Acoustic emission test device for rock mechanics direct shear process

A testing device and rock mechanics technology, applied in the direction of measuring devices, scientific instruments, instruments, etc., can solve the problems of testing, inability to perform high-precision, and lack of analysis system devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

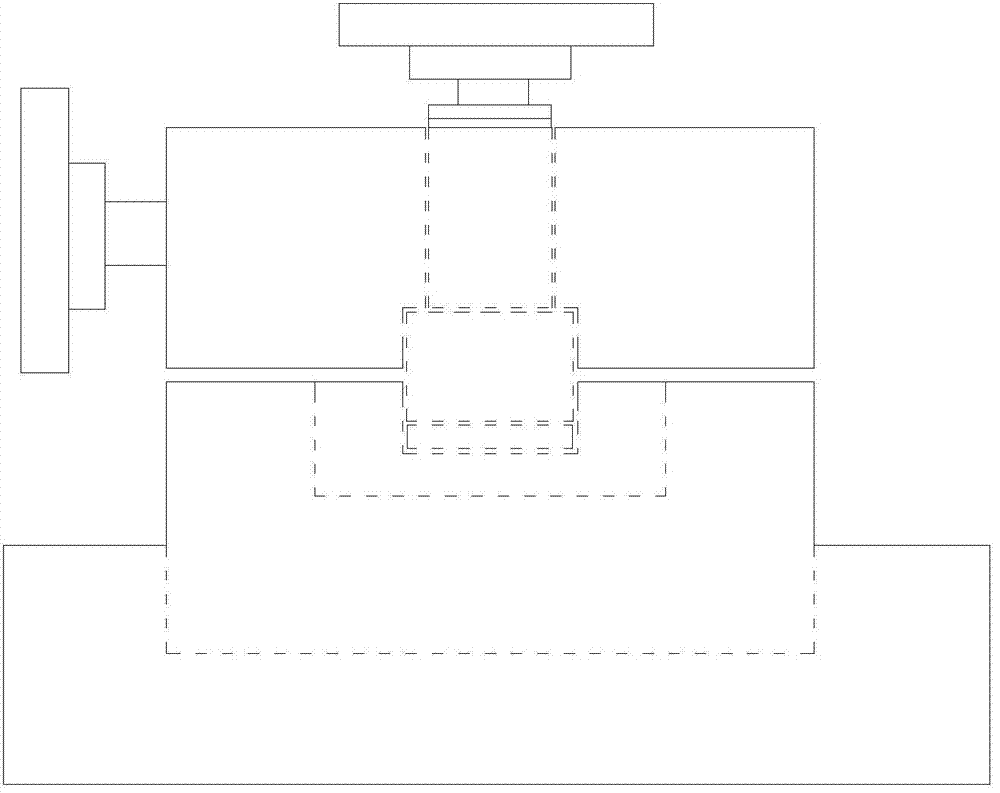

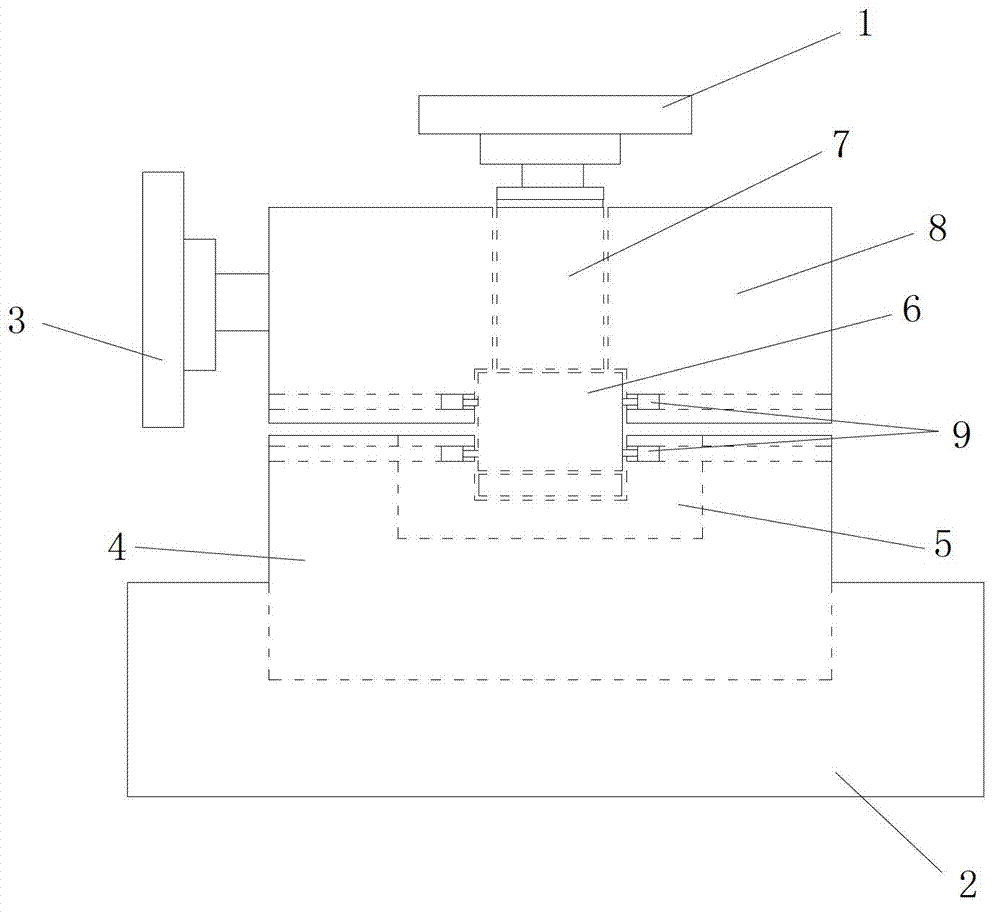

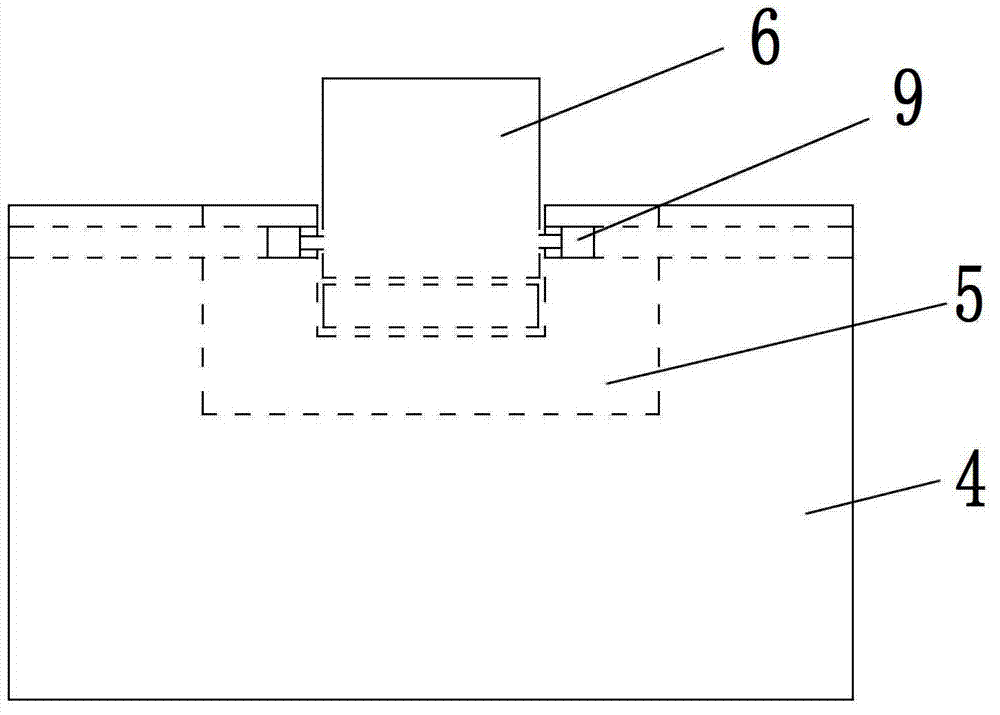

Image

Examples

Embodiment Construction

[0021] In order to further understand the content of the invention, features and effects of the present invention, the following examples are given hereby, and the accompanying drawings are described in detail as follows: First, a group of sandstone samples are selected, and the collected sandstone samples are processed into cube specimens with a length, width, and height of 40mm by wet processing method. The surface of the test piece is graded and polished with sandpaper, so that the flatness error of each end surface is controlled within 0.02mm. The test considered three different water states with saturation degrees of 0%, 50% and 100%, respectively. According to the requirements of the relevant test specifications, the specific treatment methods for the specimens in three typical water-containing states are as follows: (a) The saturation is 0%: put the specimen in an oven at 105°C for 48 hours; (b) The saturation is 50% : Take the saturated water content as the standard, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com