White car body static stiffness restriction device and static stiffness detection method

The technology of a restraint device and a detection method is applied in the field of restraint devices for the static stiffness of the body-in-white, and can solve the problems that do not involve the measurement method of bending deflection, signal acquisition and data processing, the large difference between the calculated stiffness and the actual stiffness, and the error of the bending stiffness test result. and other problems, to achieve the effect of improving the structural performance of the automobile body, simplifying debugging and measurement, and reducing the cost of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

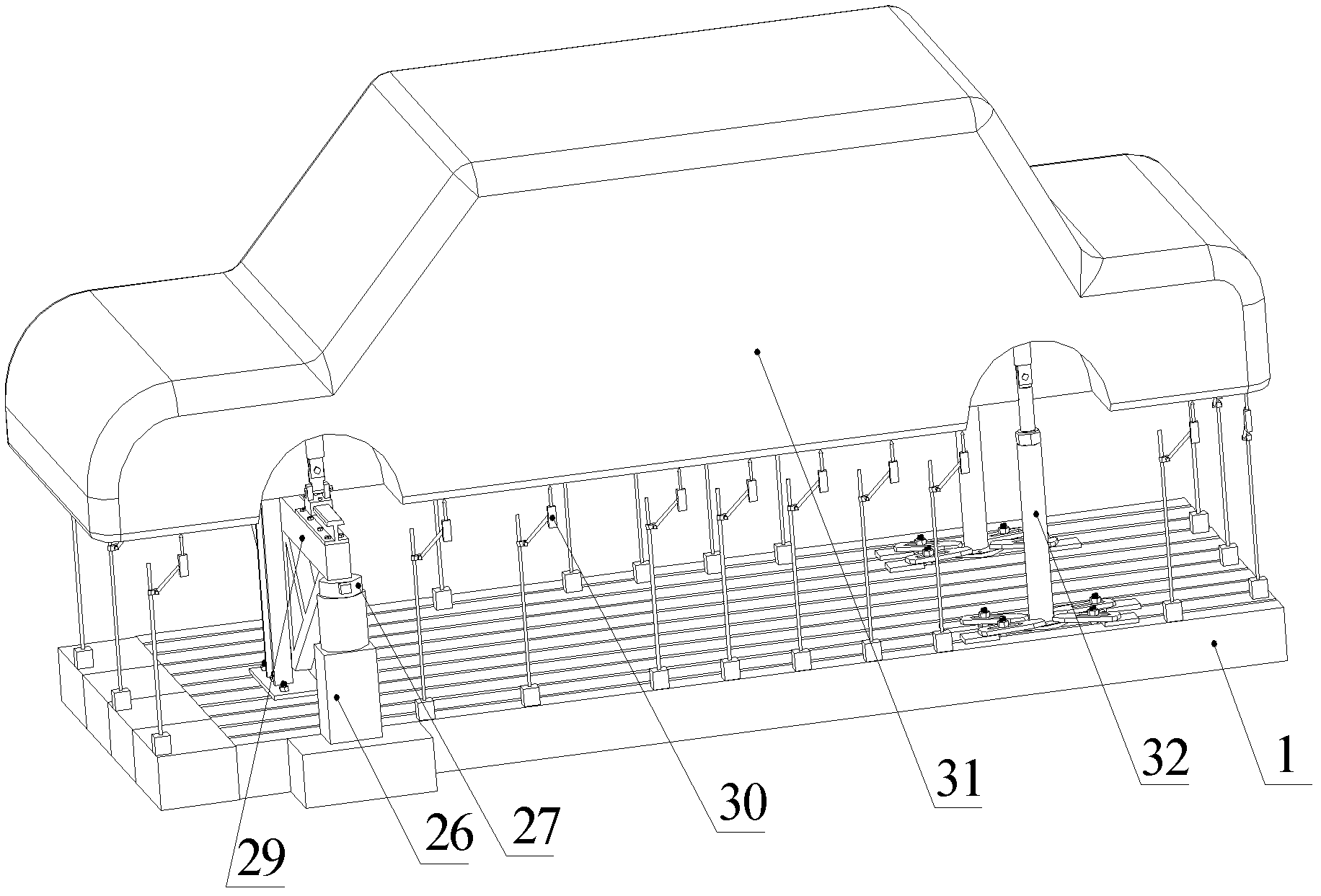

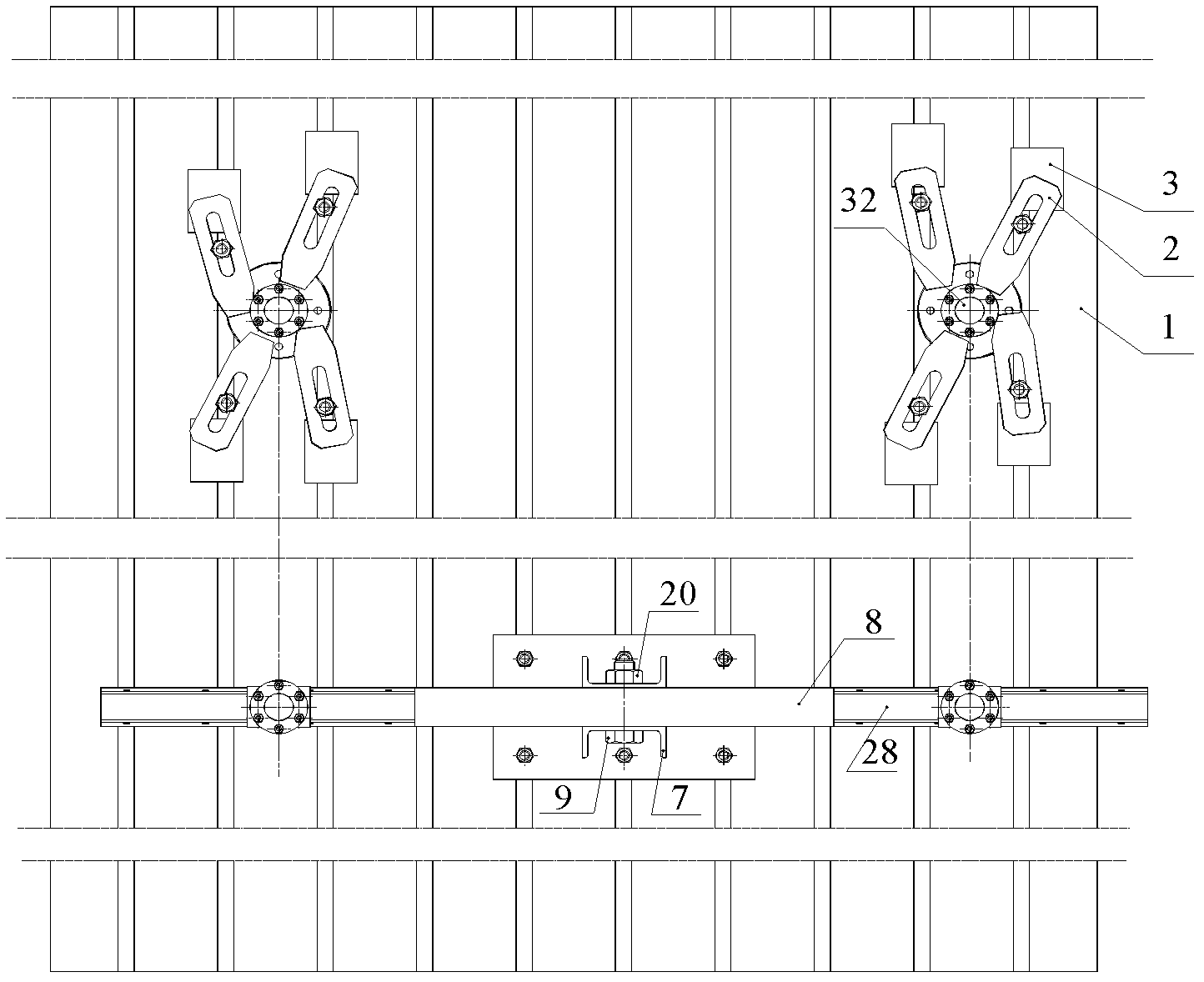

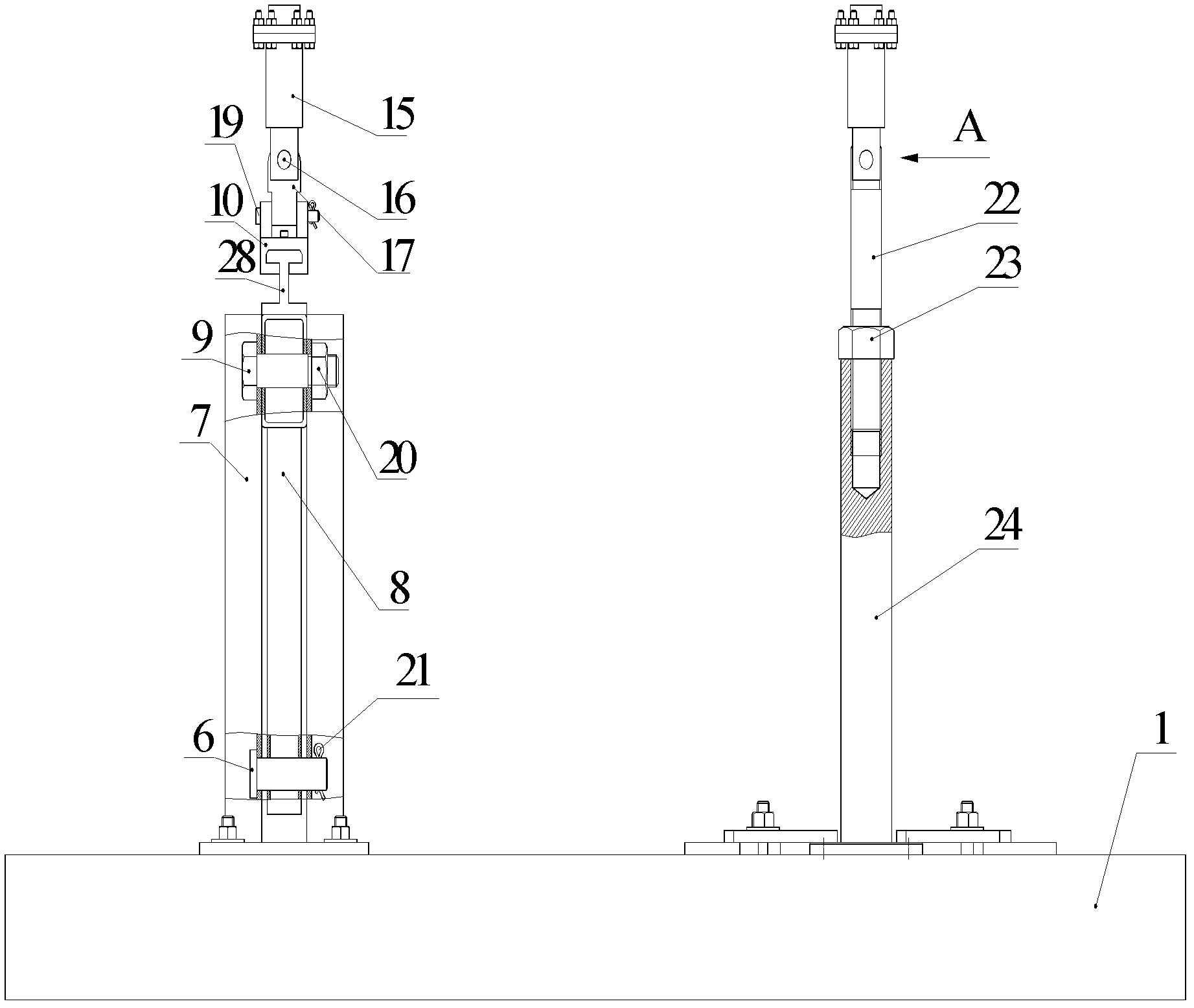

[0022] Such as figure 1 As shown, the restraint device for measuring the static stiffness of the body in white includes a T-slot test bench floor 1 arranged directly below the body-in-white 31, and a front support frame 29 and a rear support frame 32 are installed on the T-slot test bench floor 1. The frame 29 is vertically supported between the front part of the body-in-white 31 and the T-slot test bench floor 1, and the rear support frame 32 is vertically supported between the rear part of the body-in-white 31 and the T-slot test bench floor 1. One side of the front support frame 29 is equipped with a torsional loading device, which is composed of a pressure sensor 27 and a hydraulic jack 26, and the pressure sensor 27 is arranged on the hydraulic jack 26. A number of displacement sensors 30 are arranged around the bottom surface of the body-in-white 31. The displacement sensors 30 are used to measure the displacement of the body-in-white 31 after the load is applied, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com