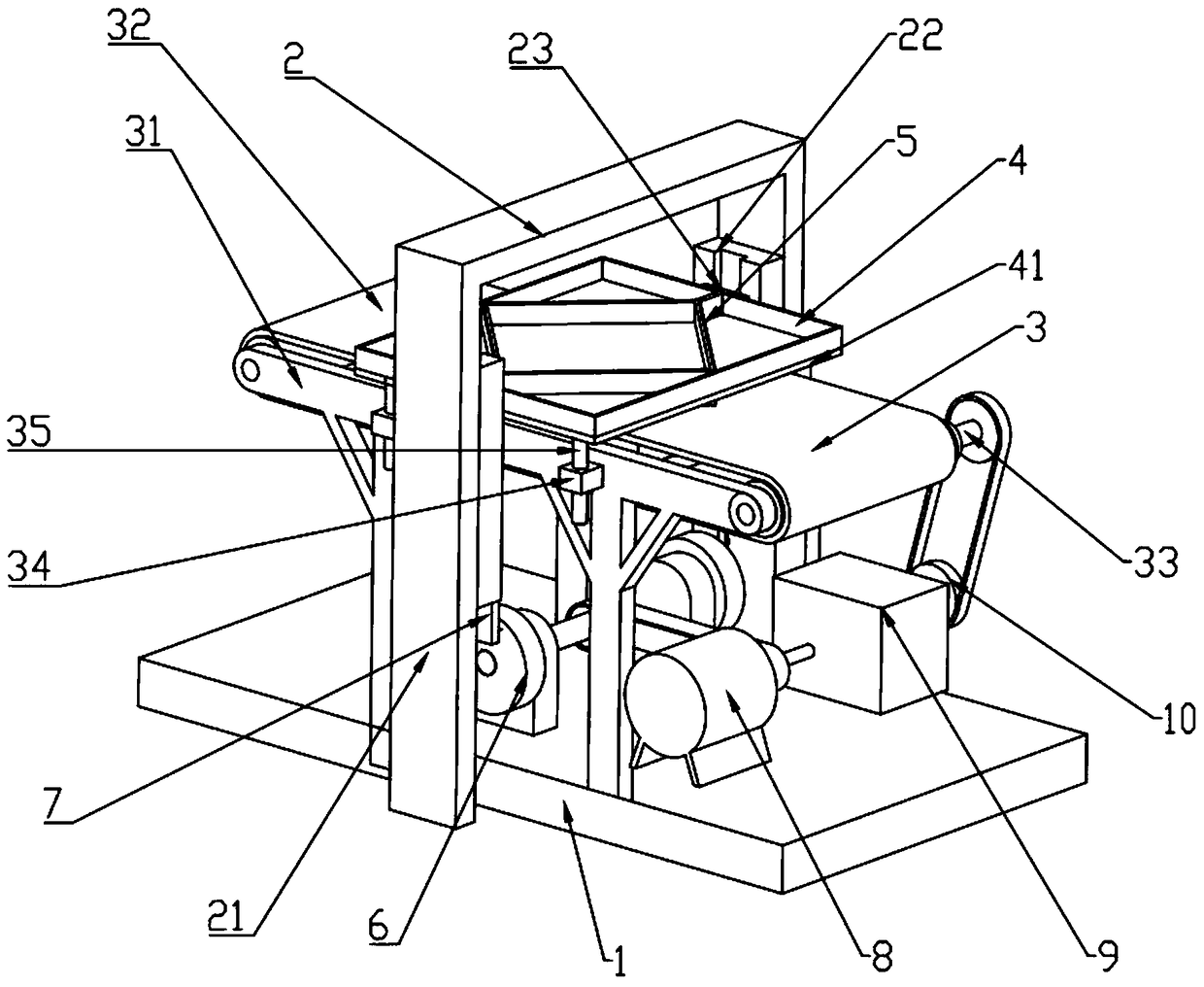

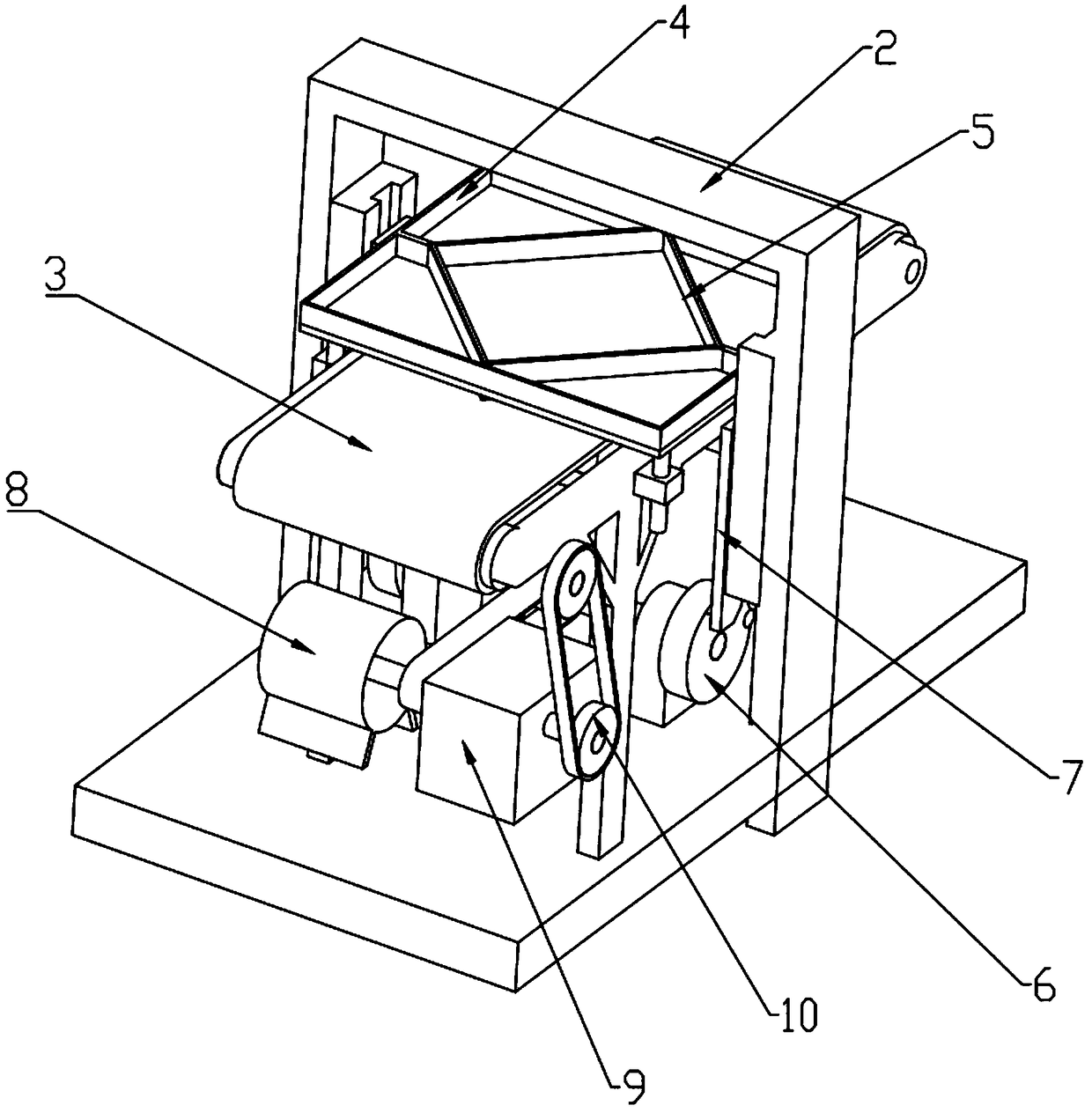

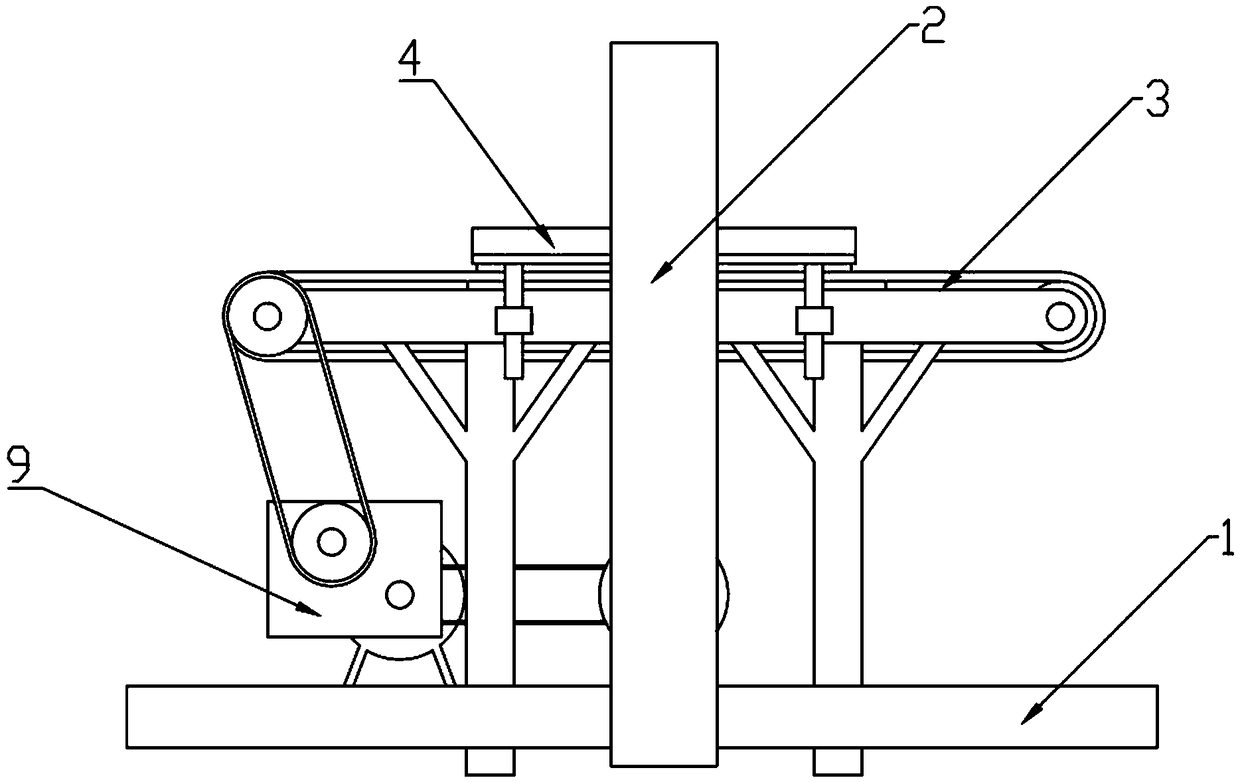

[0020] Such as Figure 1 to Figure 3 As shown, a kind of diced meat cutting machine according to the present invention comprises a base 1, a gantry 2 is installed on the base 1, a conveyor belt mechanism 3 is arranged in the gantry 2, and the conveyor belt mechanism 3 is installed on the machine base 1, a knife rest 4 is slidably connected to the inside of the gantry 2 along the vertical direction, a chute 22 is provided on the inside of the vertical beam 21 of the gantry 2, and the two knife rests 4 The side is fixedly provided with the slide block 23 that cooperates with chute 22, and described knife rest 4 is positioned at the top of described conveyor belt mechanism 3, and a diamond-shaped blade 5 is fixed in described knife rest 4, and described knife rest 4 is a square frame, The blade 5 is fixed in the knife rest 4, the four c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com