Rock direct shear experiment test piece, test piece clamp and shear testing method thereof

A shear test and specimen technology, applied in the direction of applying stable shear force to test material strength, measuring devices, instruments, etc., can solve the unfavorable transversely isotropic rock shear strength test and the inability to obtain rock shear stress The problem of relationship with shear displacement and high cost can achieve the effect of facilitating mass production, processing and manufacturing, solving uneven stress distribution and uniform compressive stress distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

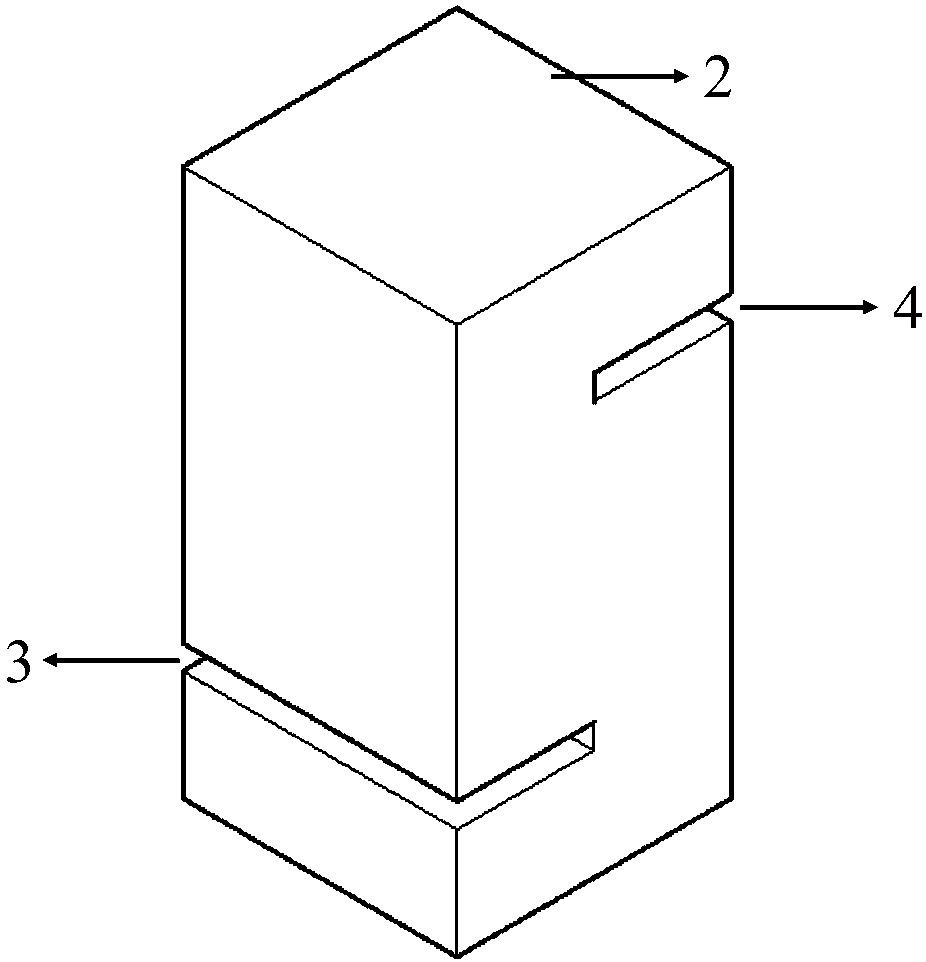

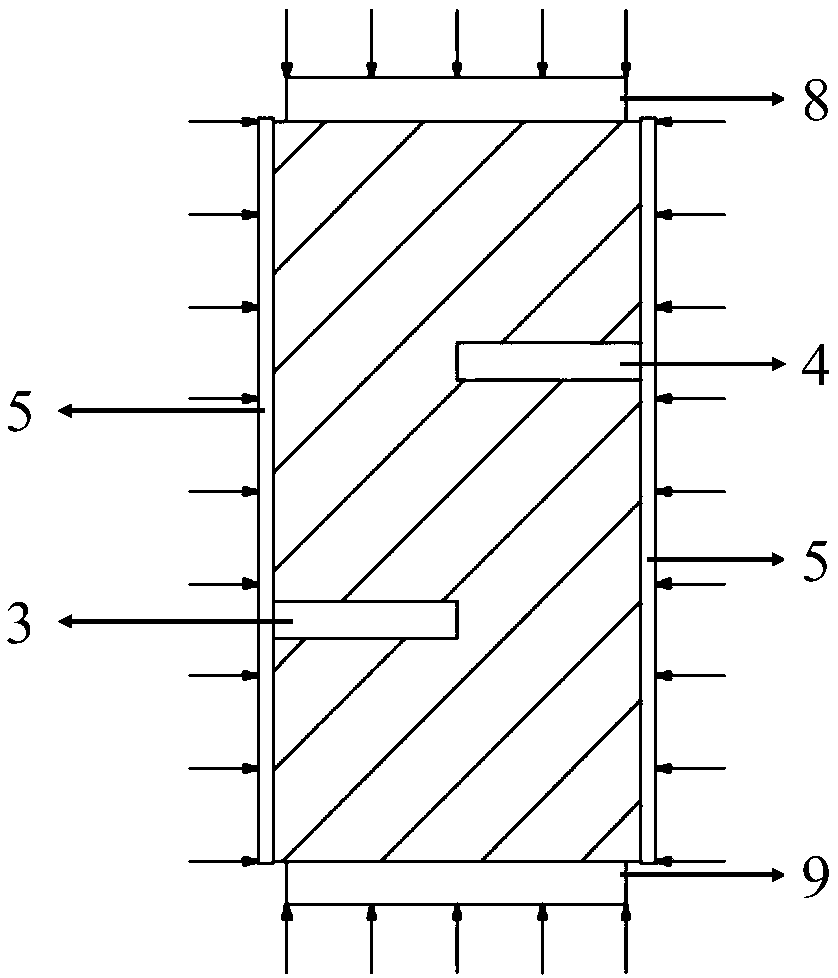

[0049] A rock shear test method comprising the following steps:

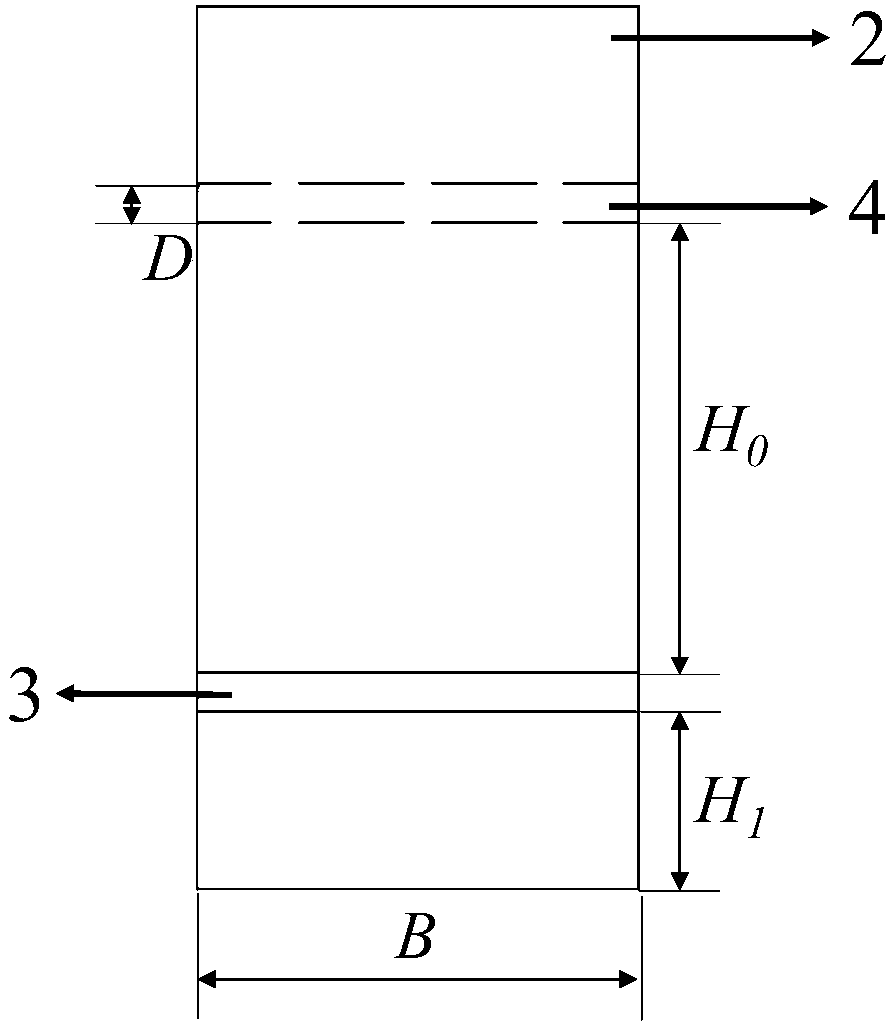

[0050] (1) Select the marble core of the Diversion Tunnel of Jinping Underground Laboratory with a buried depth of 2400m, and apply for the aforementioned rock direct shear test specimen for processing cost. On the left side of the test piece, 34mm from the top, set a 1mm-thick cutting groove through the inside of the test piece. The groove direction is parallel to the top surface, and the length is 25mm. A groove with a thickness of 1mm makes the entire specimen a centrally symmetrical figure, then the distance between two grooves H 0 =80mm.

[0051] (2) Select a solid steel direct shear fixture with a diameter of 120mm in diameter, a hexagonal groove in the middle of 50mm, and a height of 148mm. Place polytetrafluoroethylene drag-reducing sheets on the left and right sides of the specimen, and use 502 glue on the front and rear sides. Strain gauges are attached and further fixed with resin. Then put the tes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com