Process for manufacturing linen-chenille yarn

A technology of chenille yarn and production process, applied in the directions of yarn, textile and papermaking, fiber processing, etc., can solve the problems of not reflecting the style of chenille yarn, hard feeling of flax yarn, affecting spinning efficiency, etc. To achieve the effect of good spinnability, soft hand feeling and good hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

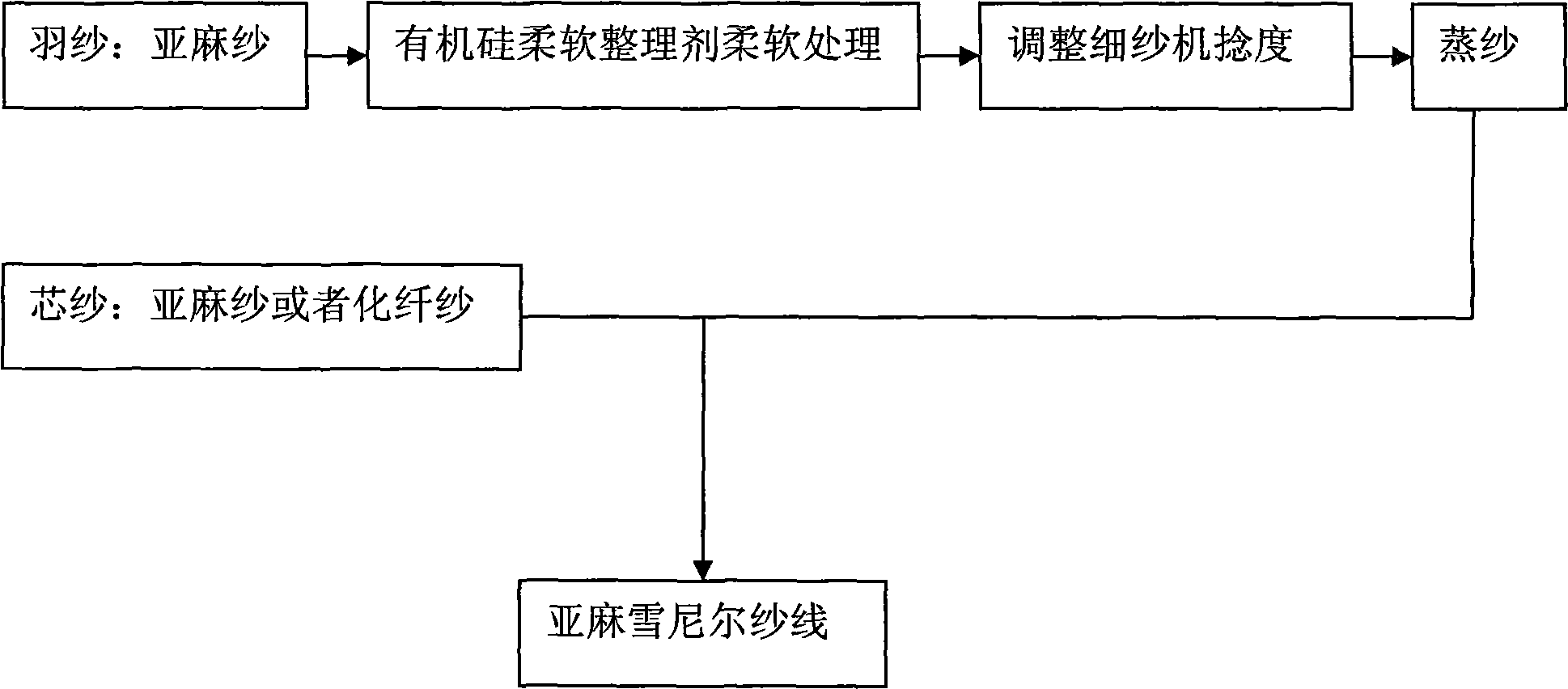

[0012] see figure 1 After the 1.75Nm flax roving is blanched by the conventional flax scouring and bleaching process, the silicone softening agent MEGASOFT LUX is added to soften the blanched flax roving, and a softener with a mass of 4-5% of the blanched flax roving is added, Adjust the pH value to 5-6, and keep warm for 20 minutes at a temperature of 45°C; then, adjust the twist of the flax wet-spinning frame to 420 twists / meter, spin 21Nm flax spun yarn, and steam the yarn after drying and winding. The yarn temperature is 65° C., the heating time from the initial temperature to 65° C. is 1 hour, and then kept at 65° C. for 10 minutes, thereby completing the treatment of the feather yarn. Then adopt 24Nm linen yarn as the core yarn, spin 100% linen chenille yarn on the chenille spinning machine, this technique is identical with conventional chenille yarn spinning process. The flax chenille yarn produced by the manufacturing process of the invention has uniform dryness, good...

Embodiment 2

[0014] see figure 1 After the 1.75Nm flax roving is blanched by the conventional flax scouring and bleaching process, the silicone softening agent MEGASOFT LUX is added to soften the blanched flax roving, and a softener with a mass of 4-5% of the blanched flax roving is added, Adjust the pH value to 5-6, and keep warm for 20 minutes at a temperature of 45°C; then, adjust the twist of the flax wet-spinning spinning machine to 300 twists / m, spin 21Nm flax yarn, and steam the yarn after drying and winding. The temperature is 65° C., the heating time from the initial temperature to 65° C. is 1 hour, and then kept at 65° C. for 10 minutes, thereby completing the treatment of the feather yarn. Then adopt 24Nm polyester chemical fiber yarn as core yarn, spin flax as the flax chenille yarn of feather yarn on chenille spinning machine, this technique is identical with conventional chenille yarn spinning technique. The yarn produced by the manufacturing process of the invention has uni...

Embodiment 3

[0016] see figure 1 After the 1.75Nm flax roving is blanched by the conventional flax scouring and bleaching process, the silicone softening agent MEGASOFT LUX is added to soften the blanched flax roving, and a softener with a mass of 4-5% of the blanched flax roving is added, Adjust the pH value to 5-6, and keep warm at 45°C for 20 minutes; then, adjust the twist of the flax wet-spinning spinning machine to 480 twists / m, spin 21Nm flax yarn, and steam the yarn after drying and winding. The temperature is 65° C., the heating time from the initial temperature to 65° C. is 1 hour, and then kept at 65° C. for 10 minutes, thereby completing the treatment of the feather yarn. Then adopt 24Nm polyester yarn as core yarn, spin flax as the flax chenille yarn of feather yarn on chenille spinning machine, this technique is identical with conventional chenille yarn spinning technique. The yarn produced by the manufacturing process of the invention has uniform dryness, good spinnability ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com