Cut-off removed device

A technology of suction device and cutting roller, which is applied in metal processing and other directions, and can solve problems such as unsuitability for high-speed operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

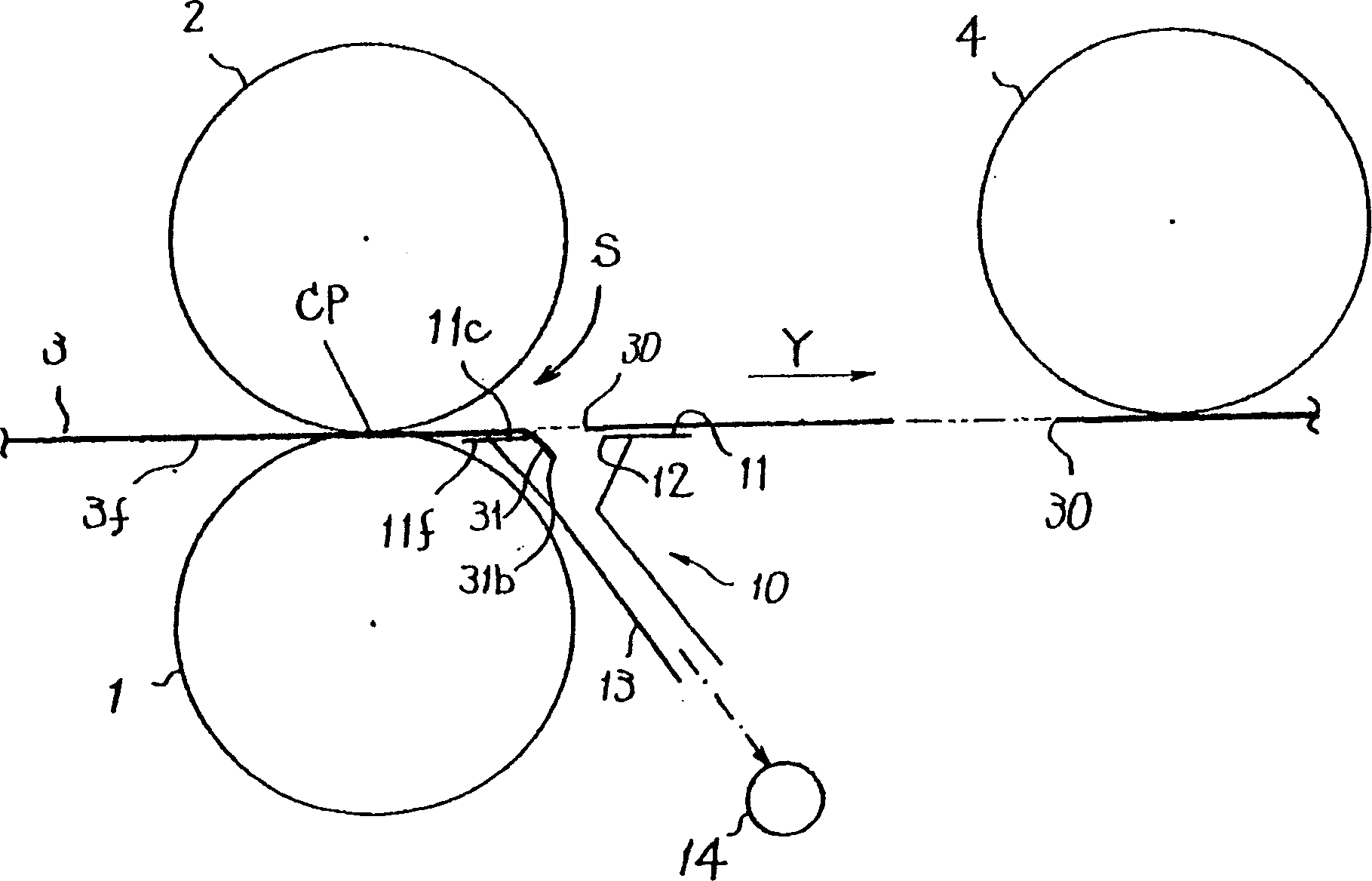

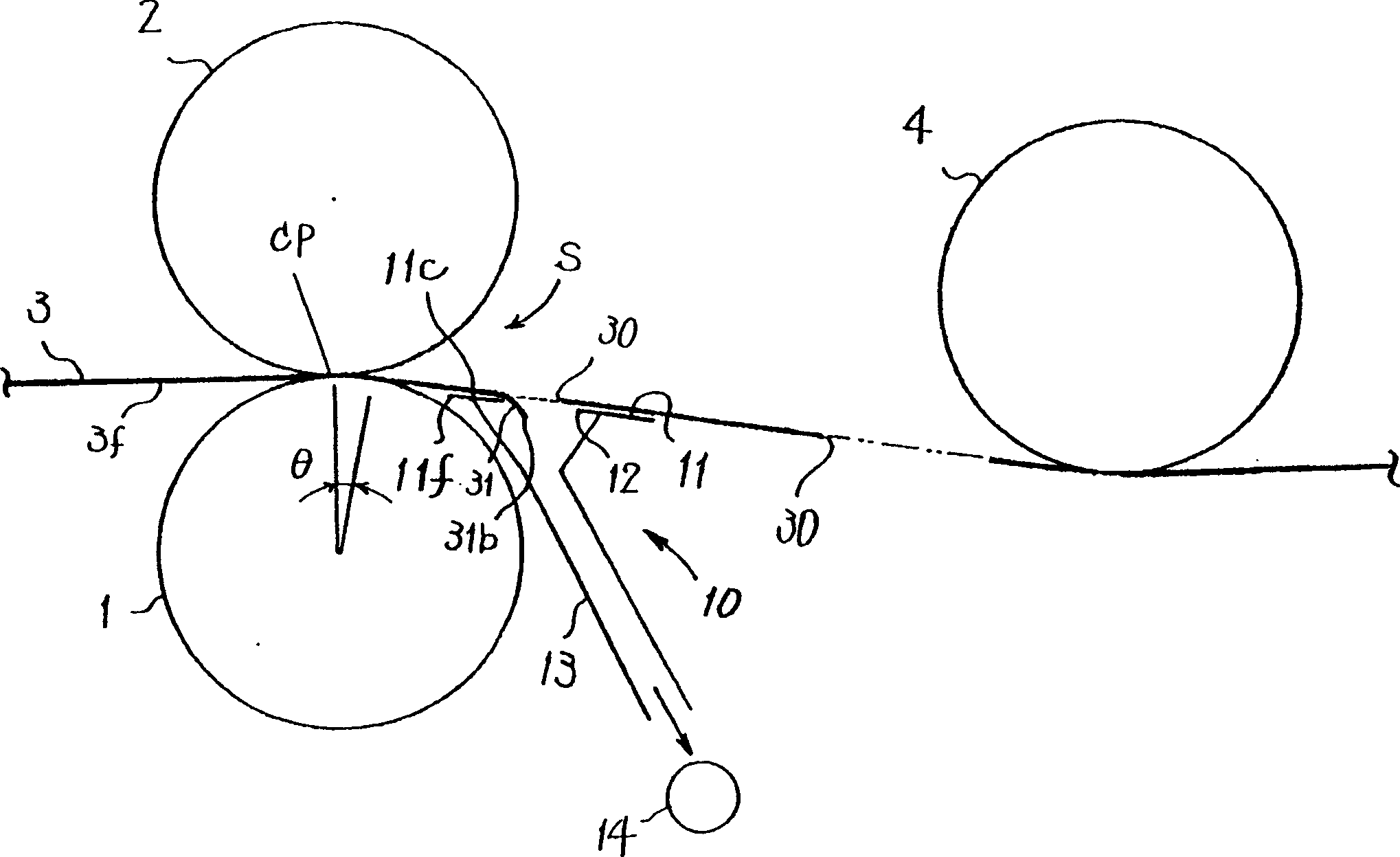

[0024] Hereinafter, an embodiment of the present invention will be described with reference to the drawings.

[0025] figure 1 In the process, a strip (sheet) 3 is continuously supplied between an anvil roll 1 and a cutting roll 2 . When the strip material 3 passes between the cutting roll 2 and the anvil roll 1, the strip material 3 removes the predetermined cutting and removal portion 31, and the through holes 30 are formed at predetermined pitches. The removed portion 31 is sucked by the downstream suction device 10 as will be described later.

[0026] The cutter roll 2 is disposed at a position circumscribing the anvil roll 1 .

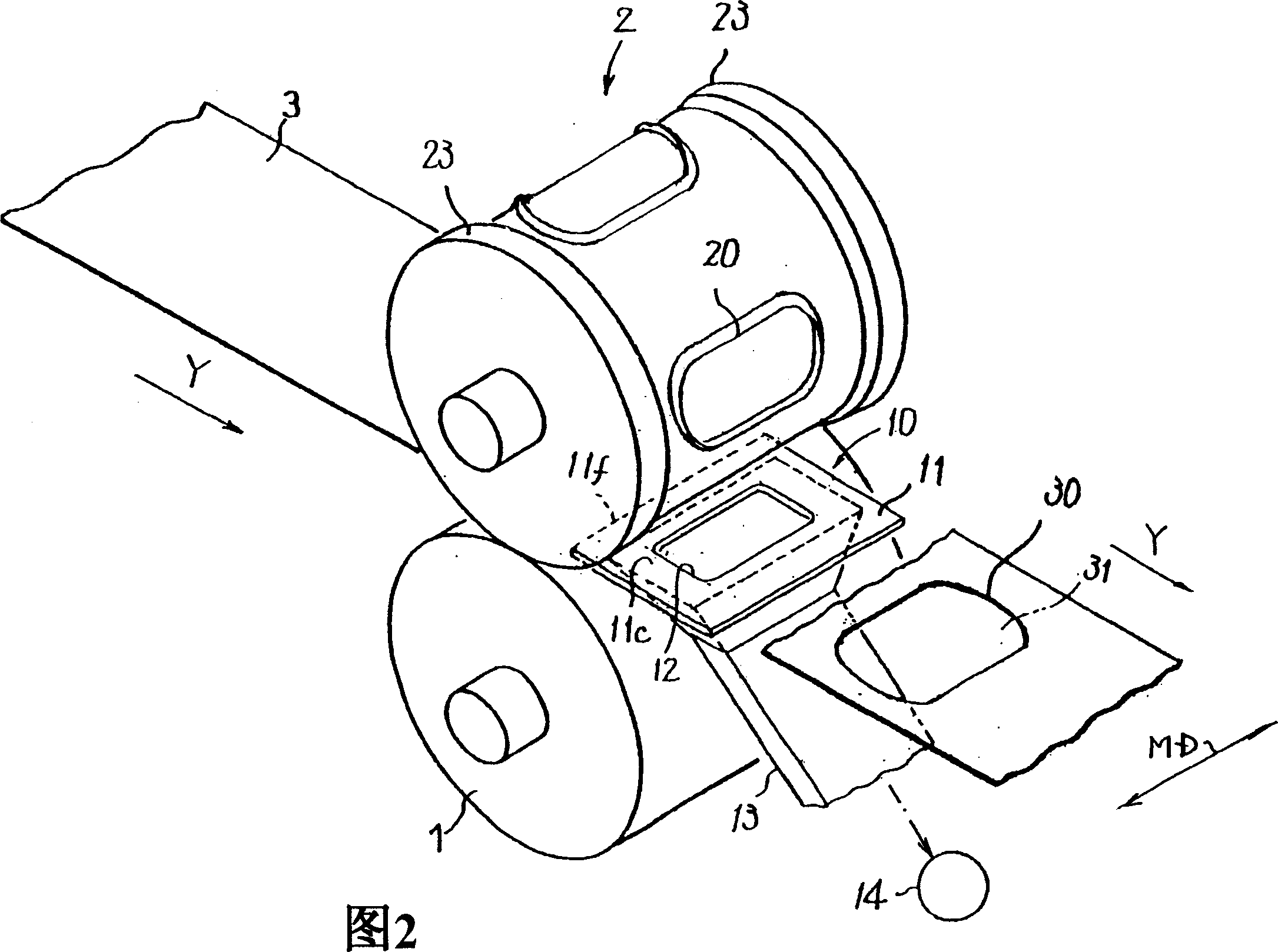

[0027] In addition, in this embodiment, the flange portion 23 having a large diameter formed on the cutter roll 2 shown in FIG. 2 is circumscribed on the anvil roll 1 . The flange portion 23 is for stabilizing the rotation of the cutting roller 2 and protecting the blade 20 .

[0028] As shown in FIG. 2 , the cutting roller 2 has, for example,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com