Harvester head structure and mustard tuber harvester comprising same

A harvester and machine head technology, applied in the field of mustard harvesters, can solve the problems of low work efficiency, difficult separation, impurities and soil, and broken leaves are easily mixed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

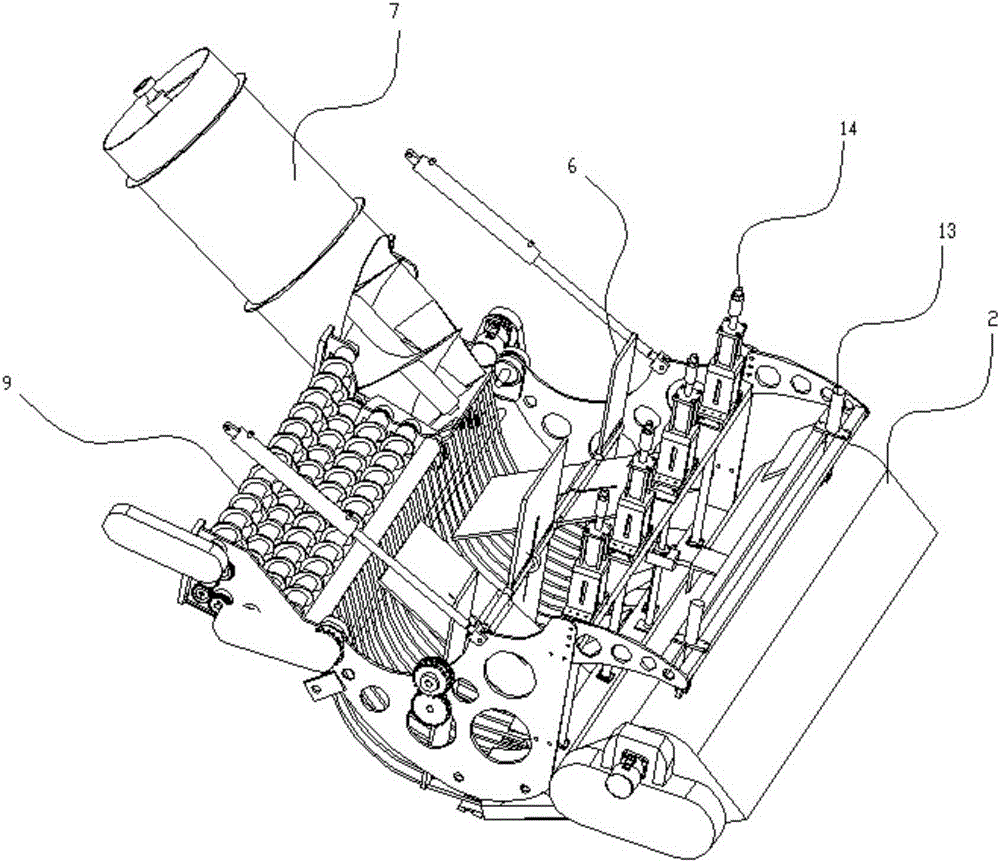

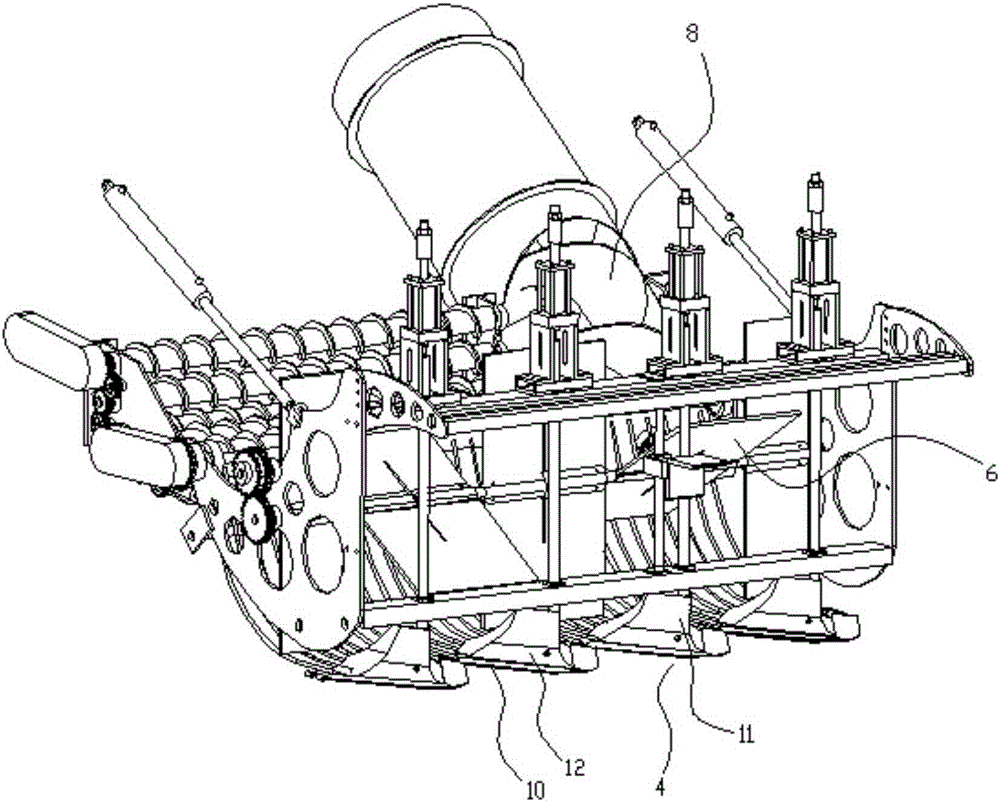

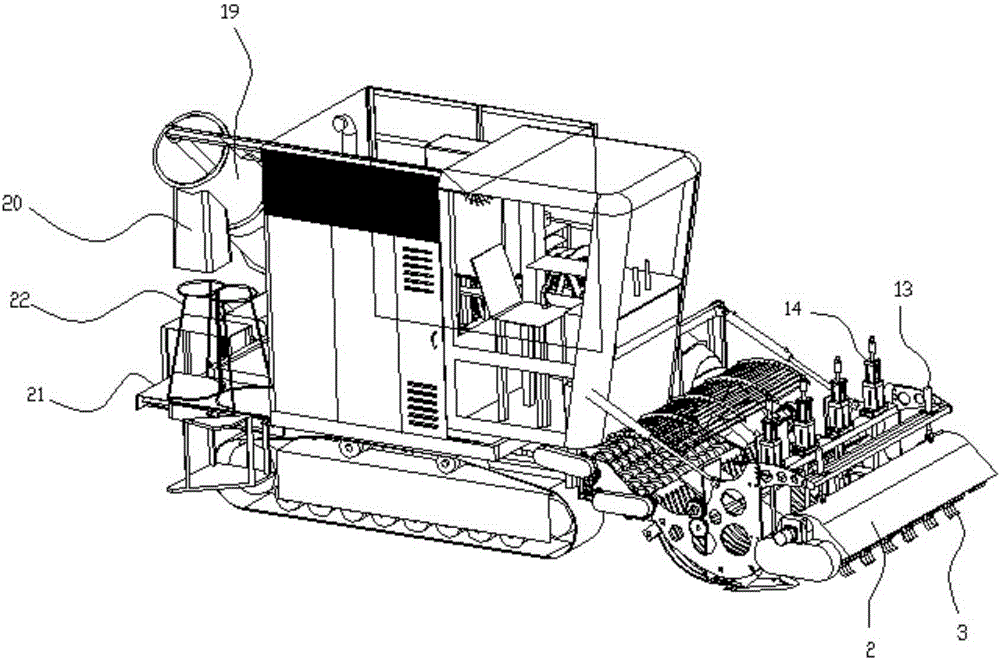

[0023] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 In the shown embodiment, a harvester head structure includes a head frame 1, a leaf beating mechanism, and a shoveling mechanism. The leaf beating mechanism includes a leaf beating cover 2 with an open lower end, which is driven by the power assembly of the harvester. The beating shaft, the beating shaft is in the beating cover and is horizontal, the beating shaft is provided with several beating cutter wheels 3, and the stem shoveling mechanism includes several stem shoveling knives 4, the The head frame described above is provided with a low front end and a high rear end material fence arc plate 5, the leaf beating mechanism is on the front side of the shovel knife, and the front end of the bottom material fence arc plate faces the rear side of the shovel knife. The t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com