Interlayer direct shear testing device and testing method

A shear test, a direct technology, applied in the direction of applying a stable shear force to test the strength of materials, etc., can solve the problems of unreal interface parameters, core sample disturbance, and reduce the accuracy of test results, etc., to improve convenience and improve The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

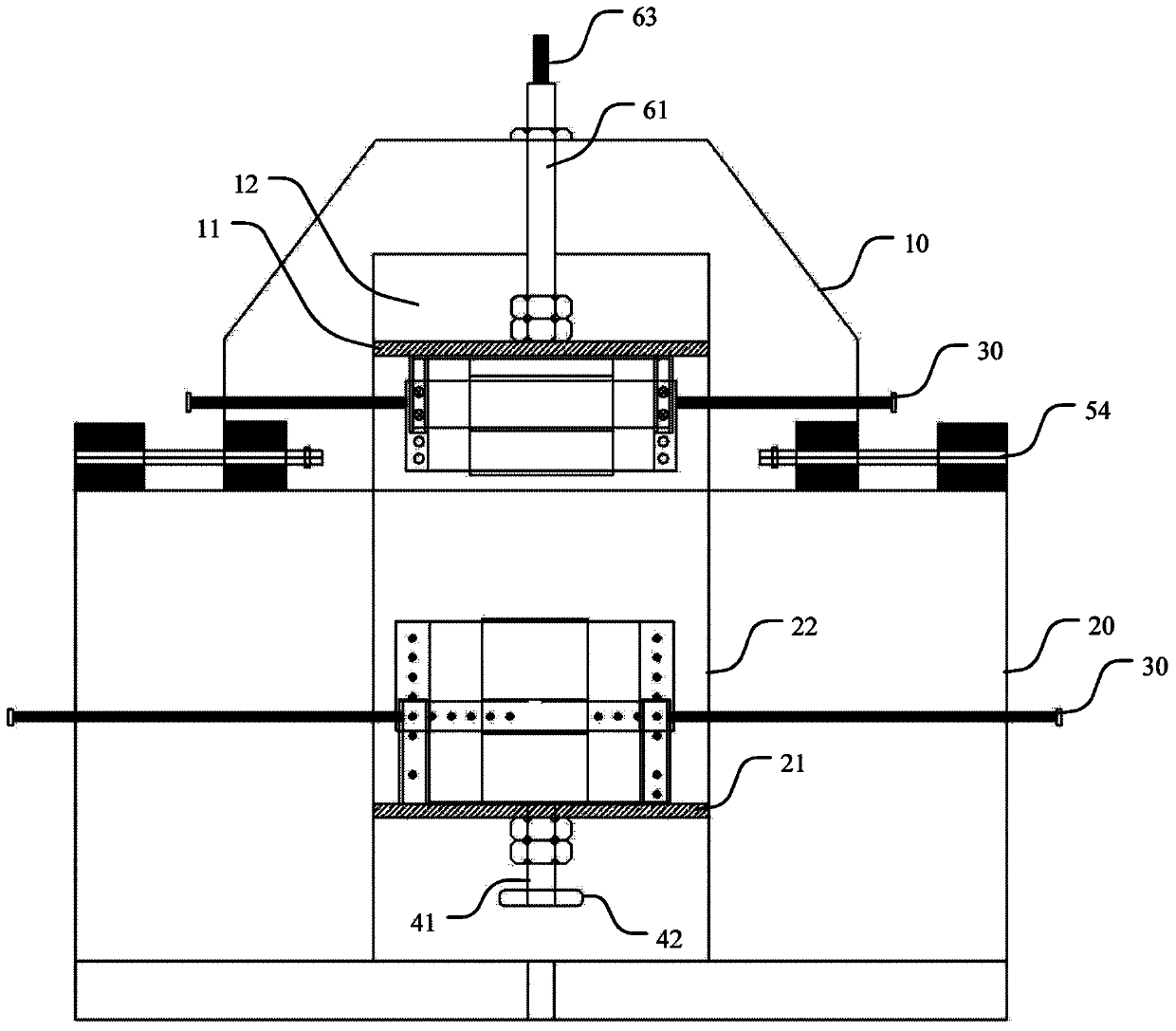

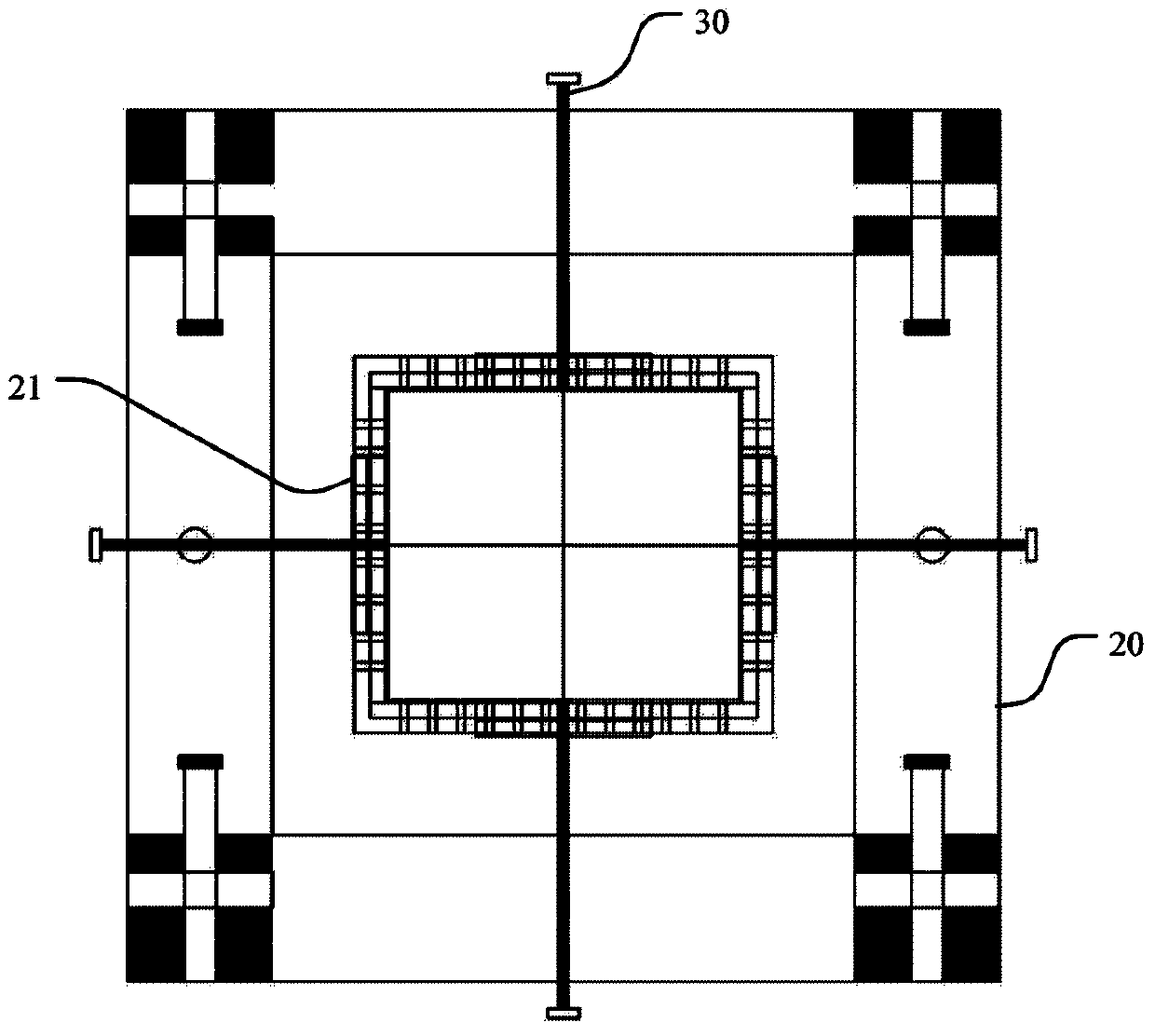

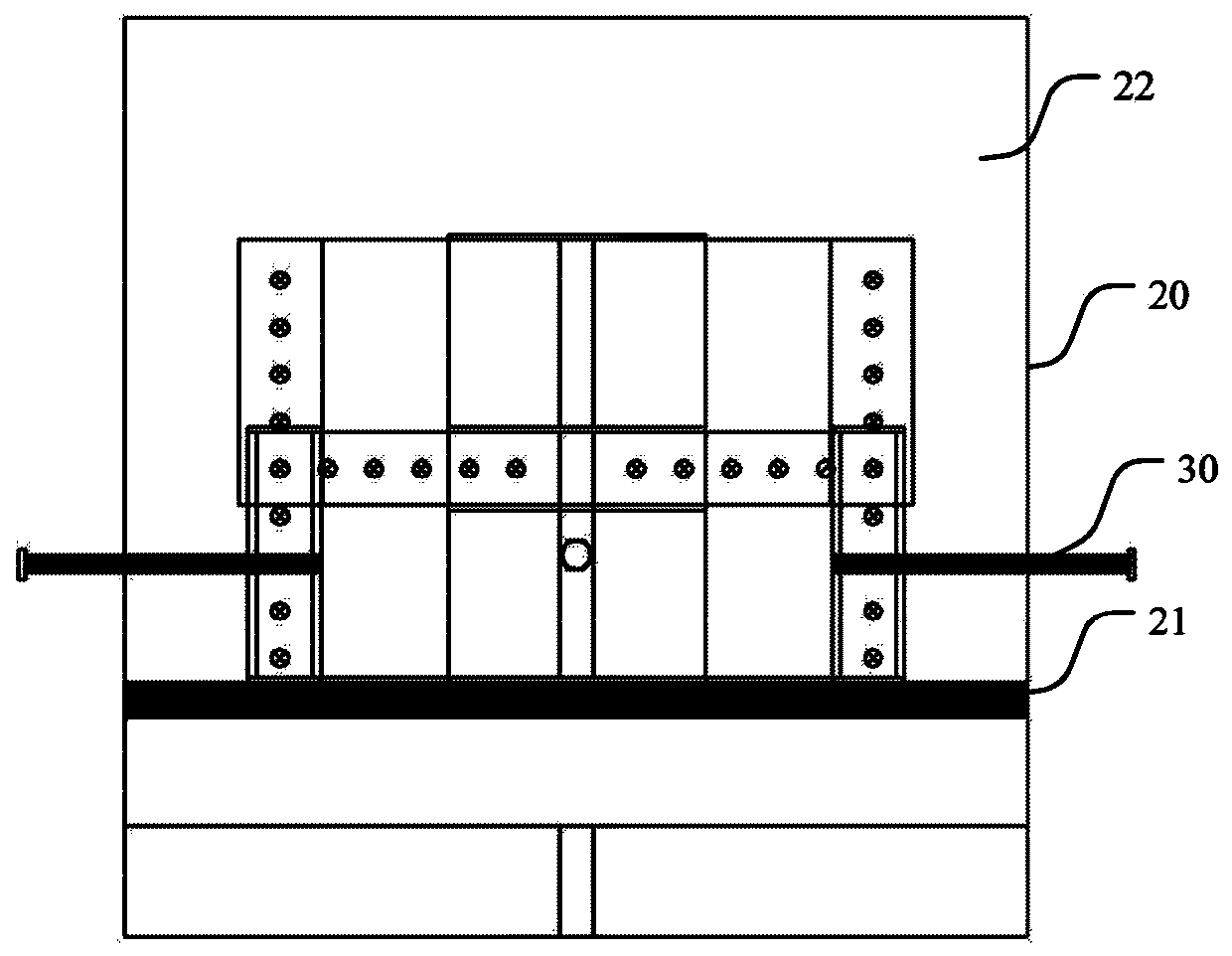

[0039] figure 1 is a schematic structural diagram of an interlaminar direct shear test device according to an embodiment of the present invention. An embodiment of the present invention provides an interlayer direct shear test device for a pavement structure double-layer specimen, which includes an upper shear box 11, a lower shear box 21, a vertical loading device and a lateral loading device. The opening of the upper shear box 11 faces downward, and it is used to accommodate the superstructure of the double-layer test piece of the tested road surface structure; the opening of the lower shear box 21 faces upward, and it is used to accommodate the double-layer test piece of the tested road surface structure The substructure; the vertical loading device is used to directly or indirectly apply a predetermined vertical load to the double-layer test piece of the pavement structure under test so that the double-layer test piece of the pavement structure under test can bear the predet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com