Food cutting processing machine and steamed stuffed bun making machine

A technology for cutting and processing food, which is applied in food science, dough forming and cutting equipment, dough forming machinery or equipment, etc. It can solve the problems of scattered fillings, low yield and processing efficiency, and inability to wrap fillings, etc., to achieve Smooth cutting action, high cutting efficiency and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

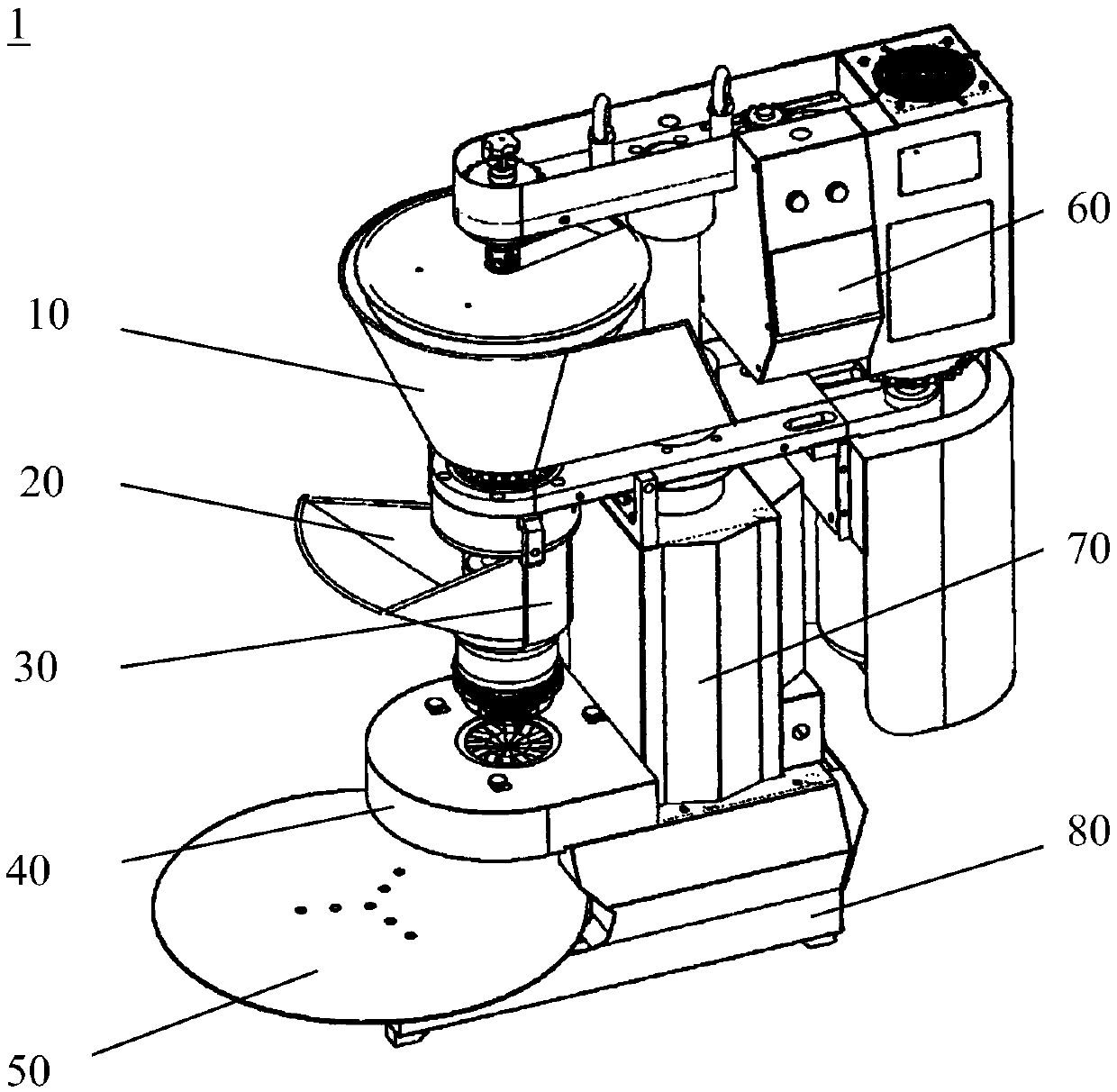

[0028] figure 1 It is a perspective view of the food processing machine which concerns on one Embodiment of this invention. Such as figure 1 As shown, the food processing machine 1 includes a stuffing supply part 10 for dropping in stuffing, a wet noodle input part 20 for putting in wet noodles, a wrapping part 30 for making wet noodles wrapped around the stuffing, The forming part 40 for cutting and forming the buns, the tray part 50 for receiving the formed buns, the control part 60 for controlling the work of the above-mentioned various parts, and the driving mechanism 70 for driving the work of the above-mentioned various parts under the control of the control part 60, and There is a base portion 80 on which each of the above-mentioned parts is carried.

[0029] All parts of the food processing machine 1 work together to make food such as buns. Its overall compactness, high processing efficiency, high yield. Each part is described in detail below.

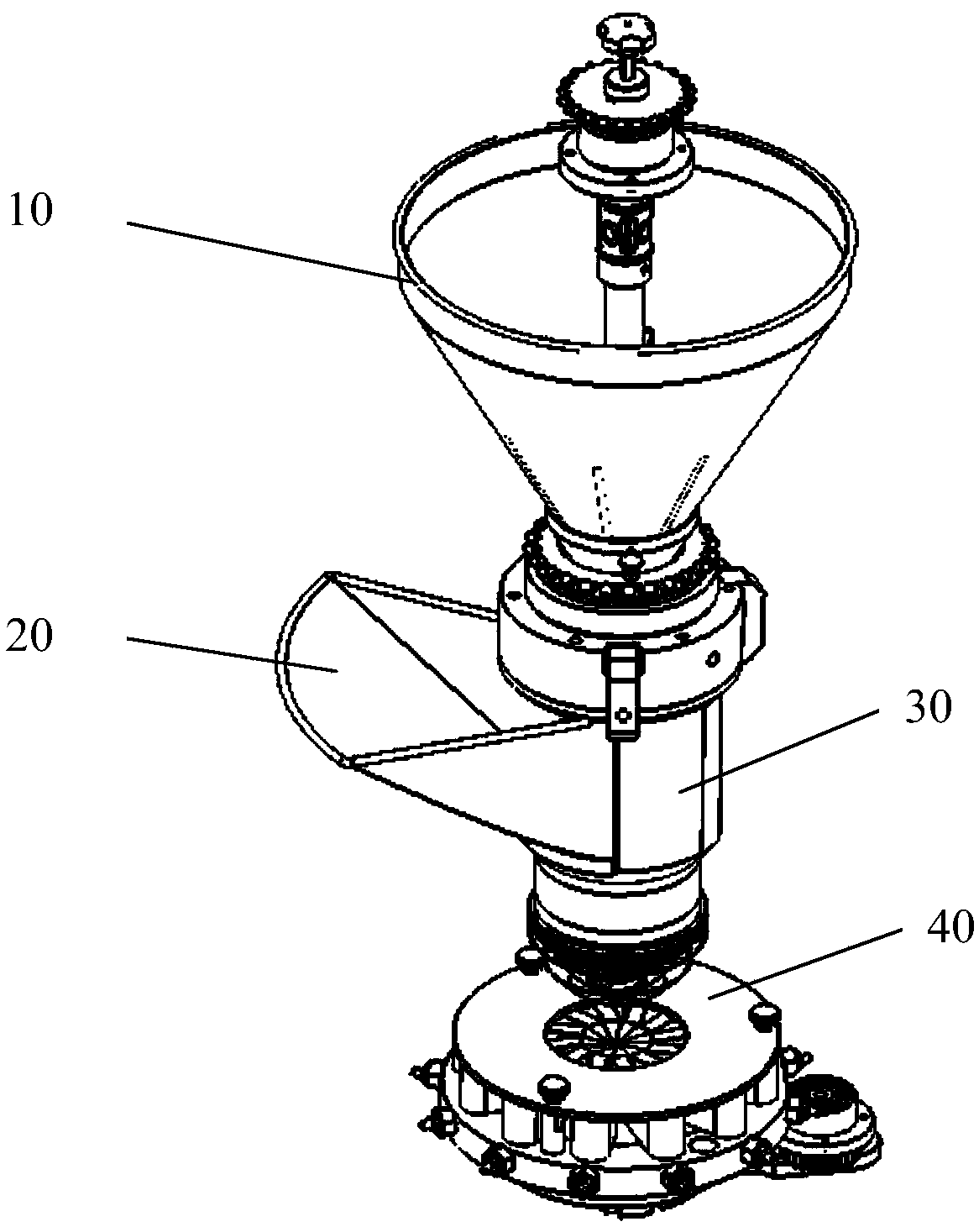

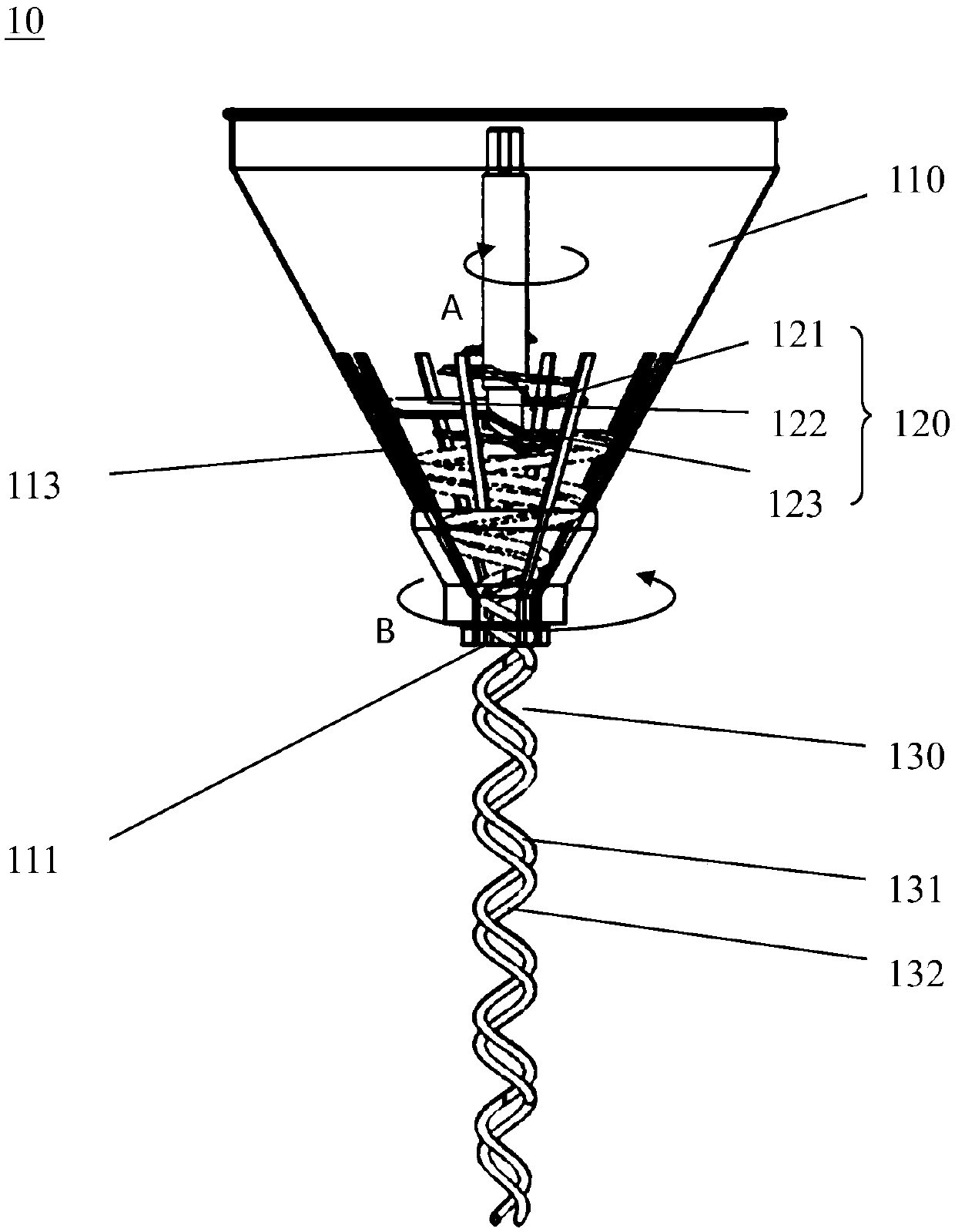

[0030] figure 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com