Photocuring biological ceramic composite material for 3D printing, and applications thereof, and printing system

A composite material and bioceramic technology, applied in the field of materials, can solve the problems of difficulty in using the product alone, large sintering shrinkage, and small contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

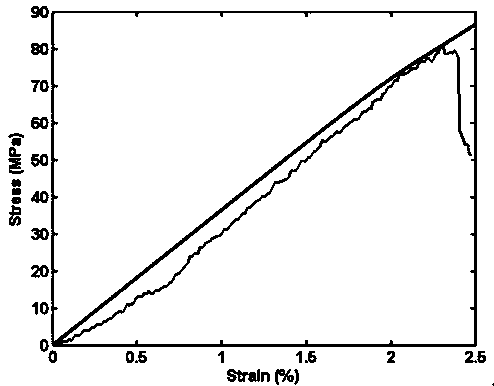

Image

Examples

Embodiment 1

[0061] A light-cured bioceramic composite material for 3D printing, the raw material components and weight ratio of the material are: 10 parts of modified nano-tricalcium phosphate, 55 parts of modified nano-hydroxyapatite, bone morphogenetic 3 parts of protein (BMP), 40 parts of material support, 1 part of dispersant, 3 parts of nano zirconium dioxide, 2 parts of water-soluble rheology additive, 120 parts of deionized water.

[0062] The dispersant is ammonium polyacrylate; the water-soluble rheological additive is xanthan gum; the material support is selected from silk fibroin; the modified nano tricalcium phosphate and the modified nano hydroxyapatite The particle size of stone is less than 50 nanometers.

[0063] The modified nano tricalcium phosphate and the modified nano hydroxyapatite are modified with a modifier, and the raw material components and weight ratio of the modifier are as follows: 30 parts of photocurable resin, 30 parts of photosensitive trigger 3 parts o...

Embodiment 2

[0066] A light-cured bioceramic composite material for 3D printing. The raw material components and weight ratio of the material are: 15 parts of modified nano-tricalcium phosphate, 70 parts of modified nano-hydroxyapatite, bone morphogenetic 8 parts of protein (BMP), 50 parts of material support, 2 parts of dispersant, 5 parts of nano zirconium dioxide, 3 parts of water-soluble rheology additive, 150 parts of deionized water.

[0067] The dispersant is stearic acid; the water-soluble rheology additive is polyvinyl alcohol; the material support is selected from polylactic acid; the modified nano tricalcium phosphate and the modified nano hydroxyapatite The particle size is less than 50 nm.

[0068] The modified nano tricalcium phosphate and the modified nano hydroxyapatite are modified with a modifier, and the raw material components and weight ratio of the modifier are as follows: 40 parts of photocurable resin, 40 parts of photosensitive trigger 6 parts of agent, 70 parts o...

Embodiment 3

[0071] A light-cured bioceramic composite material for 3D printing, the raw material components and weight ratio of the material are: 12 parts of modified nano-tricalcium phosphate, 60 parts of modified nano-hydroxyapatite, bone morphogenetic 5 parts of protein (BMP), 45 parts of material support, 2 parts of dispersant, 4 parts of nano zirconium dioxide, 3 parts of water-soluble rheology additive, 130 parts of deionized water.

[0072] The dispersant is sodium polyacrylate; the water-soluble rheological additive is agarose; the material support is selected from a mixture of silk fibroin and polylactic acid; the modified nano tricalcium phosphate and the modified The particle size of nano-hydroxyapatite is less than 50 nanometers. The modified nano tricalcium phosphate and the modified nano hydroxyapatite are modified with modifiers, and the raw material components and parts by weight ratio of the modifiers are: 35 parts of photocurable resin, 35 parts of photosensitive trigger...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com