Low air pressure test device

A test device and low-pressure technology, applied in the field of space environment simulation, can solve problems such as inability to stabilize pressure, inability to adjust depressurization rate, and pressure reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

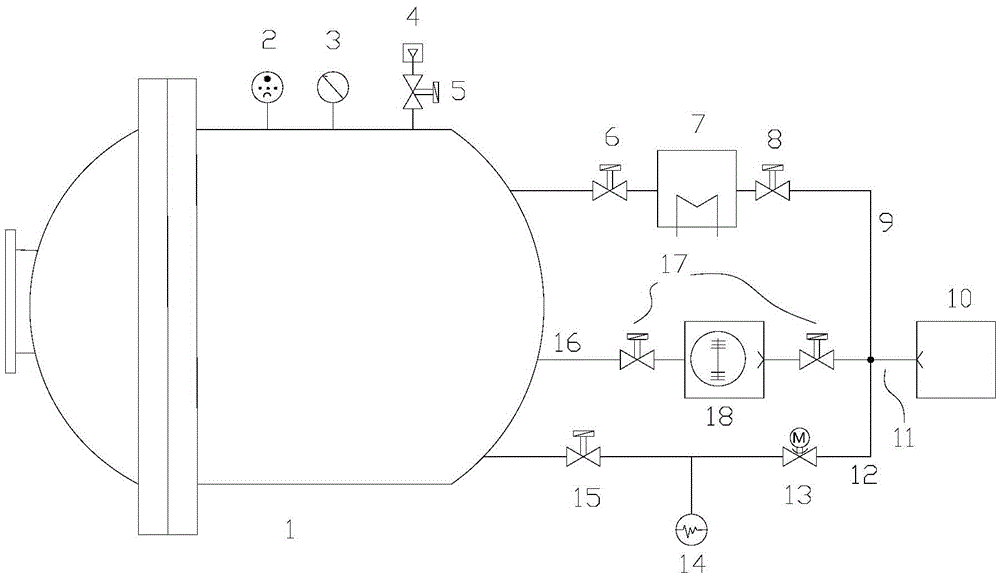

[0025] Such as figure 1 As shown, the low pressure test device provided by the present invention includes a vacuum tank 1, an air extraction system, a pressure measurement system, an inflation system and a control system.

[0026] The vacuum tank 1 is composed of a tank body and a tank cover. The tank body and the tank cover can be closed to form a closed space, and the test products used in the test are placed in the closed space.

[0027] The air extraction system includes two air extraction lines, wherein the first air extraction line 12 is connected in series with a first pneumatic valve 15 and an electric pressure regulating valve 13, and the second air extraction line 16 is connected in series with a second pneumatic valve 17 and molecular pump 18. One end of the first exhaust pipeline 12 and the second exhaust pipeline 16 are connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com