Improved food cross-cutting device

A cross-cutting device and improved technology, applied in the fields of food science, cocoa, metal processing, etc., can solve the problems of materials that cannot be cut, reduce cutting accuracy, and large noise, improve cutting stability and reliability, and improve work. Efficiency, the effect of reducing operating noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

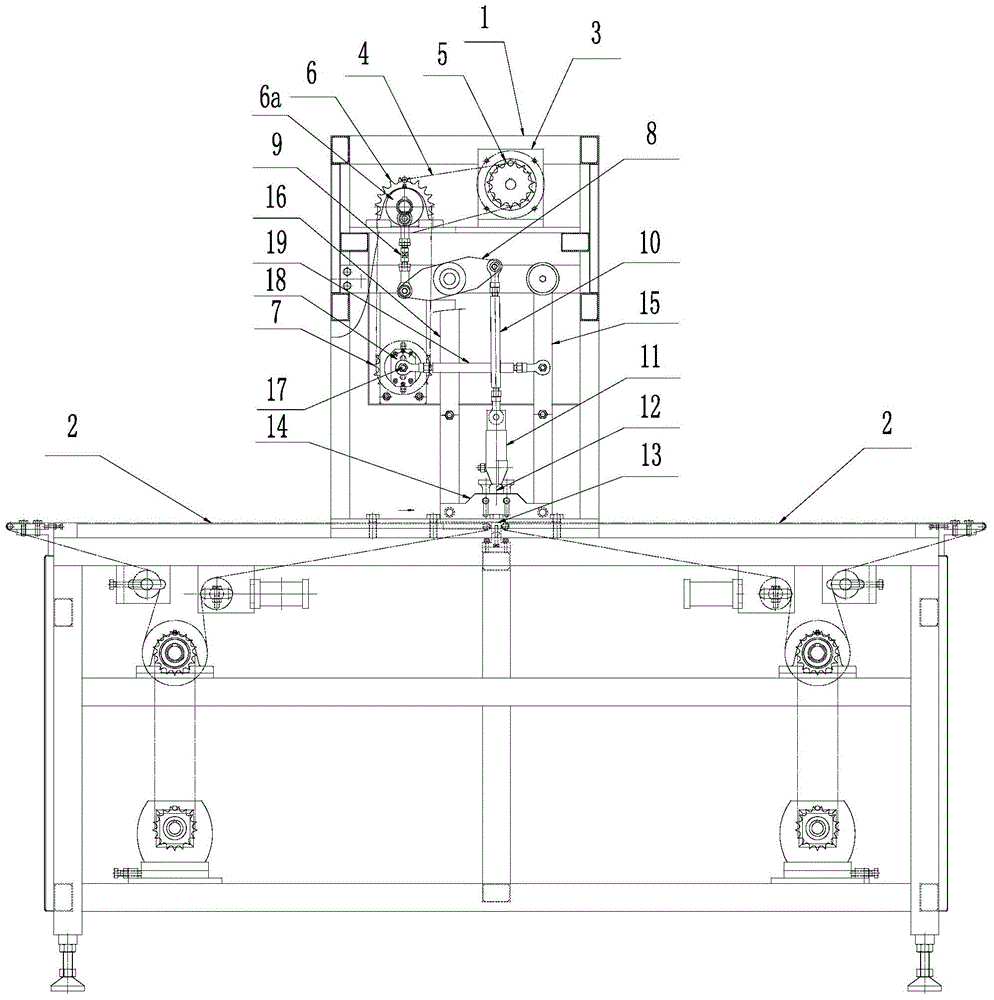

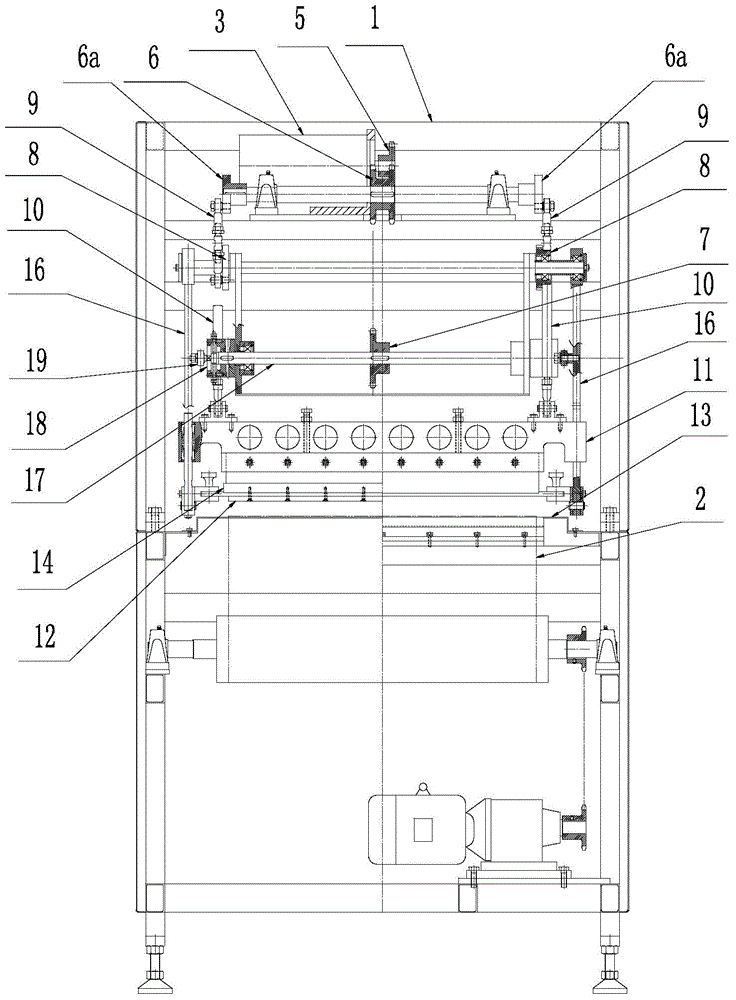

[0030] Example: Combine figure 1 and figure 2 As shown, it is a specific embodiment of the improved food cross-cutting device provided by the present invention, which is composed of three parts: a frame 1, a material conveying mechanism arranged on the frame 1, and a cutter driving mechanism.

[0031] The material conveying mechanism is two groups of transmission belts 2 arranged continuously in gaps (the active synchronous wheels in each group of transmission belts 2 in this embodiment are driven by the motor sprocket mechanism at the bottom), it must be pointed out, of course, that the transmission belt 2 The driving part is a known technology, which will not be described in detail in this embodiment. The major changes of the present invention are:

[0032] The composition of described cutter drive mechanism is: drive motor 3, sprocket transmission mechanism, cutter up and down movable mechanism and cutter swing mechanism, and wherein sprocket transmission mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com