Cutting device and cutting method of pipes

A technology for cutting devices and pipes, which is applied in the direction of pipe shearing devices, shearing devices, and accessories of shearing machines, etc. It can solve the problems that pipes cannot be cut obliquely, burrs are easy to generate, and pipes are easy to generate dust, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The embodiments of the present invention will be described in detail below:

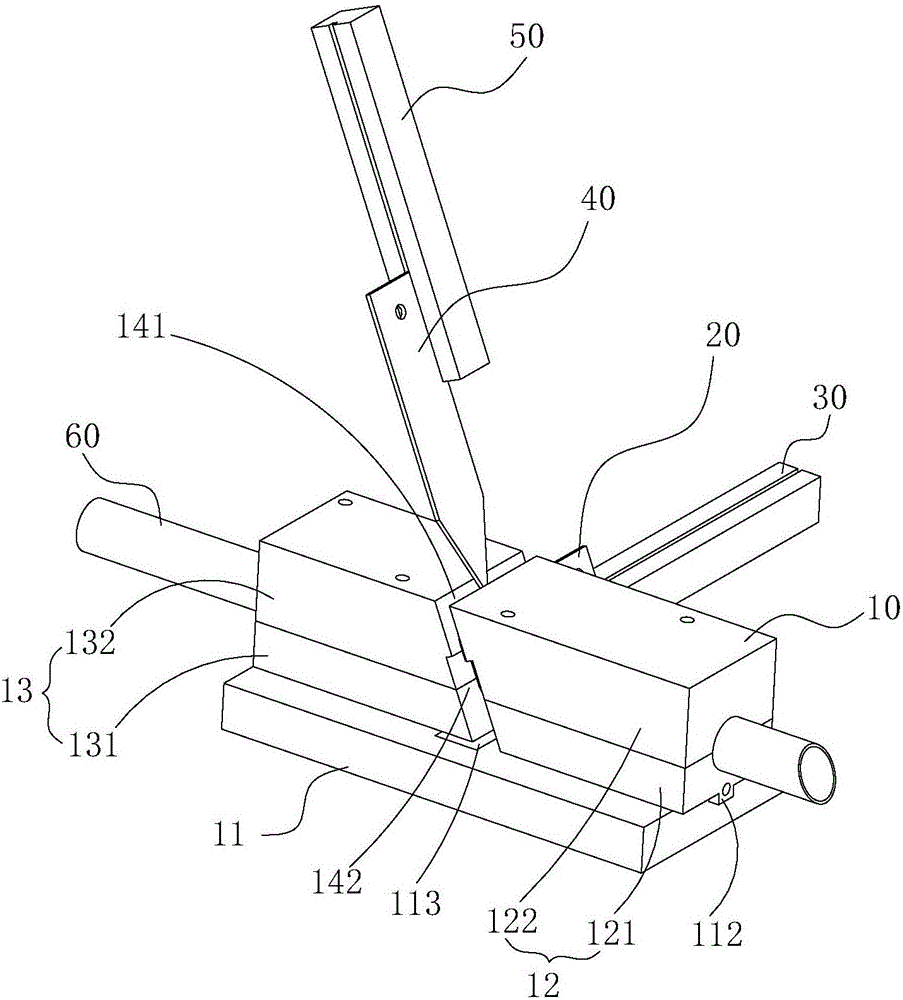

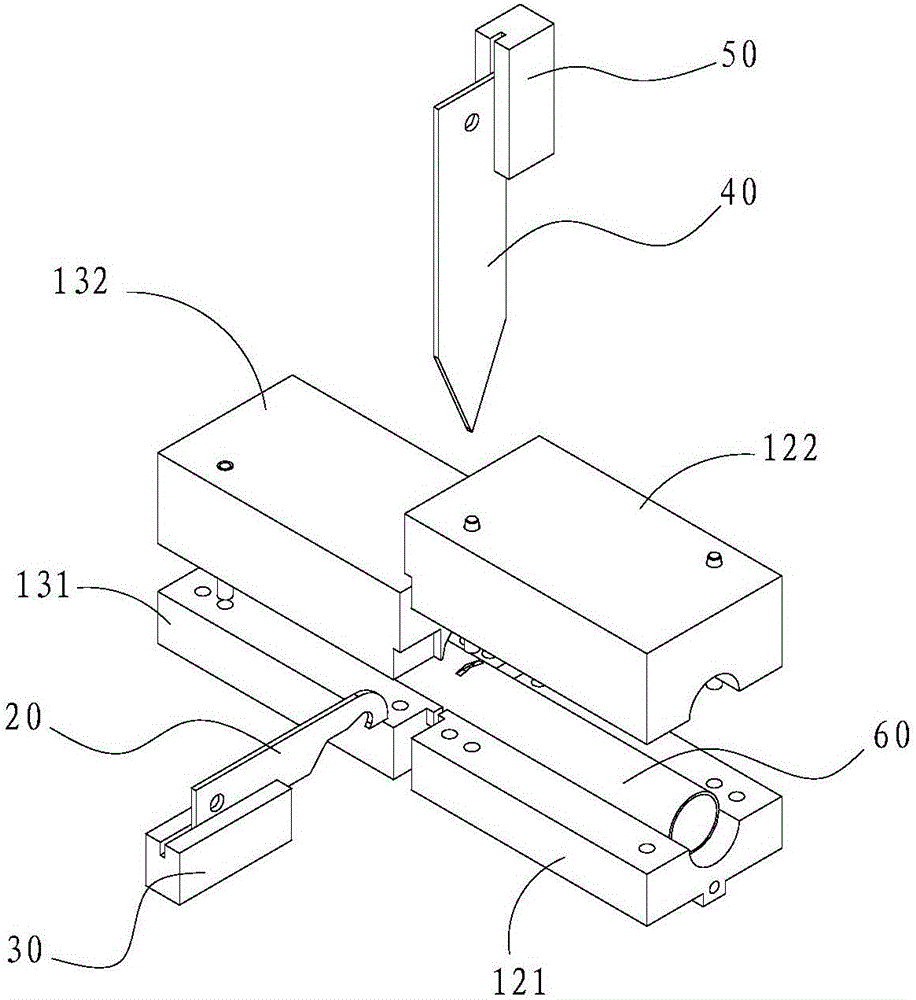

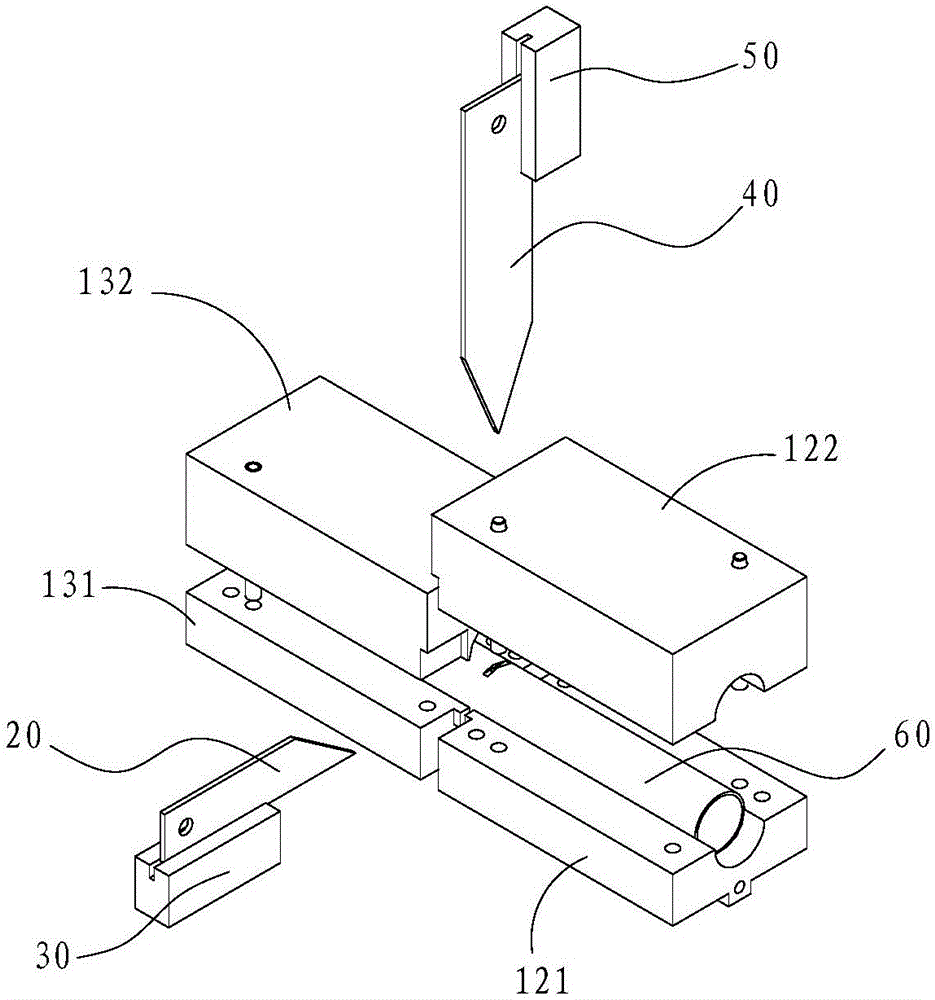

[0032] Such as figure 1 As shown, the pipe cutting device according to the embodiment of the present invention includes a clamping mechanism 10, a first cutting member 20, a first driving member 30, a second cutting member 40, and a second driving member 50.

[0033] The clamping mechanism 10 is used to clamp the pipe 60. The first cutting member 20 is arranged obliquely with respect to the pipe 60. The first driving member 30 is in transmission connection with the first cutting member 20, and the first driving member 30 is used to drive the first cutting member 20 to move back and forth in a first direction to move on the side wall of the pipe 60 Form an incision 61 (such as Figure 5 , 6 Or as shown in 7). Since the first cutting member 20 is inclined relative to the pipe 60, the cut 61 formed on the side wall of the pipe 60 is inclined accordingly.

[0034] The second cutting member 40 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com