Novel kitchen waste treatment system and technology based on intelligent monitoring

A technology of food waste and treatment system, which is applied in the field of new food waste treatment system, can solve problems such as imperfect food waste collection, transportation and treatment systems, poor stability of orderly treatment process, and affecting the efficiency of food waste treatment. , to achieve the effect of saving labor cost, humanized operation and efficient processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] According to the claims and disclosed content of the present invention, the specific embodiments of the present invention are as follows.

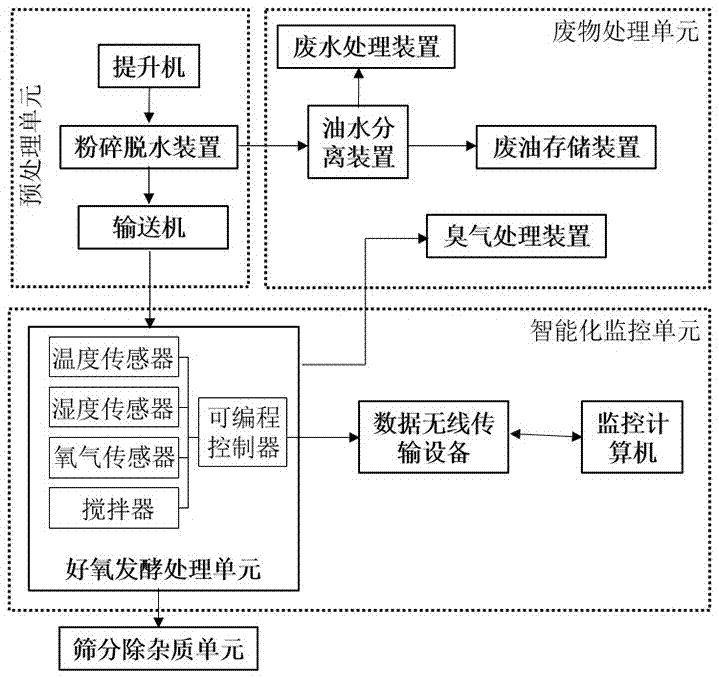

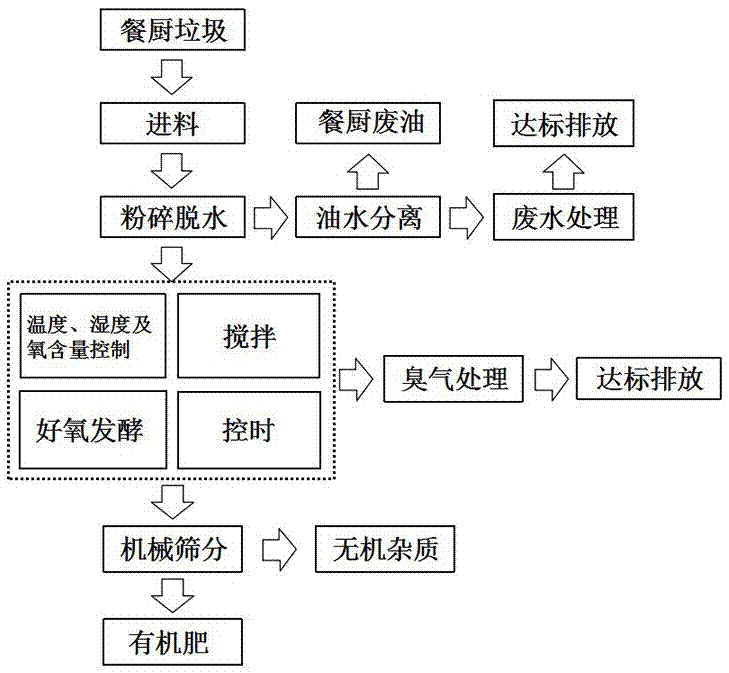

[0023] like figure 1 As shown, the present invention provides a new type of food waste treatment system based on intelligent monitoring, including a pretreatment unit, an aerobic fermentation treatment unit, a screening and impurity removal unit, a waste treatment unit and an intelligent monitoring unit.

[0024] The pretreatment unit includes a hoist, a conveyor, a crushing and dehydrating device, and is used for feeding, crushing and dehydrating the kitchen waste.

[0025] The aerobic fermentation processing unit includes an aerobic fermentation bin and a stirrer in the bin, a ventilation device, a temperature sensor, a humidity sensor, an oxygen sensor and a programmable controller. The aerobic fermentation bin is connected with the outlet of the pretreatment unit through a screw conveyor. The stirrer, the temperature sensor, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com