Turntable intersection degree and verticality measurement device and method

A measurement device and measurement method technology, applied in the direction of measurement devices, optical devices, instruments, etc., can solve the problems of disassembly and assembly errors, installation errors, complicated methods, etc., achieve good anti-interference and stability, avoid contact deformation, Optimizing the effect of the measurement process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

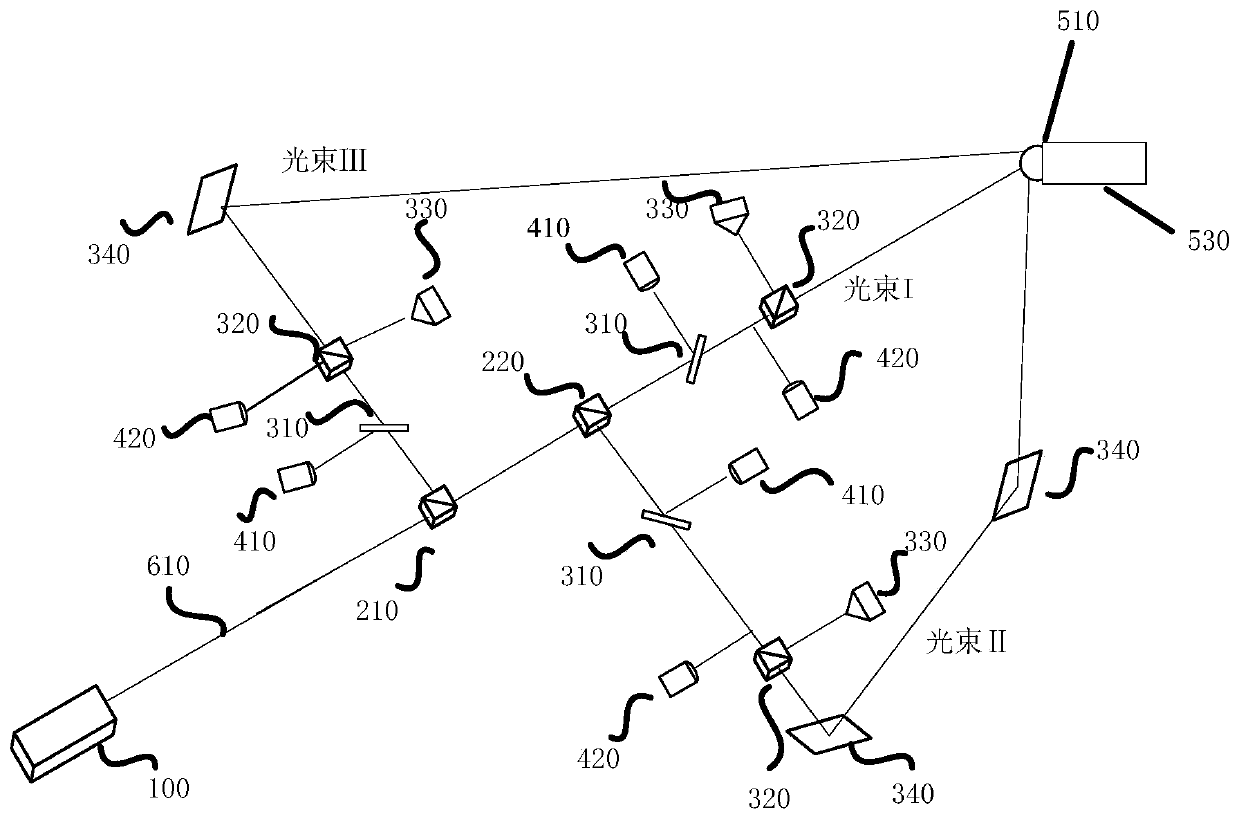

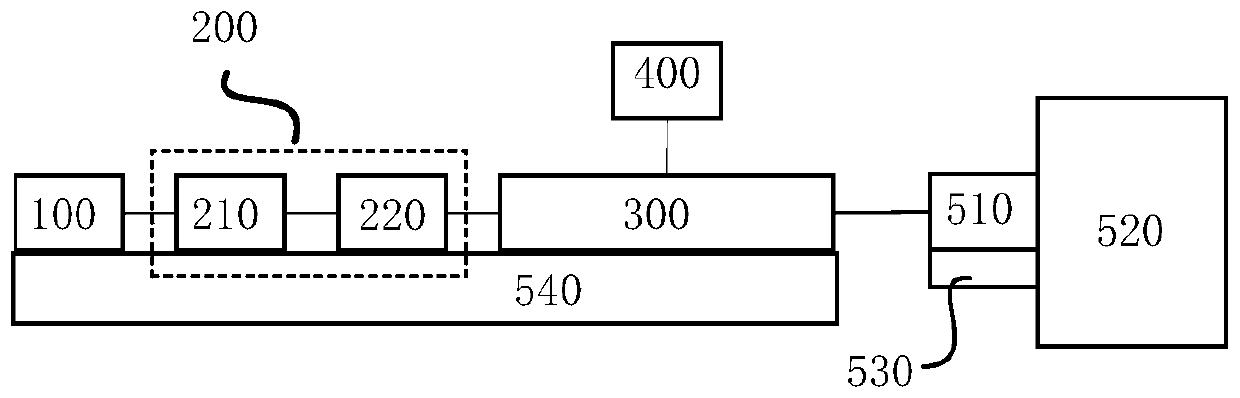

[0068] The invention is applied to a five-axis turntable intersection degree and perpendicularity on-site measuring device based on the cat's eye dual-frequency laser interference phase measurement technology. Considering that the five-axis center of the turntable is at the same position, the cat’s-eye reflector is designed as a common target for five-axis measurement. It is fixed at the center of the axis by a fixture, and the five-axis intersection and perpendicularity measurement can be continuously realized without disassembling the turntable.

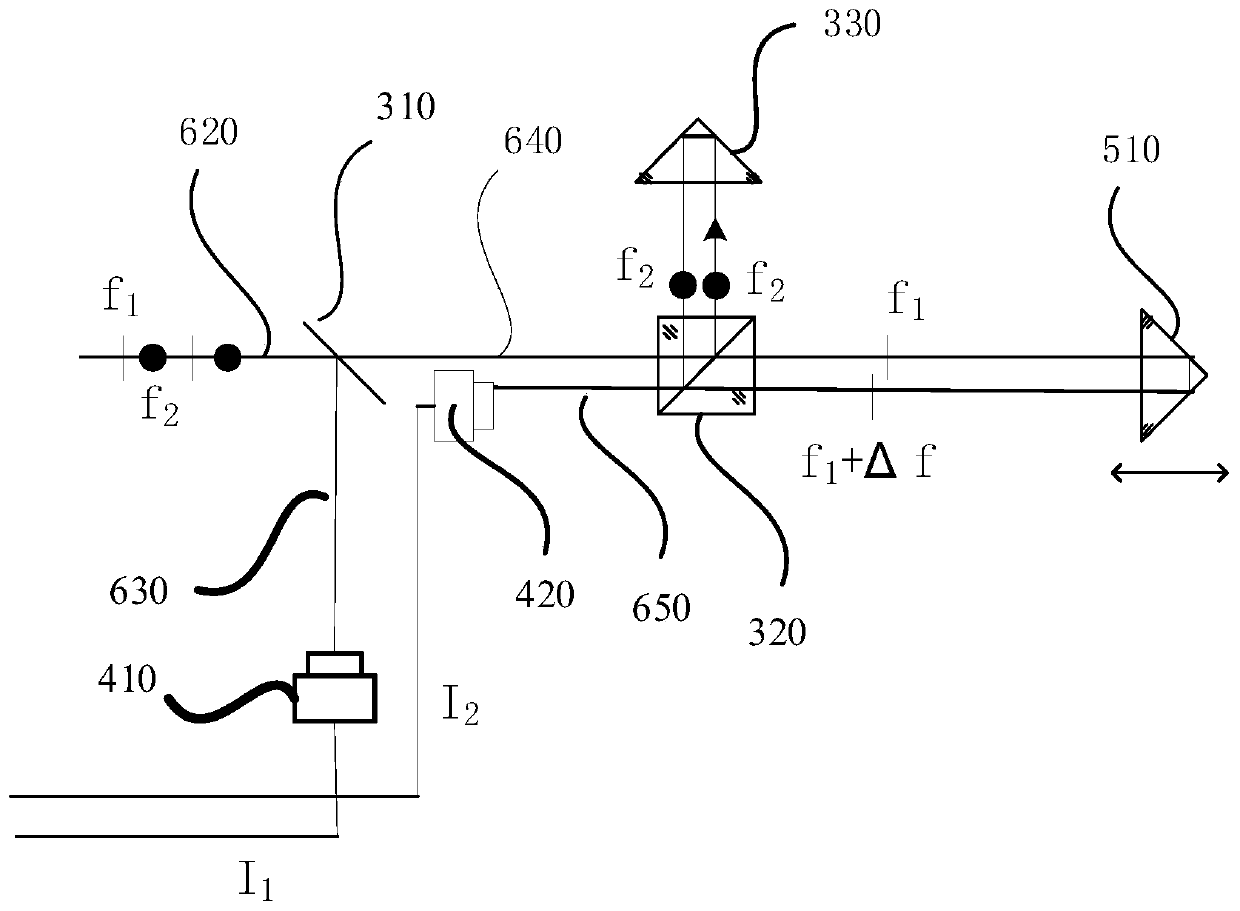

[0069] Using a dual-frequency laser interferometric phase measurement device based on cat's eye, it consists of a dual-frequency laser head 100, a beam splitter with 30% reflectivity, a beam splitter with 50% reflectance, a three-way interference optical path assembly 300, a cat's eye reflector, a phase sensor and a cat's eye Installation fixtures and other components. The dual-frequency laser head simultaneously generates two line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com