Compression shear test device

A test device and splint technology, applied in the direction of applying stable shear force to test the strength of materials, etc., can solve the problems of non-continuous adjustment of angle, shortened service life of the device, poor integrity of the device, etc., and achieve wide application range and long service life , the effect of good self-stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing, the present invention is described in further detail:

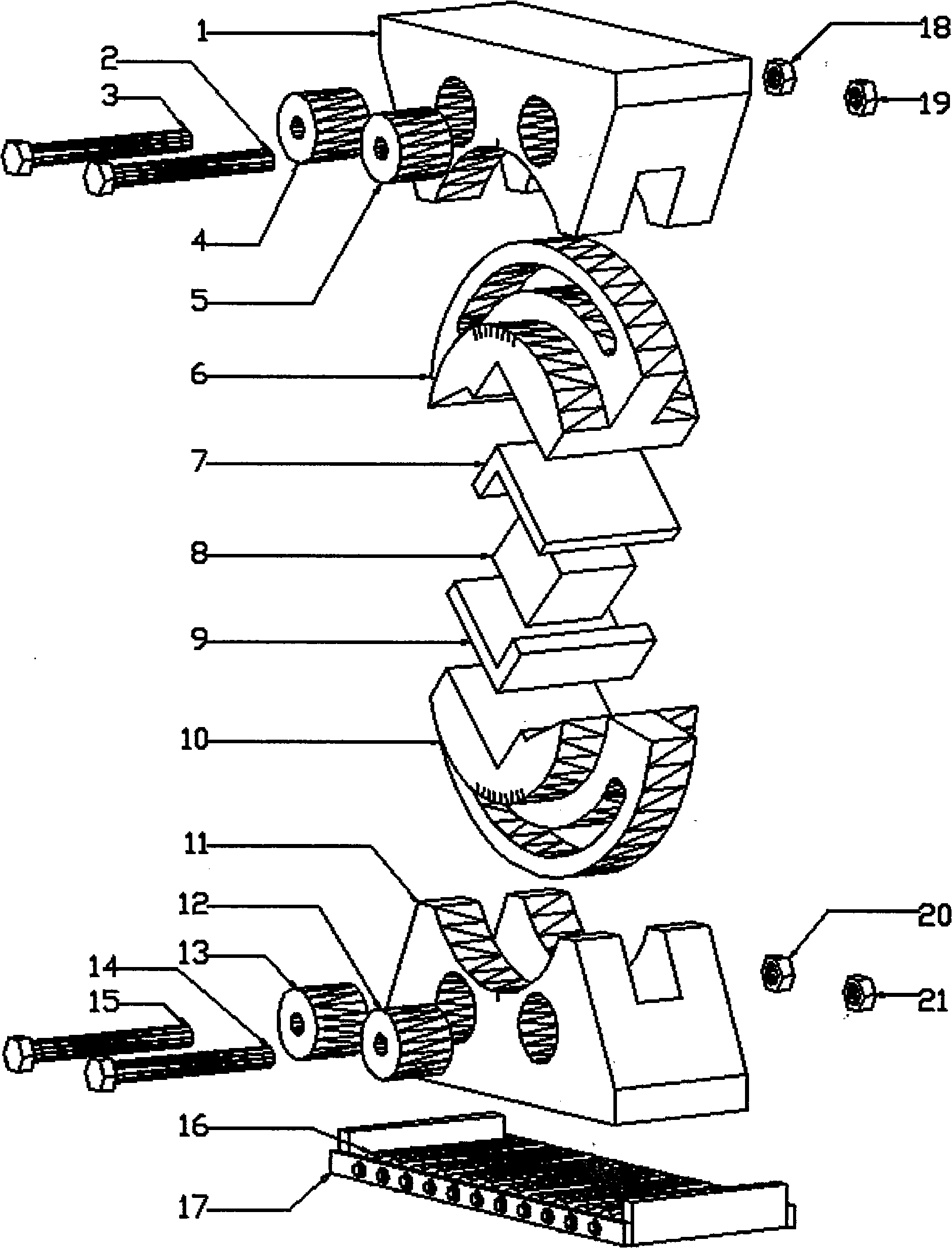

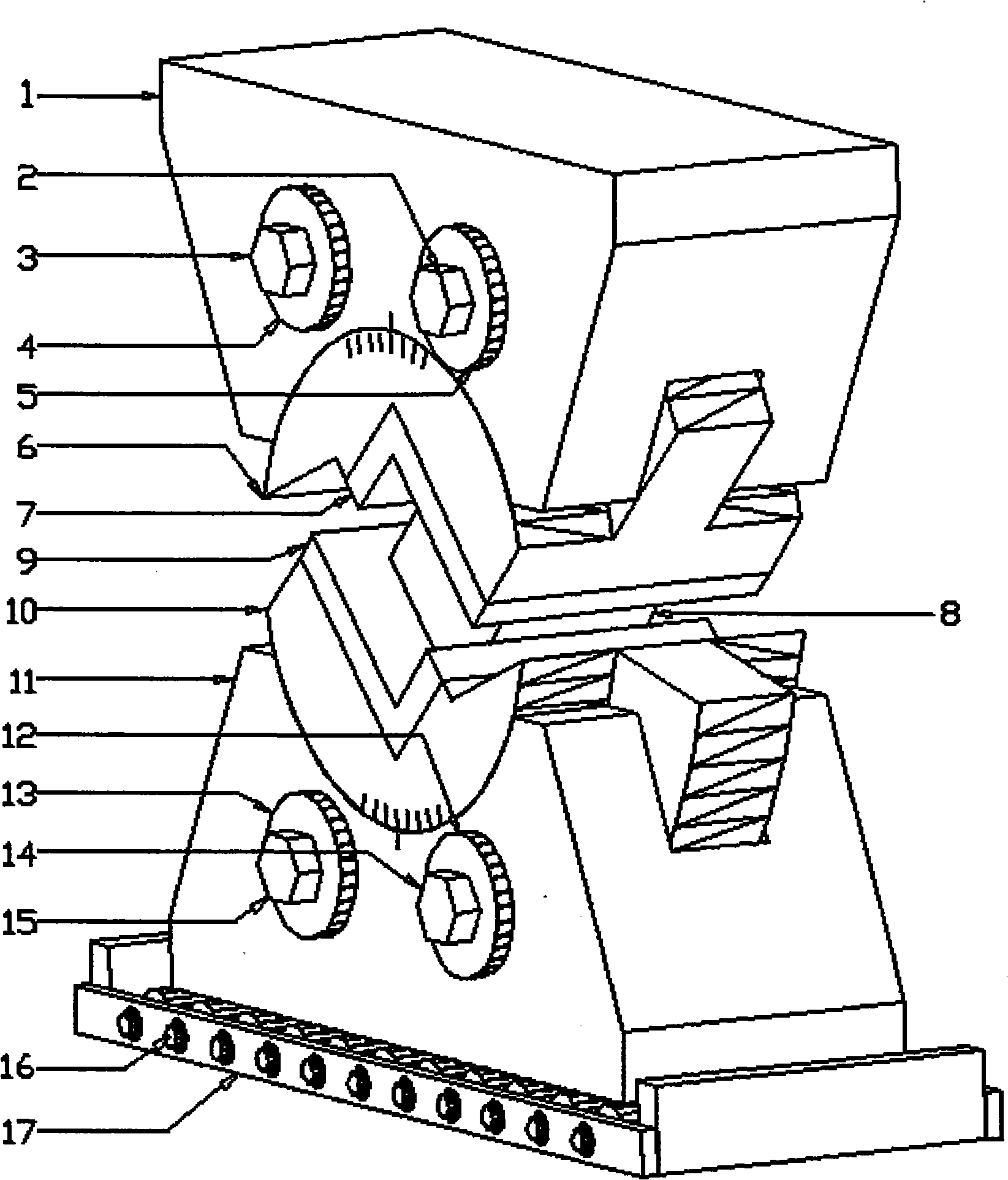

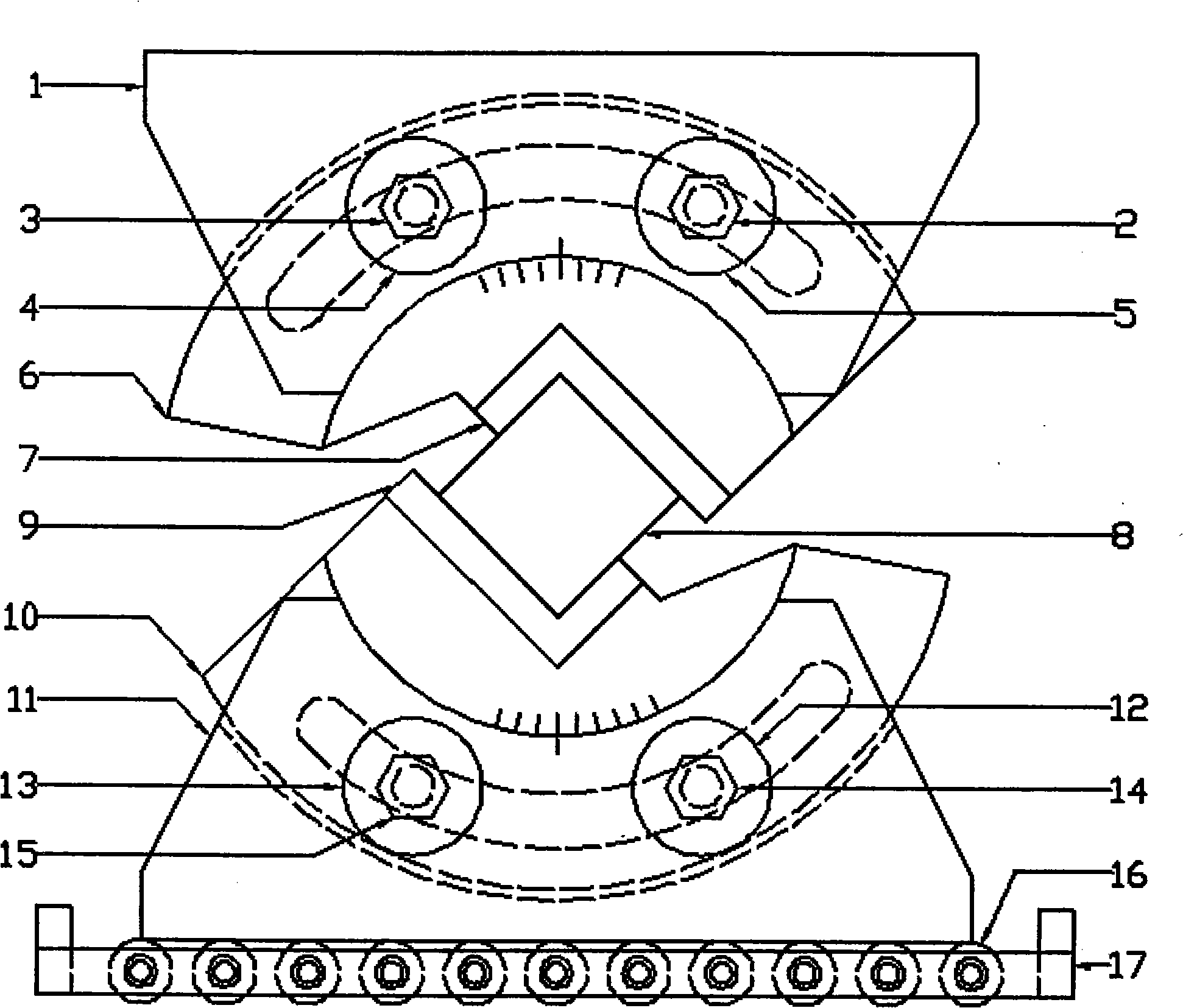

[0023] according to figure 1 , figure 2 , image 3 It can be seen that the device includes splints 1, 11, cylindrical pads 4, 5, 12, 13, variable angle plates 6, 10, right-angled pads 7, 9, rollers 16, roller frames 17, bolts 2, 3, 14, 15, nuts 18, 19, 20, 21, the rock sample 8 located in the middle of the device is the implementation object of the present invention.

[0024] first based on figure 1 Describe the characteristics and functions of each component:

[0025] The front and rear sides of the first splint 1 have holes, and the positions of the holes should match the annular holes on the edge of the first angle-changing plate 6. The principle is not to affect the rotation of the first angle-changing plate 6 to a sufficient angle. The diameter of the front hole matches the first and second cylindrical spacers 4,5, and the diameter of the rear hole matches ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com