Drying device for sweet potato vermicelli processing

A technology of sweet potato vermicelli and drying device, which is applied in drying, metal processing, and drying solid materials, etc. It can solve the problems of uneven heating of vermicelli and insufficient smoothness, so as to save working time, improve quality and facilitate operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

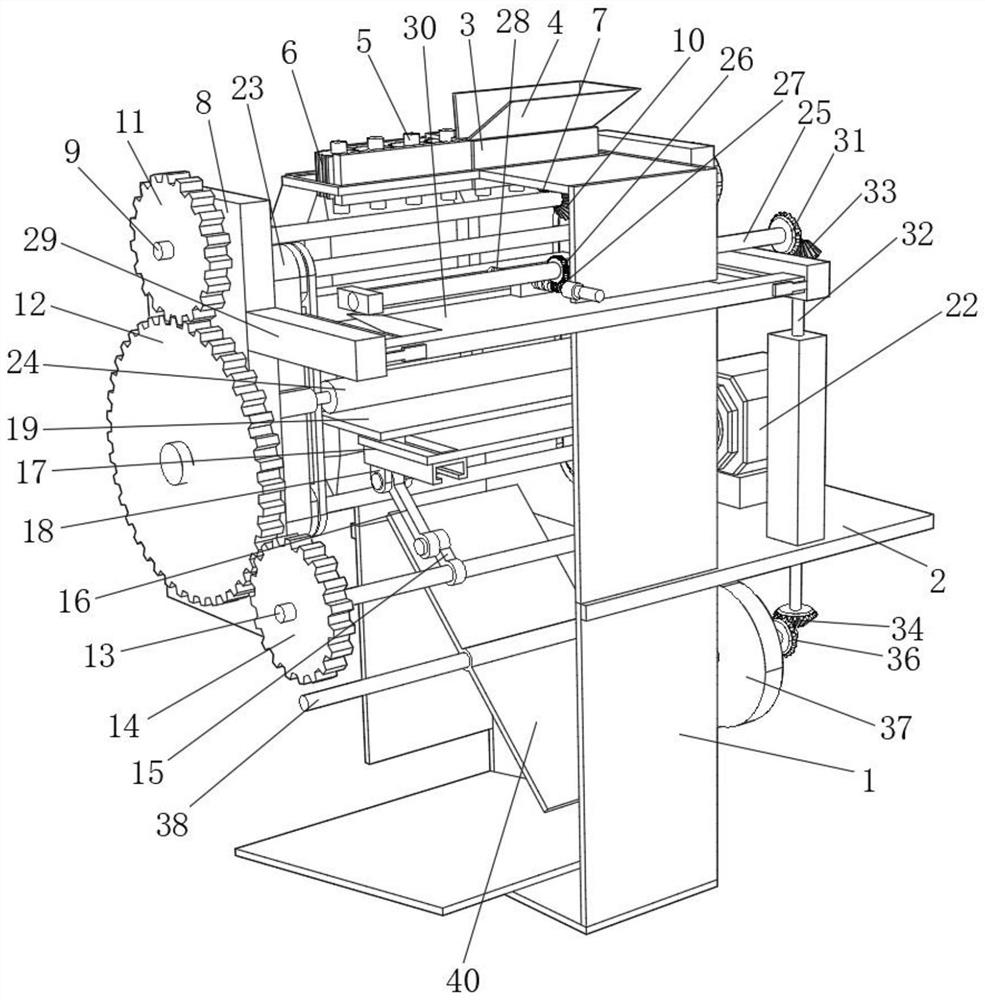

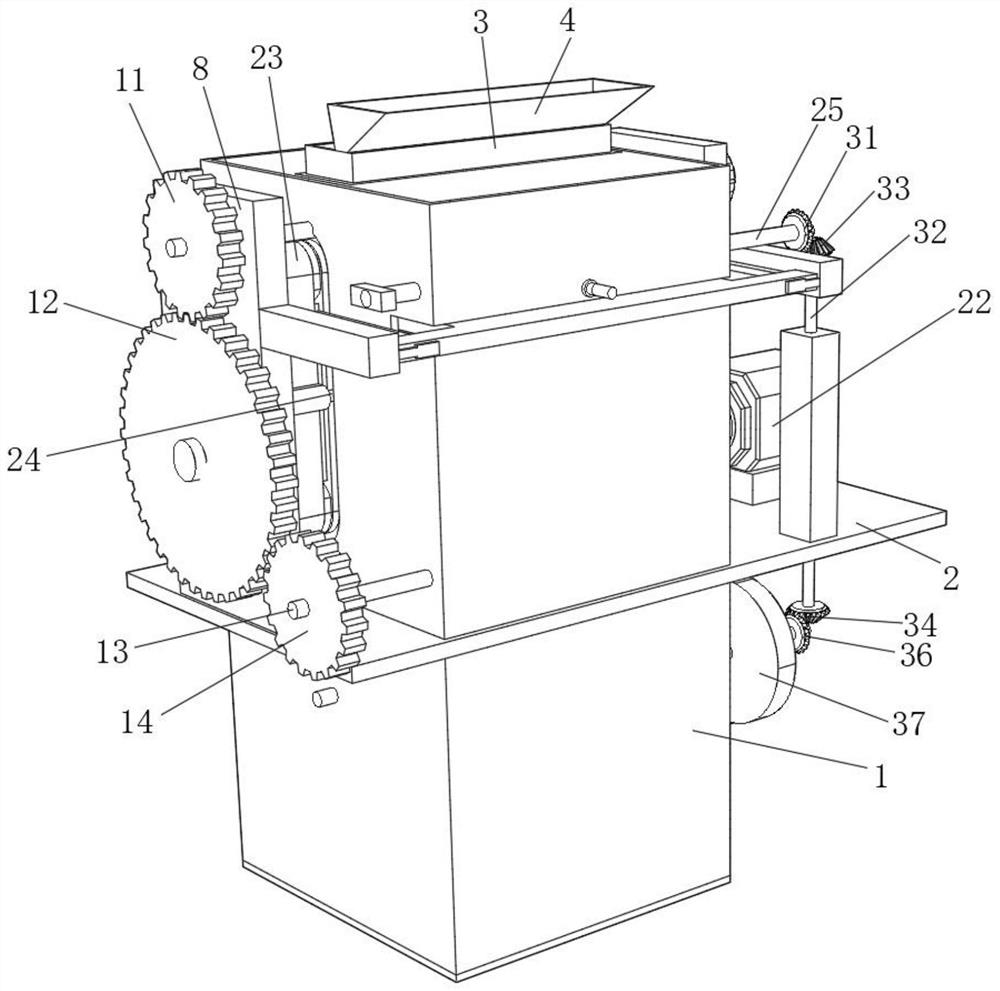

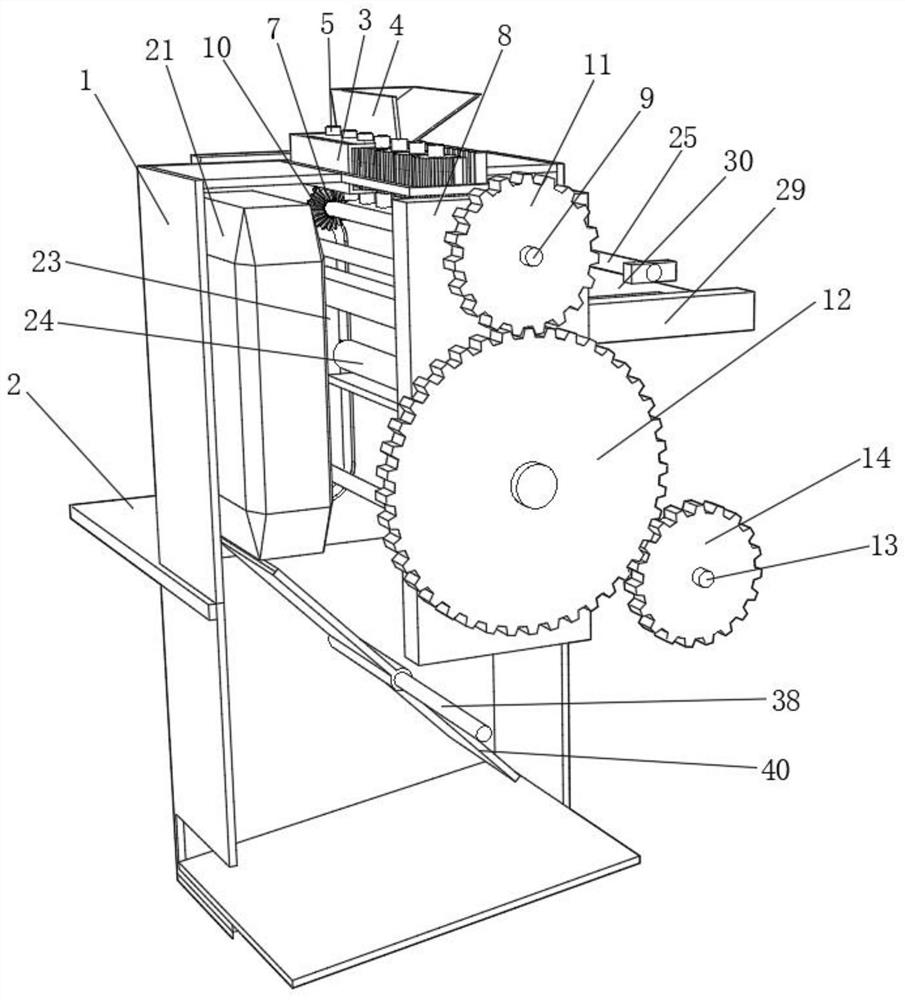

[0029] refer to Figure 1-Figure 4, a drying device for processing sweet potato vermicelli, comprising a cylinder body 1, a support plate 2 is sleeved on the outside of the circumference of the cylinder body 1, a dryer 21 is fixed on one side of the inner wall of the cylinder body 1 by bolts, and both sides of the upper surface of the support plate 2 are Both are fixed with a fixed plate 8 by bolts, the upper surface of the cylinder body 1 is provided with an installation opening, and a support cylinder 3 is fixed by bolts in the installation opening, and a feed pipe 4 is fixed on the upper surface of the support cylinder 3 by bolts, and the support cylinder 3 is equipped with The loose powder mechanism has a movable port on one side of the outer wall of the cylinder body 1, and a movable rod 9 is inserted into the movable port. The setting of the adjusting knob 20 on the movable rod 9 can directly operate the loose powder mechanism and the auxiliary mechanism, improve the con...

Embodiment 2

[0033] refer to Figure 5 , a drying device for sweet potato vermicelli processing, also includes a bottom frame 43, the bottom frame 43 is fixed on the bottom of the cylinder body 1 by bolts, and the drying device can be lifted to a certain height by setting the bottom frame 43 at the bottom of the cylinder body 1, To avoid the influence of the drying device on the heat of the ground, a storage box 44 is provided on one side of the bottom frame 43. At the same time, the vermicelli processed in the discharge port can be directly stored in the storage box 44, which is convenient for packaging the processed vermicelli. 1 The top is fixed with a second motor 41 by bolts, and one end of the output shaft of the second motor 41 is connected to the connecting rod through the second belt 42, and the setting of the second motor 41 and the second belt 42 can be controlled by mechanical force. The interaction between the powder cutting mechanism and the tilting mechanism not only saves m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com