Composite interlaminar shear performance testing method

A composite material layer and testing method technology, applied in the field of composite materials, can solve the problems of interlaminar shear and tension-compression mixed failure, difficulty in accurately obtaining interlaminar shear properties, weak interlaminar properties of test data, etc. The effect of processing links, cost reduction and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

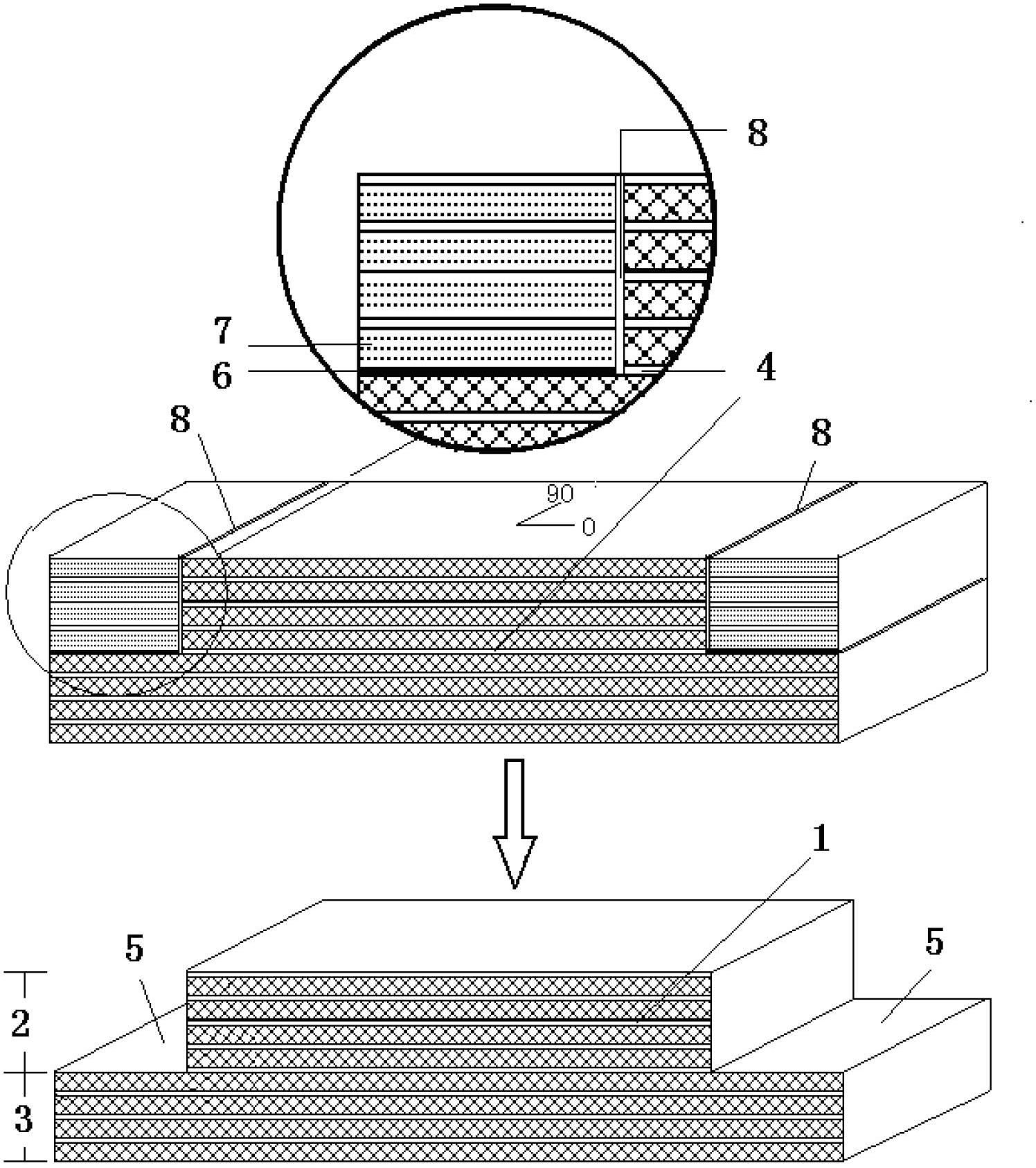

[0023] The following structural drawings describe the present invention in detail. The test method includes the following two steps:

[0024] (1) Preparation of test pieces

[0025] Specimen 1 is a block with a boss 2 in the middle. Firstly, it is laid continuously, and then the boss base 3 is laid. For the laying of layers, and at the 5 shoulders on both sides of the boss 2, first lay a layer of film 6 for release, and then continuously lay the 90-degree layer 7 on the film 6 for release, and the 90-degree layer 7 and the part of the boss 2 The laying layers are spliced in parallel until the laying is completed; the laid block is formed, and after forming, the film 6 for demoulding on both sides of the boss 2 and the continuous laying part above 90 degrees are spliced along the film 6 for demoulding and splicing The interface 8 is peeled off to form a boss-type test piece 1;

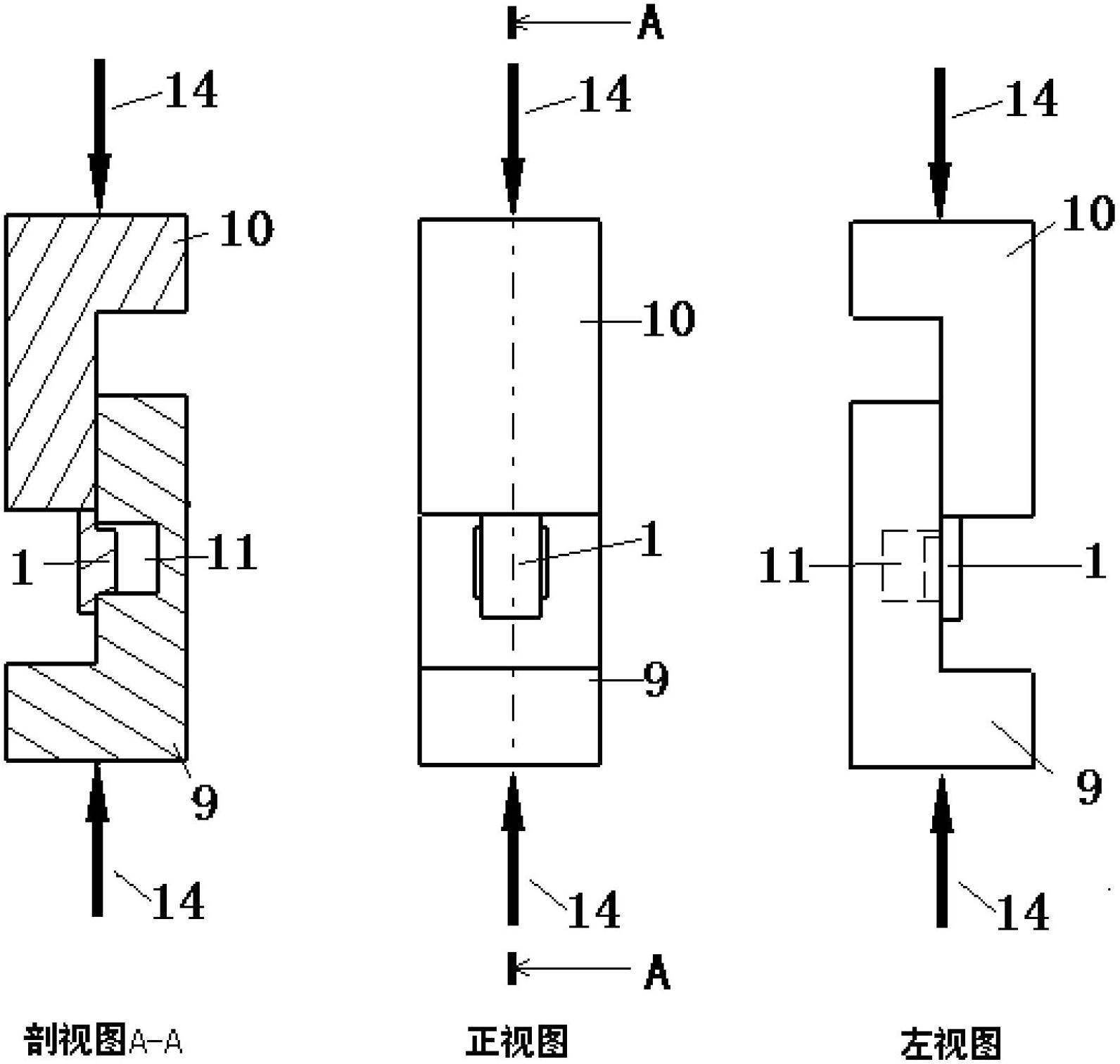

[0026] (2) Preparation of test device

[0027] The test device consists of two L-shaped comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com