Material increase manufacturing method of multi-scale biomimetic artificial bone support

A technology of additive manufacturing and artificial bone, applied in the field of additive manufacturing, can solve the problems of secondary disinfection and preservation of microspheres, and the difficulty of quantitative control of pore size and porosity, so as to achieve a wide range of materials and reduce clinical application. Accurate and controllable effect of cost and dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

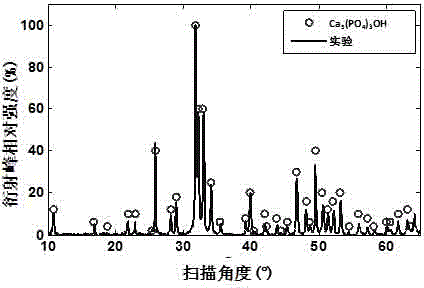

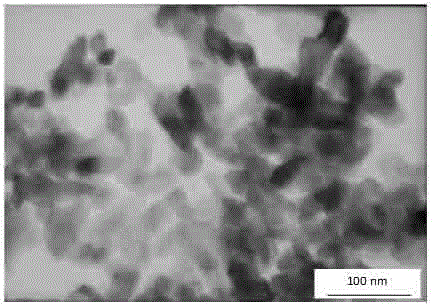

[0026] The inorganic and organic materials of human bones are mainly hydroxyapatite and collagen, and the realization of additive manufacturing of such degradable composite materials can lay a technical foundation for bone tissue repair.

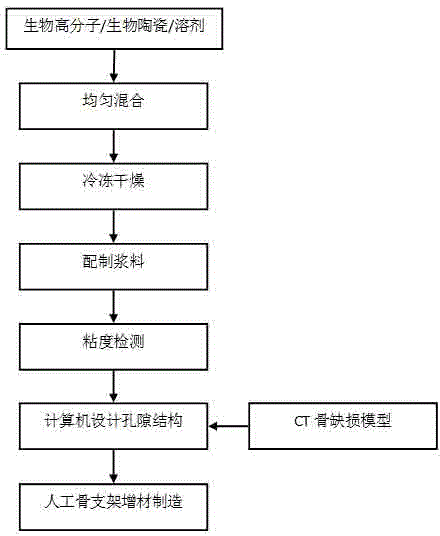

[0027] 1) Using 30% by mass of collagen and 70% by mass of nano-hydroxyapatite as the artificial bone matrix material, mixed with 6 times deionized water, and freeze-dried to obtain a homogeneous powder;

[0028] 2) Mix the powder obtained in step 1 with 5 times deionized water to obtain a slurry with a viscosity of 320,000 centipoise, and vacuum exhaust;

[0029] 3) Extrude the liquid slurry obtained in step 2 by quantitative extrusion with a screw pump;

[0030] 4) Using the XYZ motion device, according to the three-dimensional geometric model of the bone defect obtained from the CT scan, the pore structure parameters inside the geometric model are designed through a computer program: square pores, the hole side length is 0.8mm, and the po...

Embodiment 2

[0032] Adding bone morphogenic protein (Bone Morphogenetic Protein, BMP) to bone matrix materials can better promote bone repair.

[0033] 1) Using 8% by mass of BMP, 32% by mass of collagen and 60% by mass of nano-calcium-deficient hydroxyapatite as the artificial bone matrix material, mixed with 8 times deionized water, and freeze-dried to obtain a uniform Quality powder;

[0034] 2) Mix the powder obtained in step 1 with 6 times of deionized water to obtain a slurry with a viscosity of 250,000 centipoise, and vacuum exhaust;

[0035] 3) Extrude the liquid slurry obtained in step 2 by quantitative extrusion with a screw pump;

[0036] 4) Using the XYZ motion device, according to the three-dimensional geometric model of the bone defect obtained from the CT scan, the internal pore structure parameters of the geometric model were designed through computer programs: hexagonal honeycomb pores, the length of the hole side is 1mm, and the porosity is 80%. The trajectory of the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com