Direct shear testing device of saturated rock soil samples

A test device and direct shearing technology, applied in the direction of testing material strength by applying stable shear force, testing material strength by applying repetitive force/pulsation force, etc., can solve the problem of large sample size and unaccurate control of saturation of the sample degree, can not be well applied and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

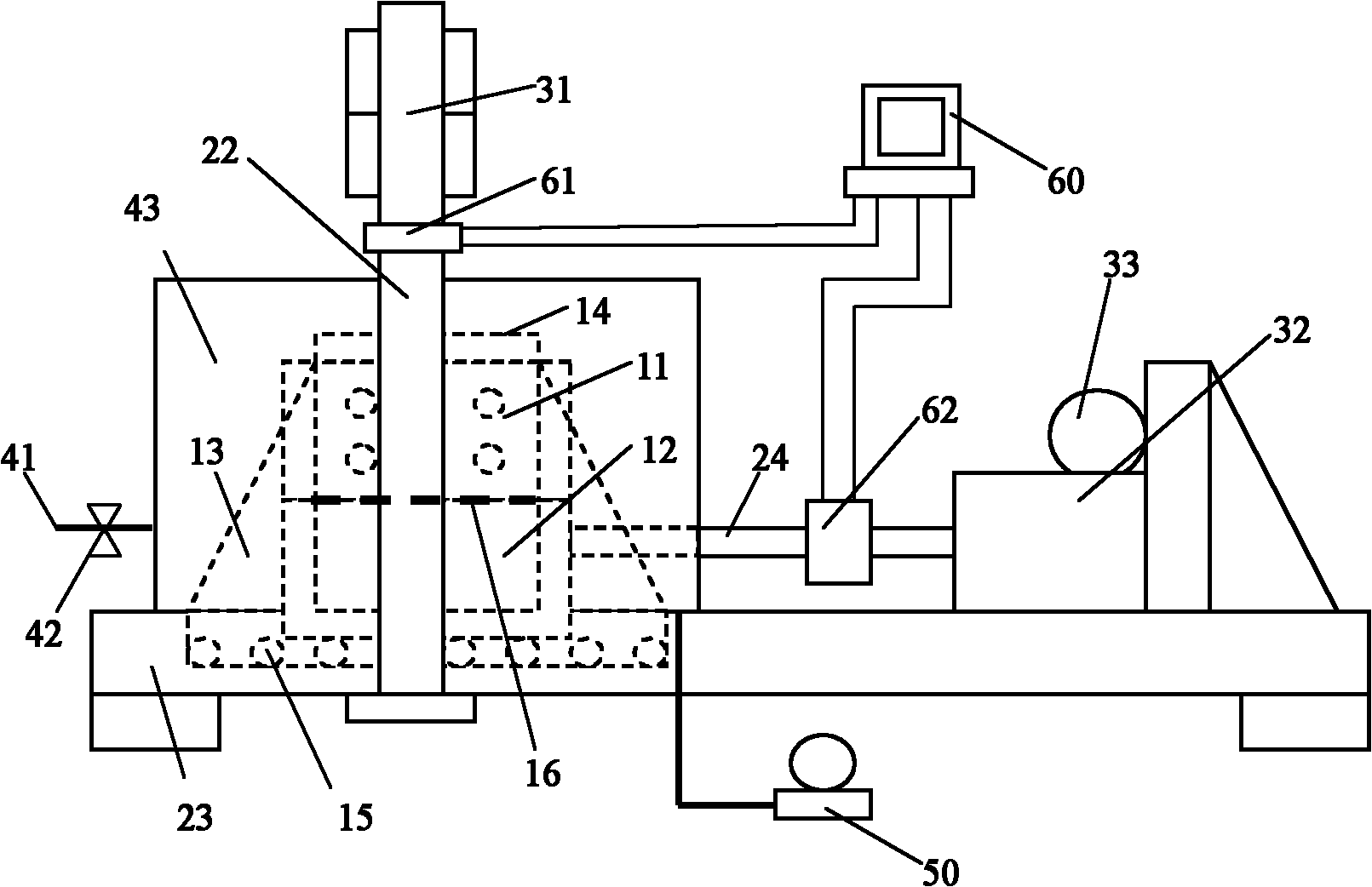

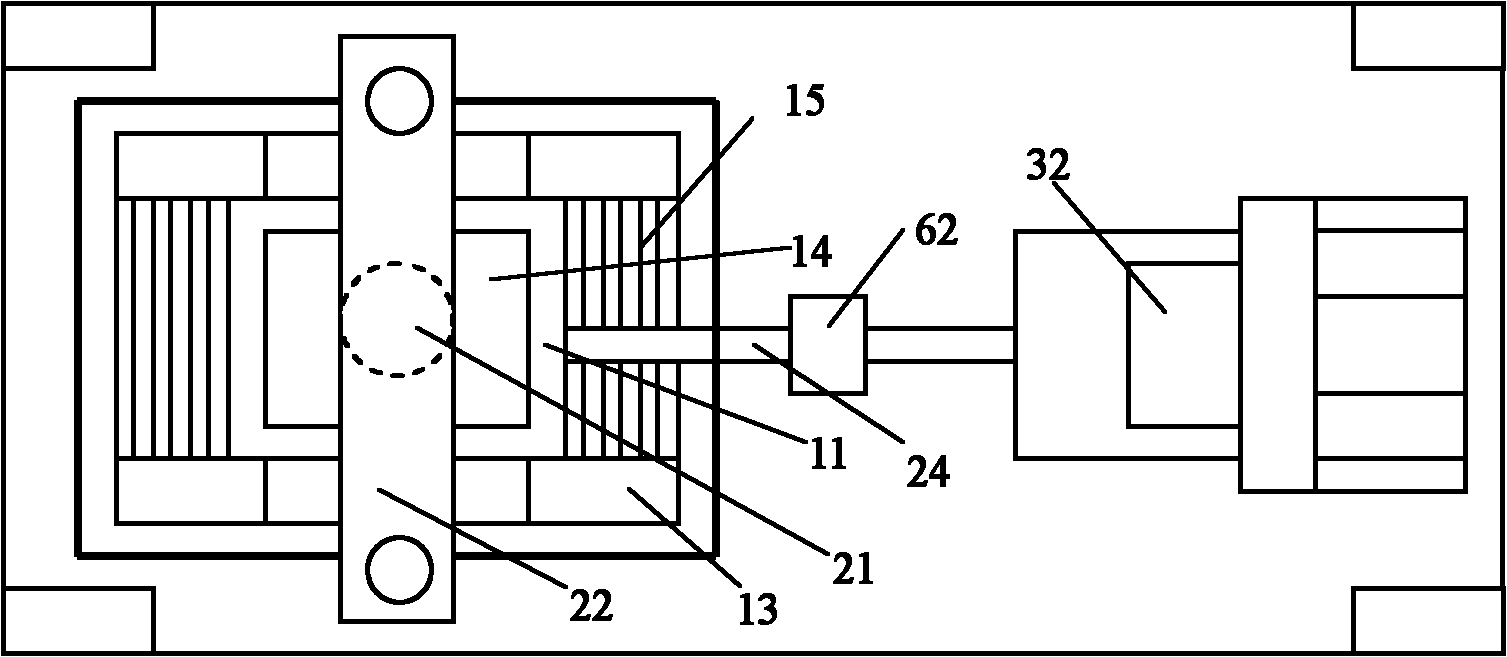

[0038] Below in conjunction with accompanying drawing and embodiment describe in detail:

[0039] 1. Overall

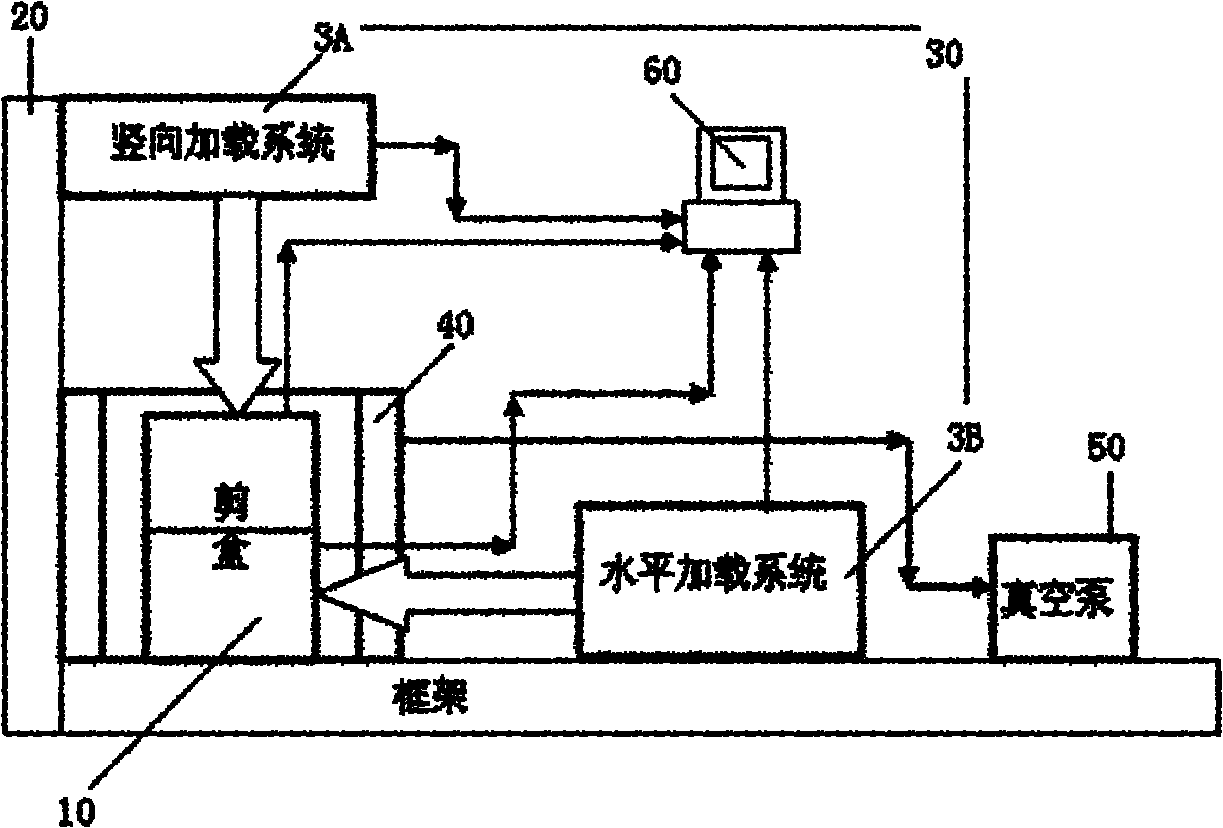

[0040] like figure 1 , the device includes a sample shear box 10, a frame 20, a loading system 30, a saturation system 40, a vacuum pump 50 and a data acquisition system 60;

[0041] Its connection relationship is:

[0042] The sample shear box 10, the loading system 30, the saturation system 40, the vacuum pump 50 and the data acquisition system 60 are all fixed on the frame 20 to form a whole;

[0043] The sample shear box 10 is placed in the water tank 43 of the saturation system 40 to ensure that the sample can be completely saturated;

[0044] The loading system 30 includes a vertical loading system 3A and a lateral loading system 3B, which are respectively connected to the scissor box 10 to realize vertical loading and lateral loading of the sample scissor box 10;

[0045] The vacuum pump 50 is connected with the saturation system 40 to vacuumize the closed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com