Shearing-seepage coupling experiment method of fracture network rock

A technology of crack network and experimental method, which is applied in the direction of applying stable shear force to test the strength of materials, instruments, measuring devices, etc., can solve the problems of slow progress of crack network, etc., and achieve fast engraving speed, small footprint and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

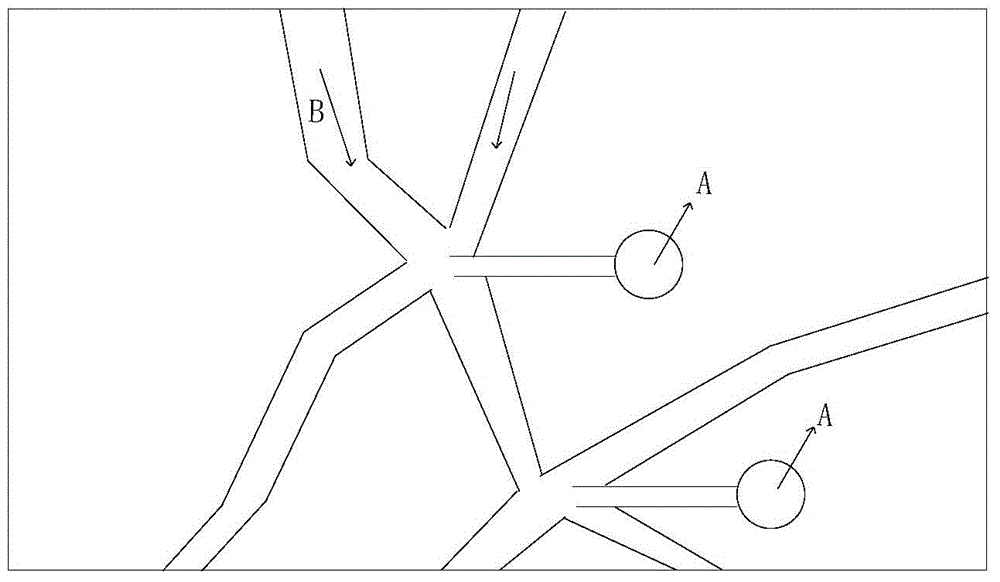

[0028] Fracture network rock shear-seepage coupled experimental method, comprising the following steps:

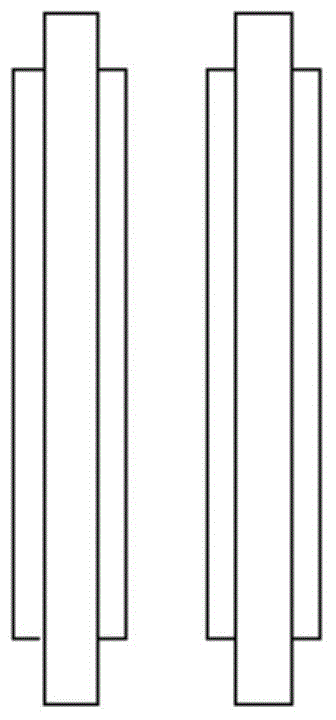

[0029] (1) Select the material and size of the test piece. Select two rectangular bluestone slabs of the same size with a length and width of 10-80cm and a thickness of 0.8-2cm as test pieces.

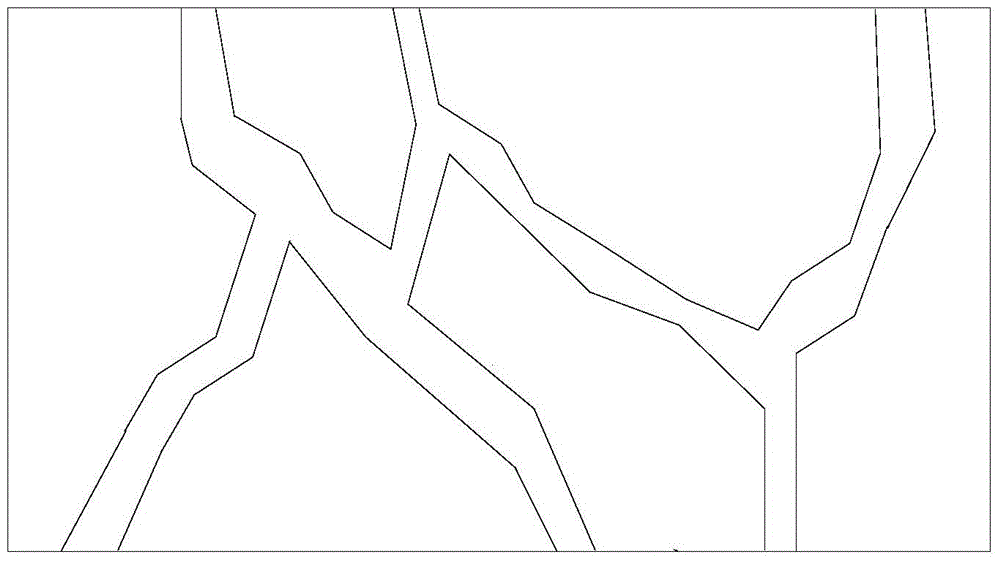

[0030] (2) Sculpture planar fracture network. Put the two bluestone slab test pieces on the engraving machine, randomly generate cracks by the computer, and control the engraving machine to carve the same cracks on the two bluestone slab test pieces, and the width of the cracks forming the crack network is 0.5-3mm.

[0031] (3) Make experimental samples. Add glass to fix on both sides of the bluestone slab test piece, and apply glue between the bluestone slab test piece and the glass. The purpose of this is to prevent the water from seeping out during water injection on the one hand; on the other hand, to prevent the cut rock and soil from breaking and to play a role of reinforc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com