Wafer processing device and wafer processing method

A wafer processing and wafer technology, which is applied in the field of wafer processing apparatus and wafer processing, can solve the problems of reduced processing efficiency, inability to cut accurately, and entrapped air bubbles, etc., and achieve the effects of improving processing efficiency and simplifying temperature control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] Embodiments of the present invention will be described below with reference to the drawings.

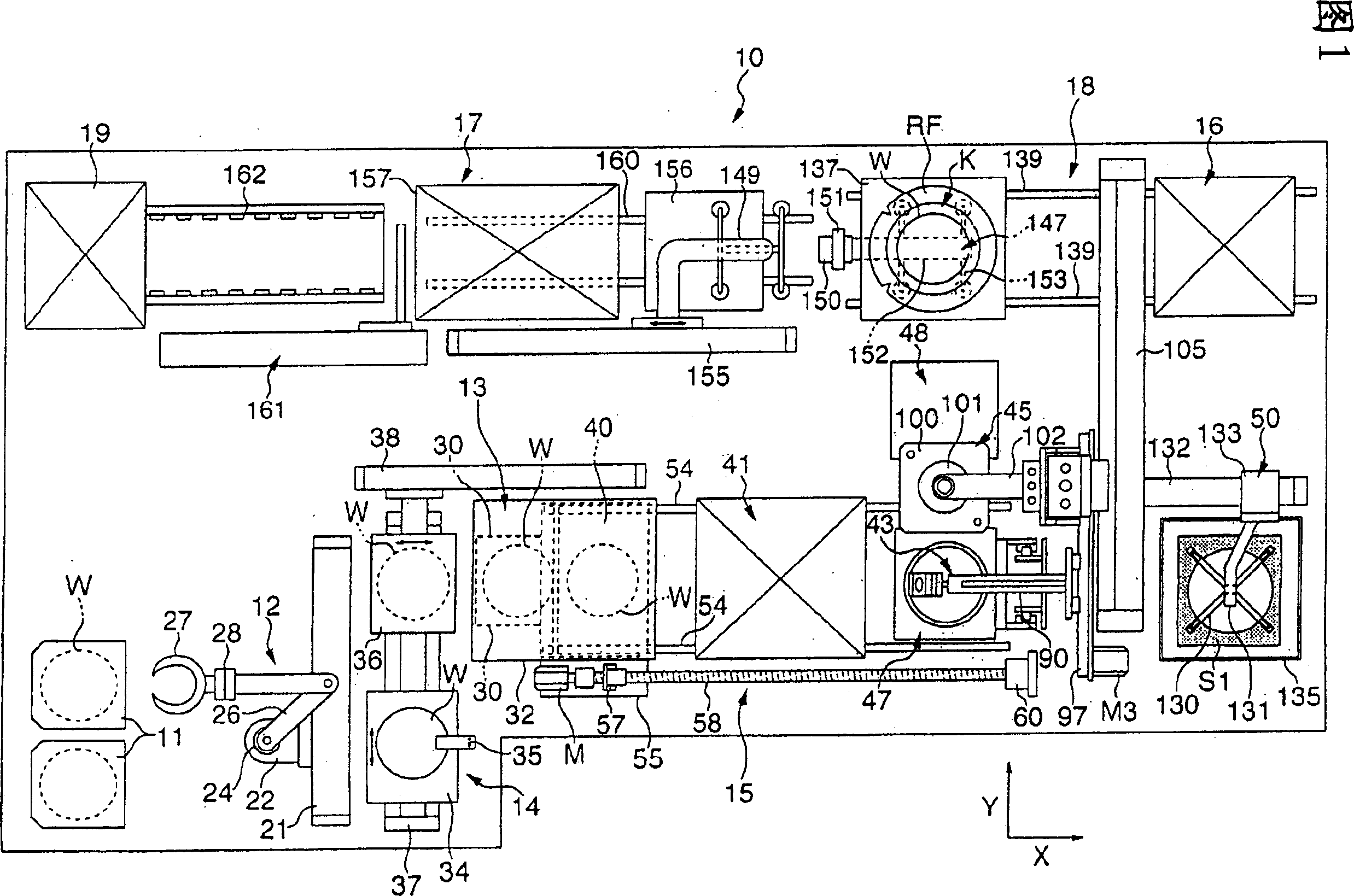

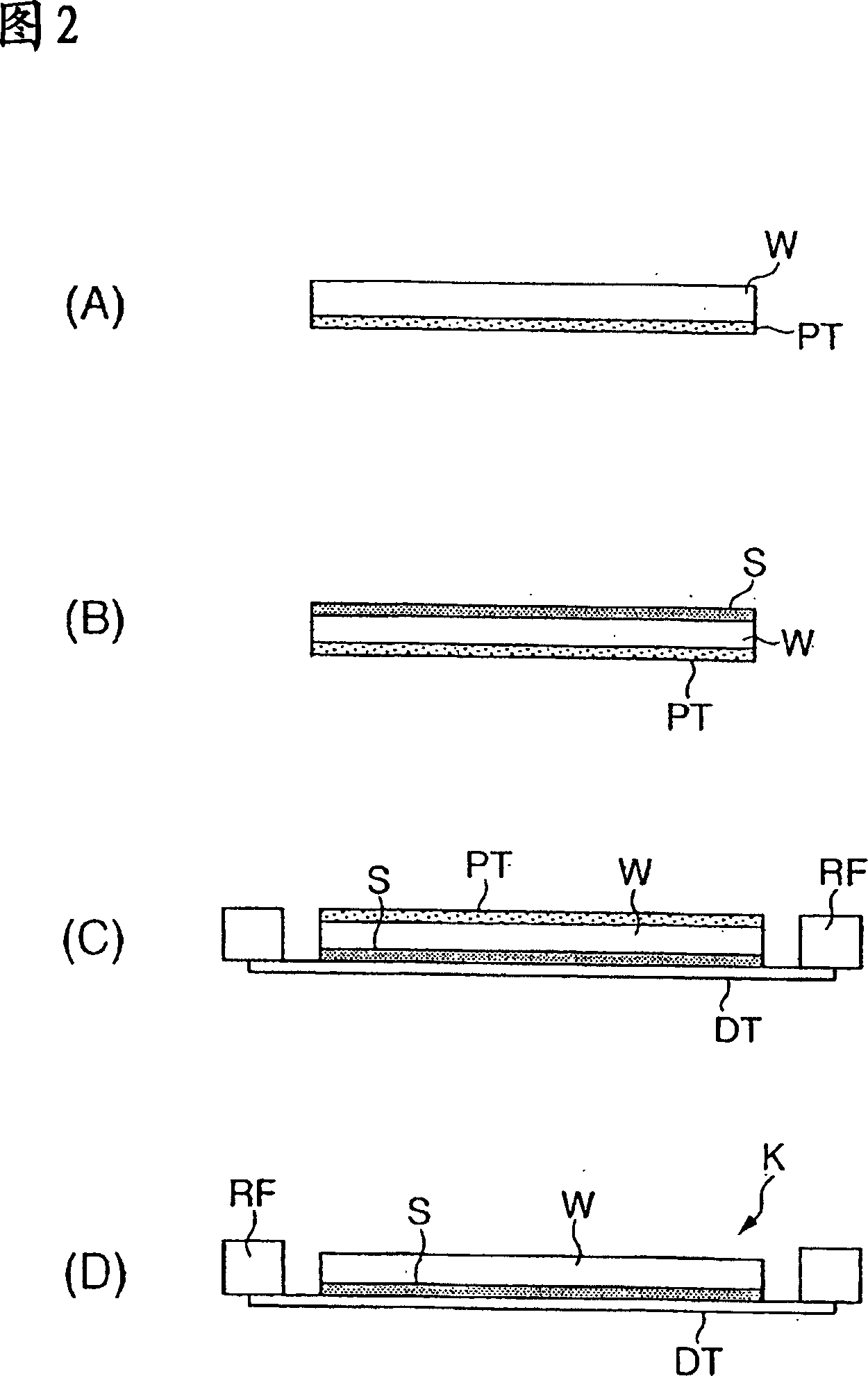

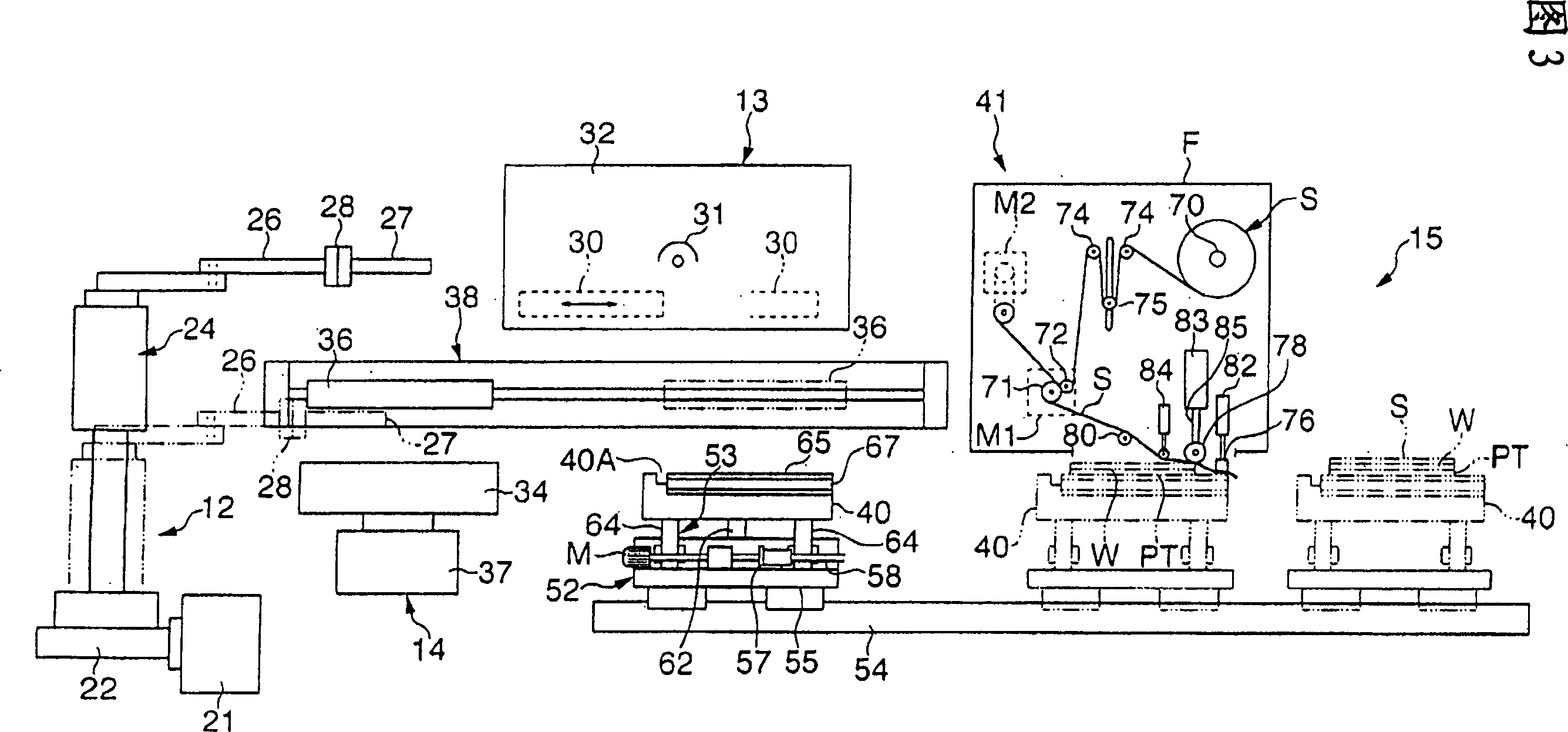

[0075] FIG. 1 is a plan view of a wafer processing apparatus according to this embodiment, and FIG. 2 is a schematic cross-sectional view illustrating wafer processing steps in chronological order. In these figures, the wafer processing apparatus 10 is constituted as an apparatus that performs a series of processes. The series of processes is aimed at a wafer W on which a UV-curable protective tape PT is attached to the surface constituting the circuit surface (see FIG. 2 ). ), after adhering a heat-sensitive adhesive sheet S for die bonding (hereinafter referred to as "adhesive sheet S" to the back surface of the wafer W, mount it on the ring frame RF via a dicing tape (Daishing Tape) DT Wafer W.

[0076] As shown in FIG. 1, the wafer processing apparatus 10 includes a cassette 11 for accommodating wafers W, a robot 12 for sucking and holding wafers W taken out of the casset...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com