Improved food cross-cutting device

A cross-cutting device and an improved technology, applied in food science, cocoa, metal processing, etc., can solve the problems that materials cannot be cut, the working environment is noisy, and the cutting accuracy is reduced, so as to improve cutting stability and reliability, and run High reliability and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

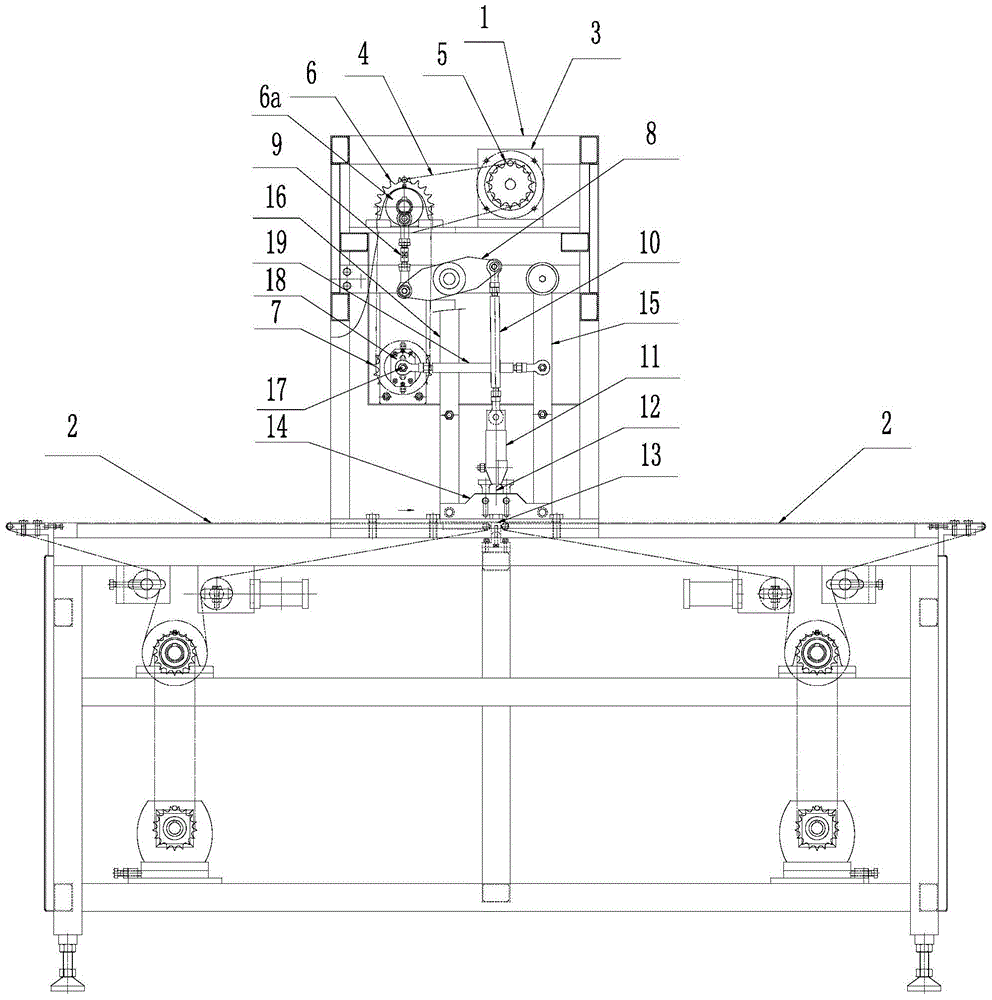

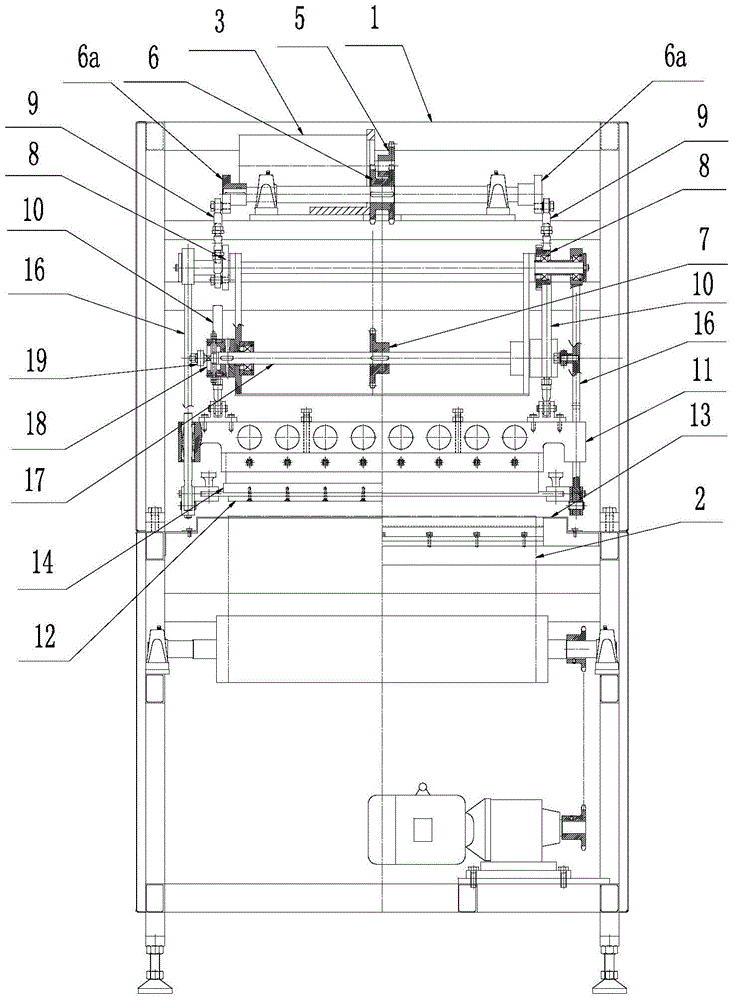

[0030] Example: Combining Graphs 1 and diagram 2 As shown, it is a specific embodiment of the improved food cross-cutting device provided by the present invention, which consists of a frame 1 , located in the rack 1 The upper material conveying mechanism and the cutter driving mechanism are composed of three parts.

[0031] The material conveying mechanism is two sets of transmission belts arranged continuously in gaps 2 (Each group of drive belts in this embodiment 2 The active synchronous wheels in the drive are all driven by the motor sprocket mechanism at the bottom), of course it needs to be pointed out that the drive belt 2 The driving part is a known technology, and it will not be described in detail in this embodiment. The major changes of the present invention are:

[0032] The composition of the cutter drive mechanism is: drive motor 3 , sprocket drive mechanism, cutter up and down movement mechanism and cutter swing mechanism, wherein th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com