Chip discharging device of button hole of button

A discharge device and keyhole technology, which is applied to sewing tools, textiles and papermaking, and clothes piece conveyors, etc., can solve the problems of poor sewing quality and inability to reliably isolate cloth chips, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The purpose and advantages of the present invention will be described in detail below in conjunction with the accompanying drawings, so as to gain a deep understanding.

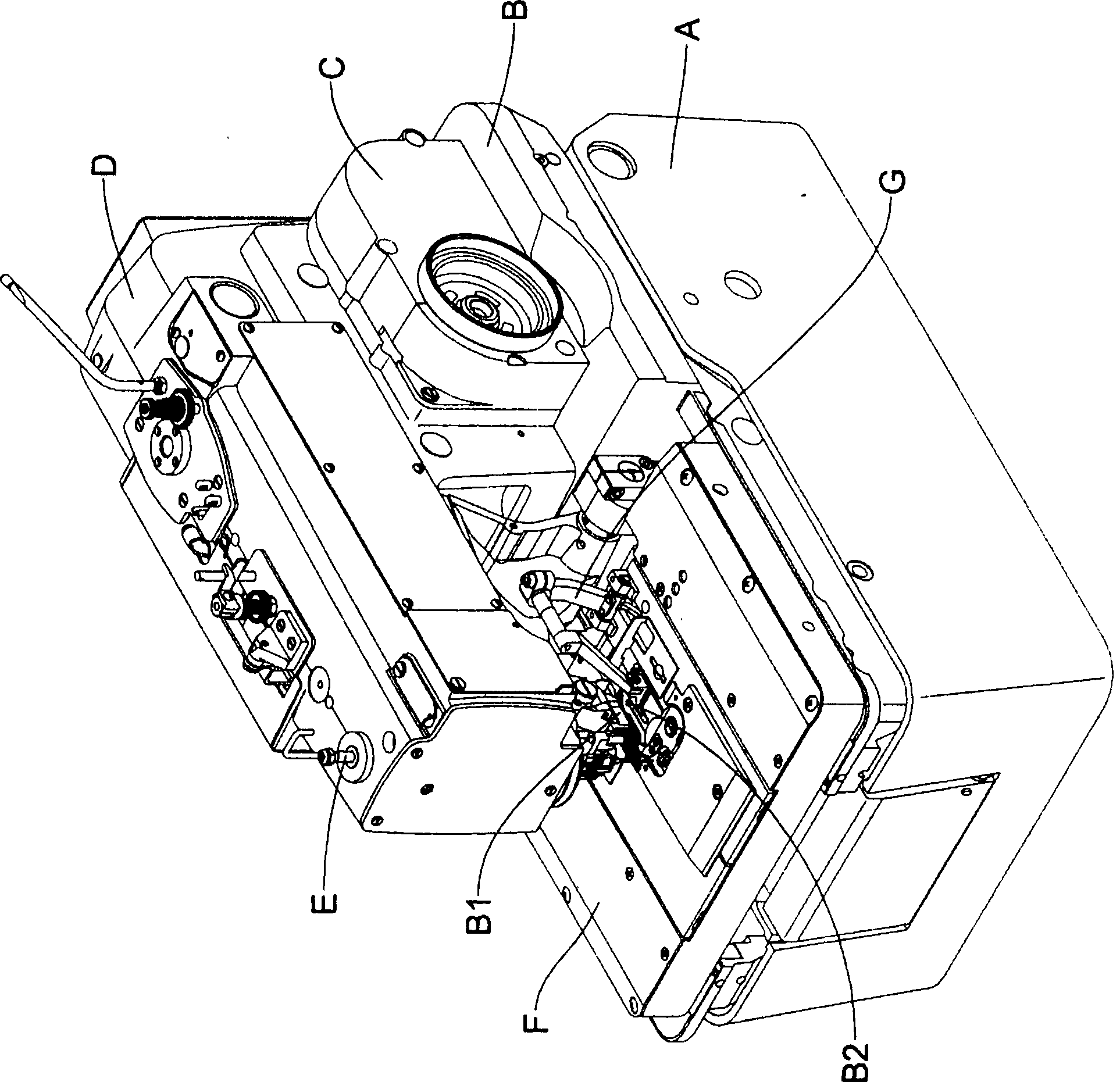

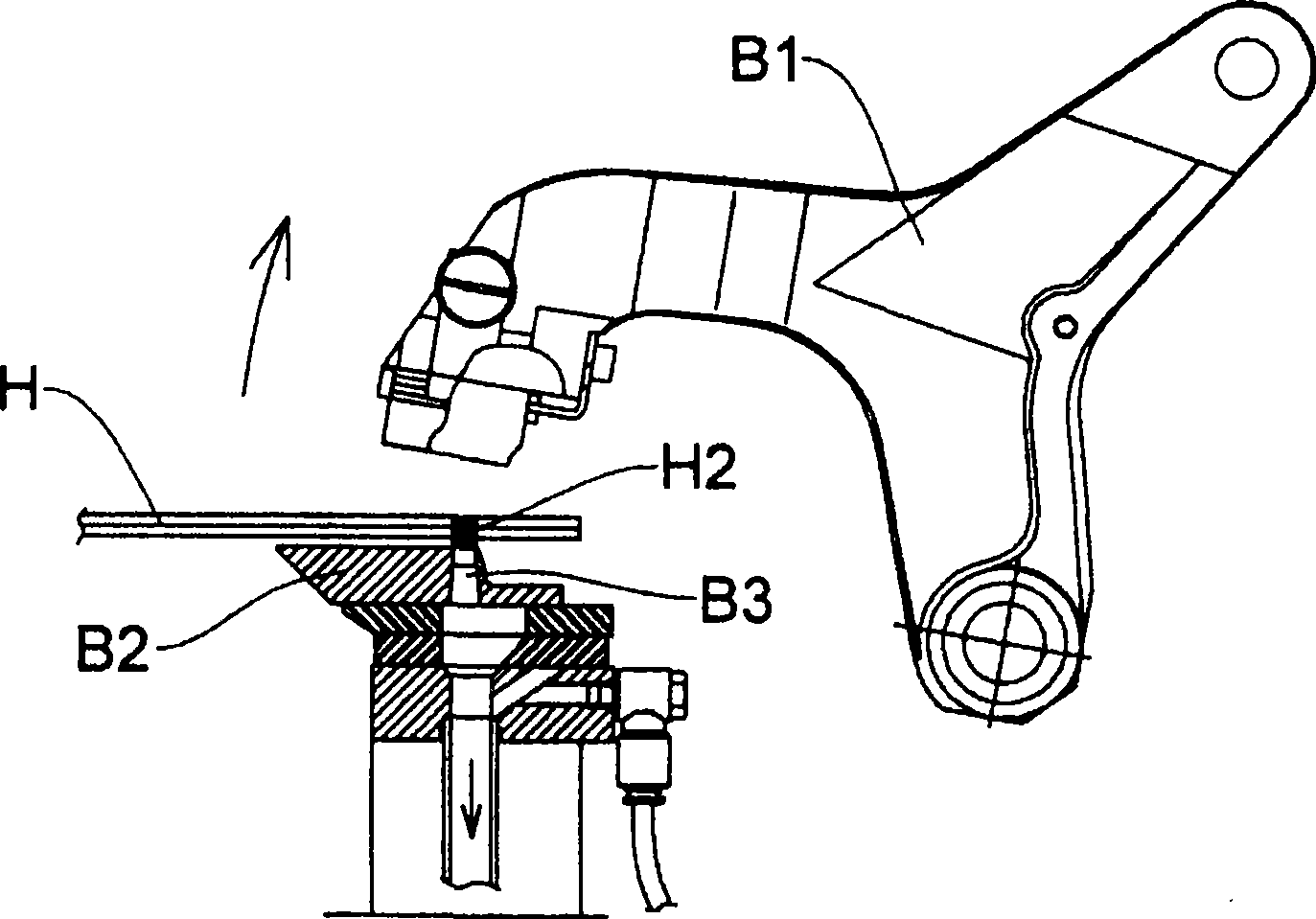

[0046] see Figure 4 Shown is a perspective view of the present invention. The present invention includes a pressing device 1, a tool holder 2 and a cutter 3, the pressing device 1 and the cutter holder 2 are fixed on the bed base B, the cutter 3 is arranged above the cutter holder 2, and is located in the pressing device 1 below the front end. The crimping device 1 includes a rotating shaft 11, and an operating rod 12 whose shaft is arranged on the rotating shaft 11. A clamping screw 13 is used to fix a crimping block 14 at the front end of the operating rod 12. The bottom surface of the crimping block 14 is a flat crimping surface. 140. The operating rod 12 is centered on the rotating shaft 11 and can rotate, so that the press-cut block 14 rotates downward to engage the cutter 3 to cut the cloth. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com