Soil engineering triaxial shear test equipment based on MTS electro-hydraulic servo tester

An electro-hydraulic servo and three-axis shearing technology, which is applied in the direction of applying a stable shear force to test the strength of materials, can solve the problems of reducing the scalability of the MTS electro-hydraulic servo testing machine, and achieve small occupied space and measurement accuracy. High and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

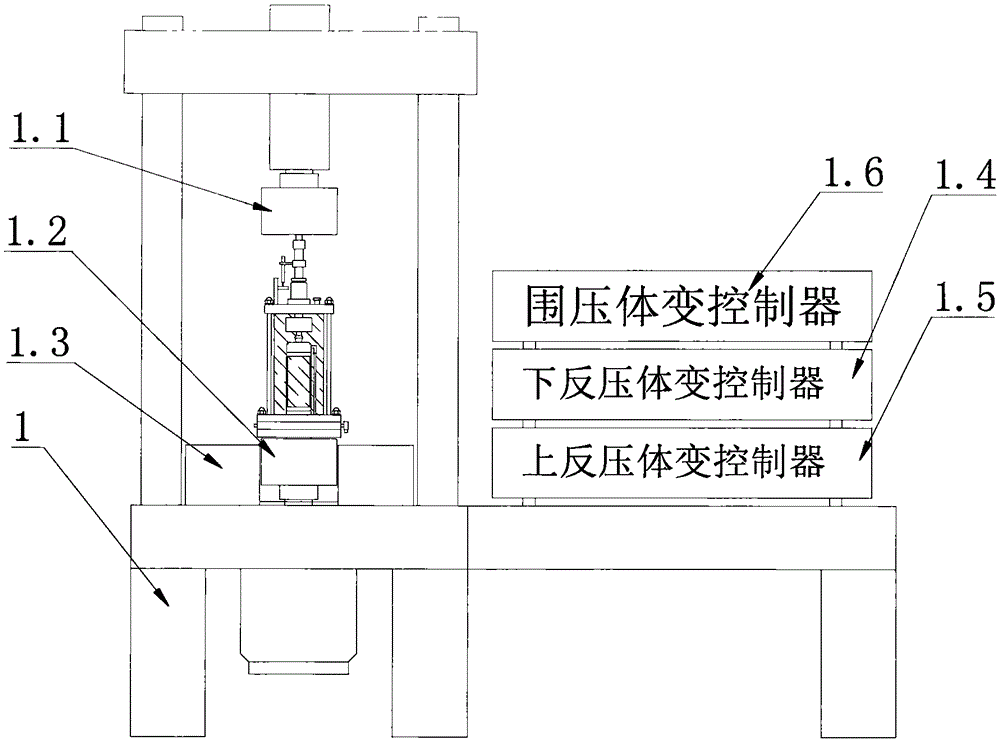

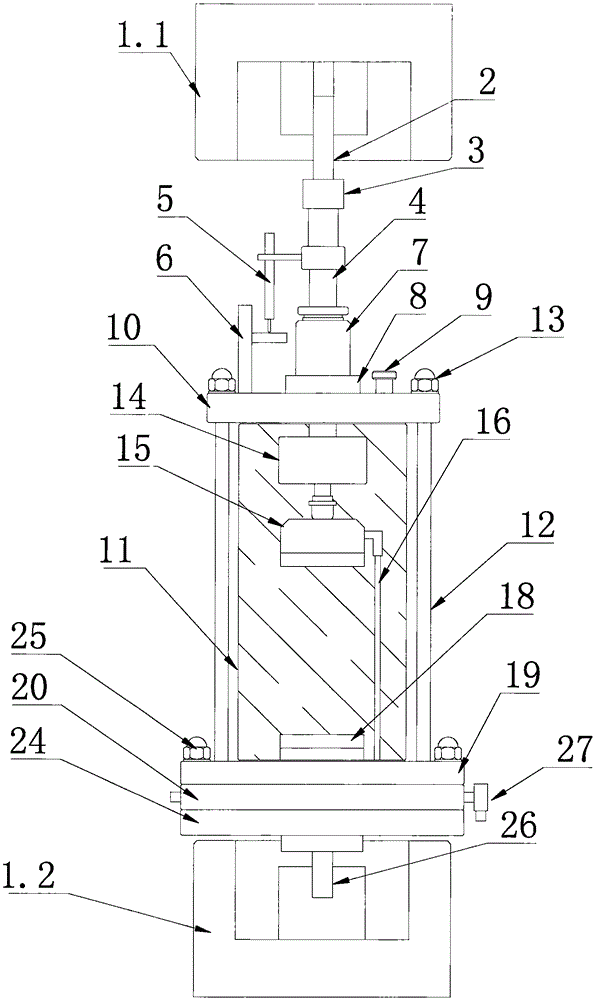

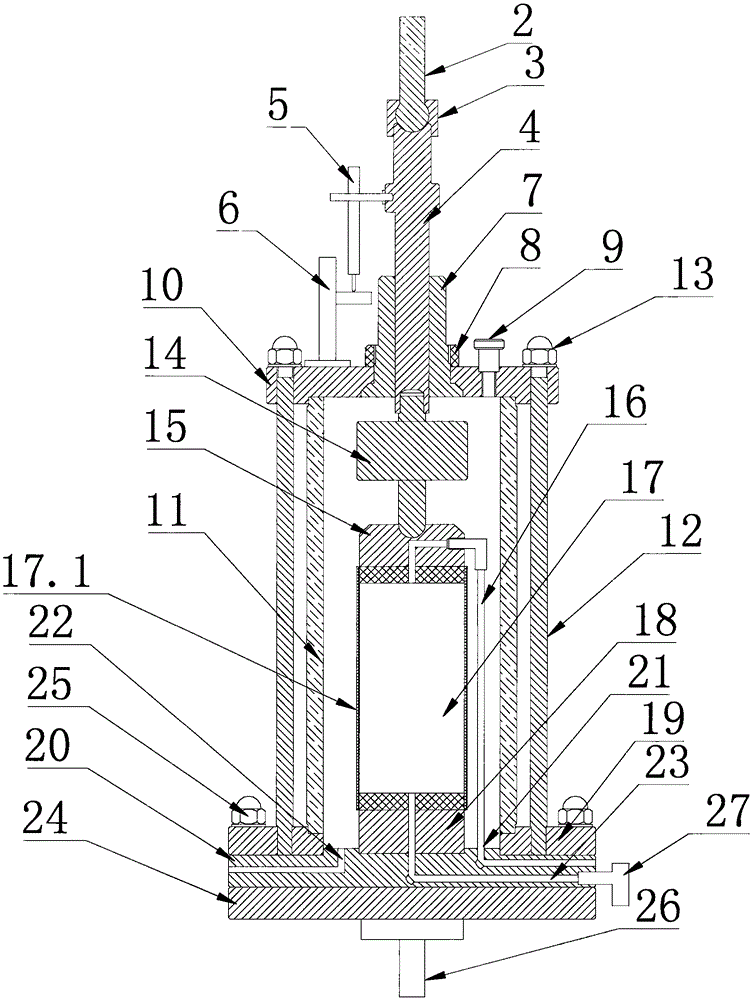

[0021] Such as figure 1 , figure 2 , image 3 , a geotechnical triaxial shear test equipment based on MTS electro-hydraulic servo testing machine, including MTS electro-hydraulic servo testing machine 1, chuck 1.1 on the MTS electro-hydraulic servo testing machine of MTS electro-hydraulic servo testing machine 1, MTS electro-hydraulic servo testing machine A geotechnical triaxial shear test device is installed on the lower chuck 1.2 of the servo testing machine; the geotechnical triaxial shear test device includes a test pressure chamber, and the test pressure chamber includes a tempered glass cover 11, two sides of the tempered glass cover 11 The upper end cover 10 of the pressure chamber and the lower end cover 19 of the pressure chamber are respectively installed at the ends, and the lower end cover 19 of the pressure chamber is installed on the base 20 of the pressure chamber through the fixing bolt 25 of the lower end cover; 4 connection, the dowel sleeve 7 is sealed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com