Torque testing device

A torque testing and testing mechanism technology, applied in measuring devices, using stable torque to test material strength, and measuring torque/torsional force when tightening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

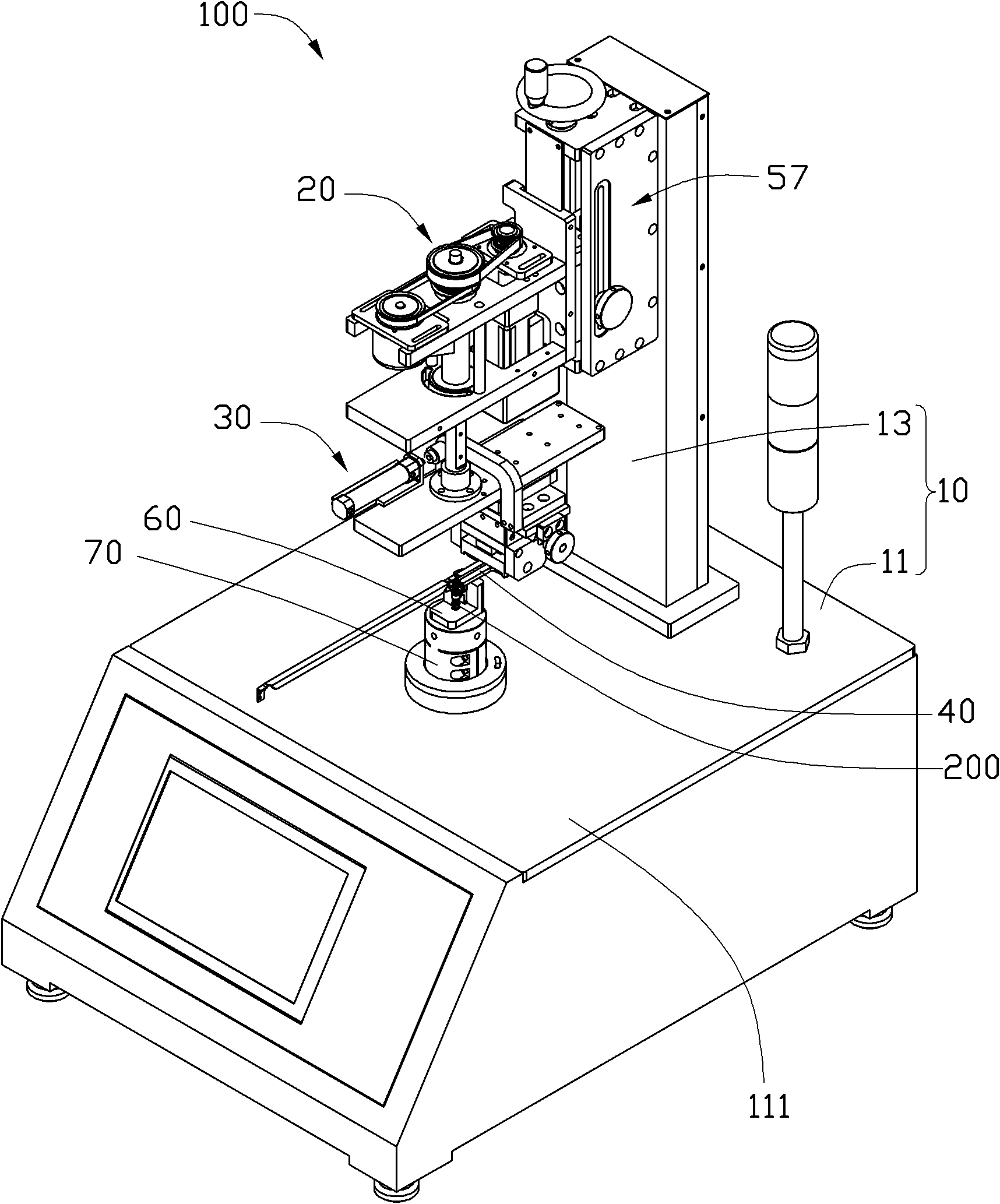

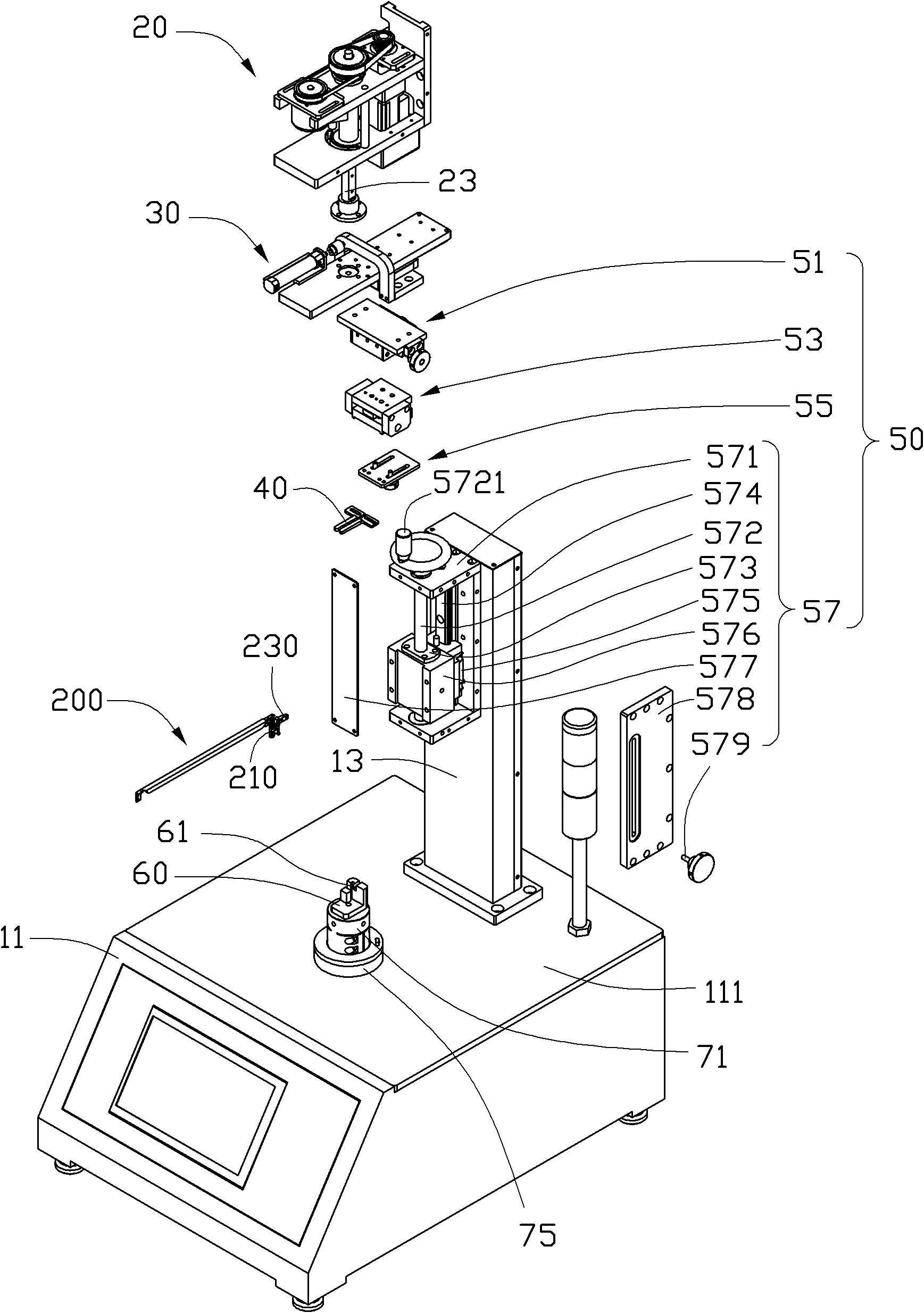

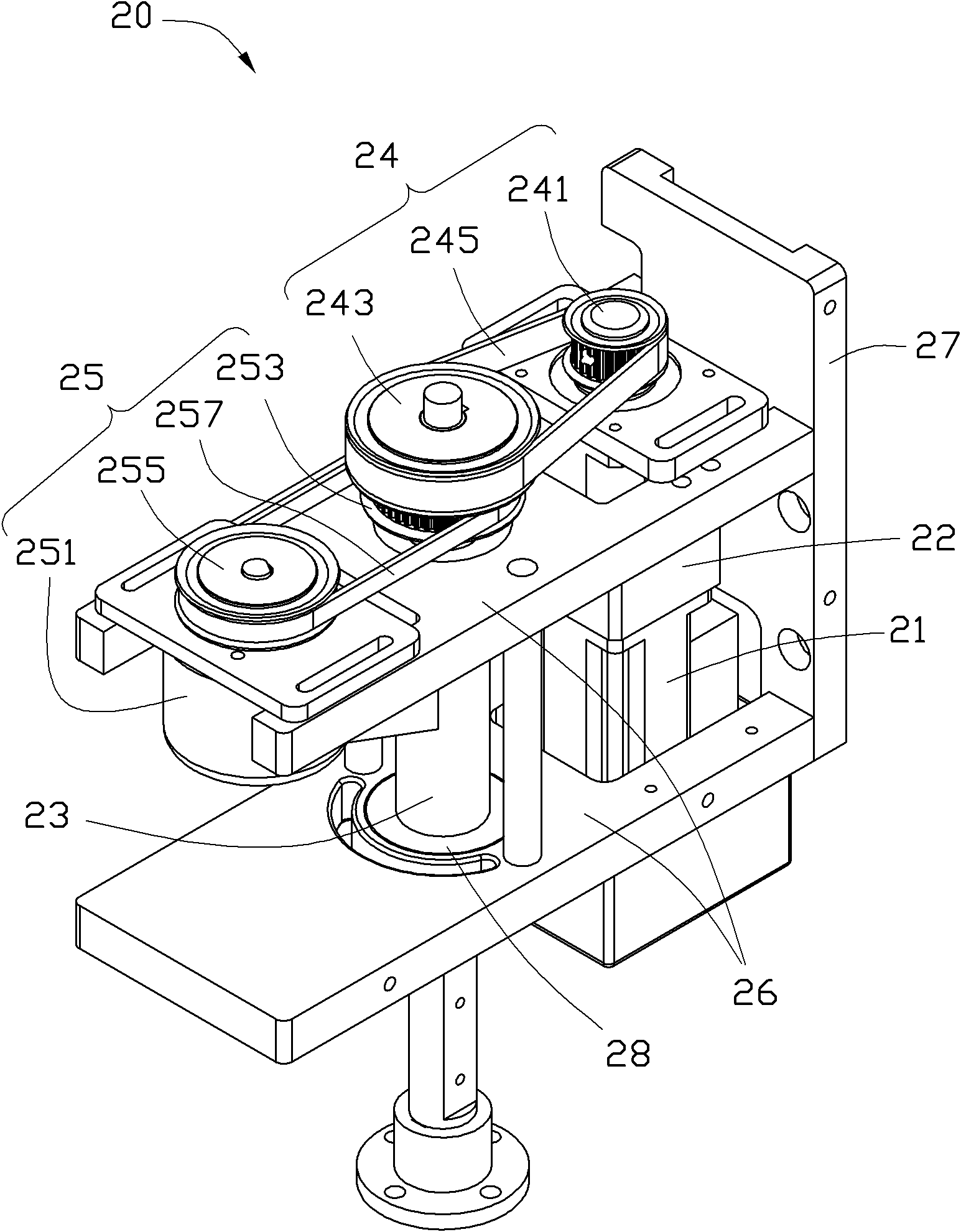

[0083] see figure 1 and figure 2, the torque testing device 100 according to the preferred embodiment of the present invention is used to measure the torque of the hinge 200 . The hinge 200 includes a fixing part 210 and a rotating part 230 rotatable relative to the fixing part 210 . The torque testing device 100 includes a mounting base 10 , a driving mechanism 20 , a telescoping mechanism 30 , a chuck 40 , an adjusting mechanism 50 , a hinge mounting base 60 and a testing mechanism 70 fixedly connected to the hinge mounting base 60 . The fixing part 210 of the hinge 200 is fixed on the hinge mounting seat 60; the rotating part 230 is clamped by the clamp 40; the driving mechanism 20 drives the rotating part 40 to rotate the rotating part 230 and to the The fixing member 210 exerts force; the testing mechanism 70 tests the torque of the hinge 200 through the force borne by the hinge mounting base 60 and the fixing member 210 . The adjusting mechanism 50 is used for adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com