True triaxial shear rock mass shearing seepage test device suitable for high seepage pressure, and test method of test device

A high osmotic pressure, test device technology, used in measurement devices, permeability/surface area analysis, suspension and porous material analysis, etc. The effect of precise control and measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

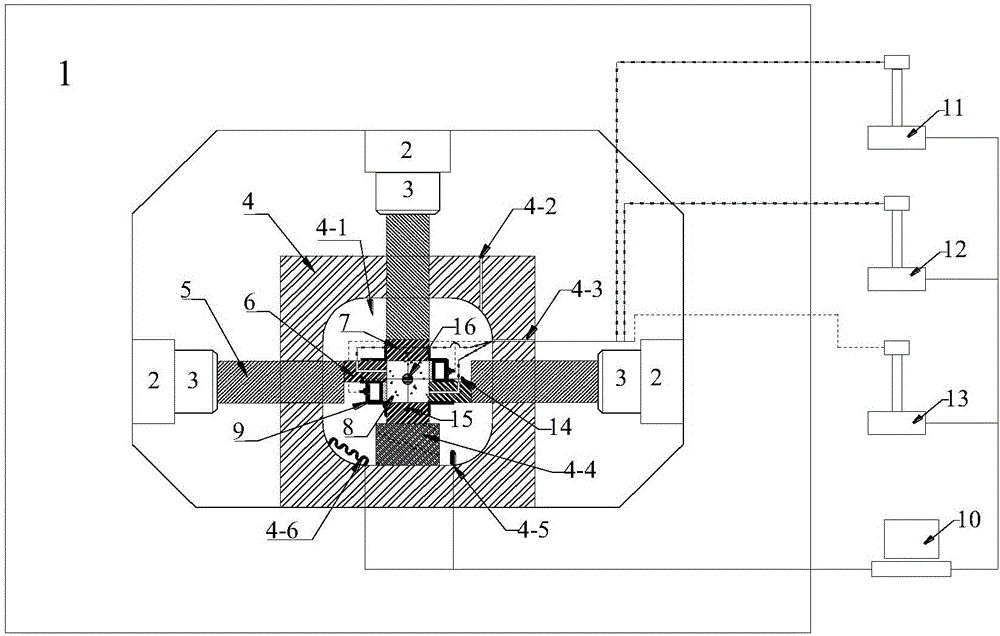

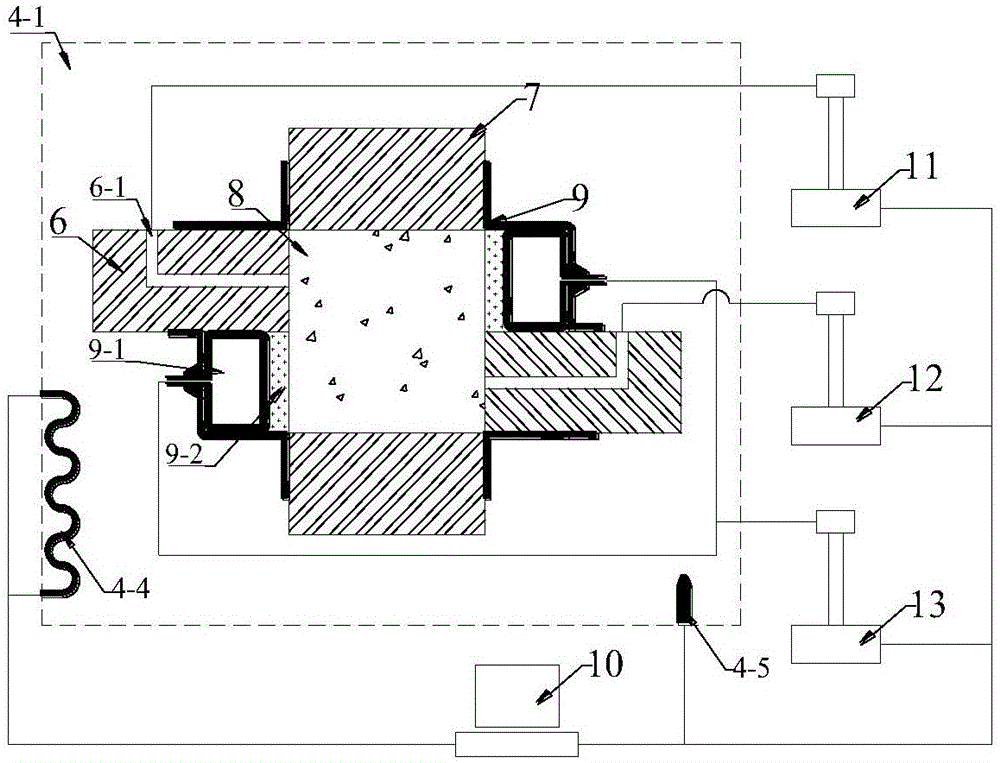

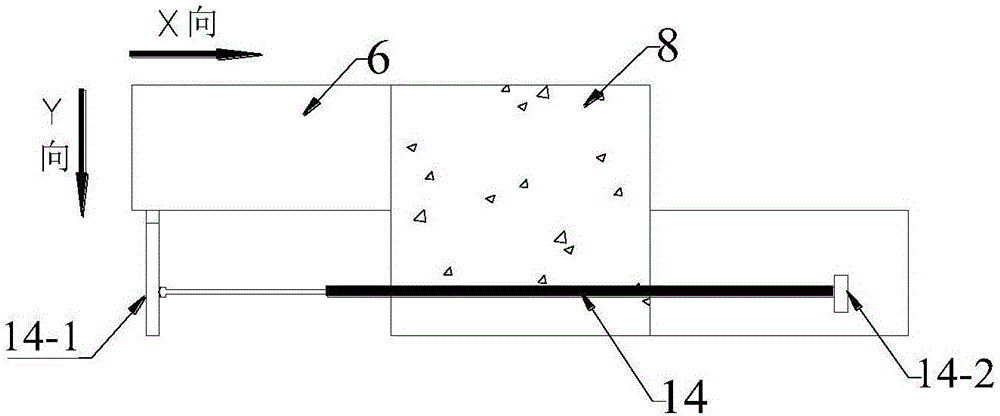

[0080] Below in conjunction with accompanying drawing and embodiment describe in detail:

[0081] 1. Overall

[0082] Such as figure 1 , 2 , 3, 4, the device includes a rigid frame 1, an oil cylinder 2, a pressure sensor 3, a high-pressure cavity 4, a pressure column 5, a shear plate 6, a normal pressure plate 7, a rock sample 8, a sealing rubber sleeve 9, a computer 10, Fluid injection metering pump 11, fluid return metering pump 12, confining pressure tracking pump 13, X-direction displacement sensor 14, Y-direction displacement sensor 15, Z-direction displacement sensor 16;

[0083] Its location and connection relationship are:

[0084] A high-pressure chamber 4 is arranged at the bottom of the rigid frame 1, and an assembly composed of a shear plate 6, a normal pressure plate 7, a rock sample 8 and a sealant sleeve 9 to form a shear seepage seal is arranged in the high-pressure chamber 4 , the structure of the assembly is: the rock sample 8 is placed in the center of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com