Bi-component rubber-mixing machine and closed-loop control method for rubber mixing thereof

A glue mixing machine and two-component technology, applied in the direction of mixers, chemical instruments and methods, fluid mixers, etc., can solve problems such as cumbersome operations, polluting the environment, and imbalance of glue and curing agent ratio, achieving simple operation, Eliminate pollution and meet the effect of proportioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

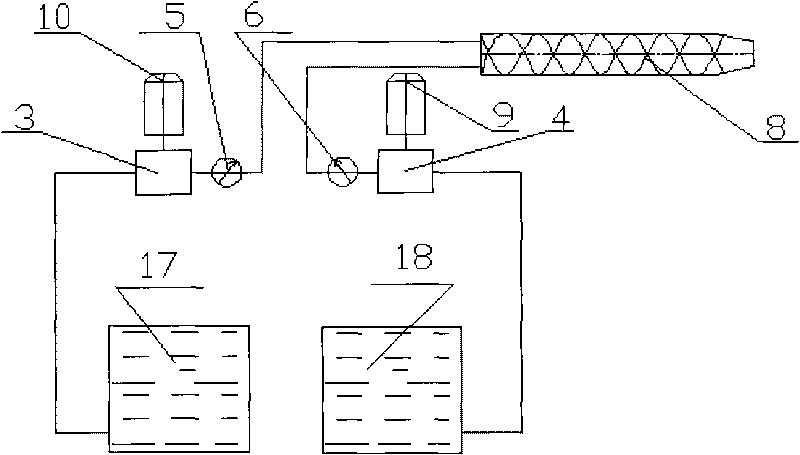

[0035] Such as figure 1 As shown, the rubber mixing machine of the present invention is provided with a rubber raw material barrel 17 for packing glue, and a curing agent raw material barrel 18 for adorning curing agent;

[0036] It is connected with the output port at the bottom of the rubber raw material barrel 17 through a connecting pipeline to the input end of the adjustment quantitative delivery pump 3; a frequency modulation motor 10 is installed on the top of the adjustment quantitative delivery pump 3; the output end of the adjustment quantitative delivery pump 3 is connected to the rubber pipeline flowmeter 5 is connected to the input end, and the output end of the pipeline flow meter 5 is connected to the first input port of the static rubber mixing pipe 8 through the pipeline connected thereto.

[0037] The output port at the bottom of the curing agent raw material barrel 18 is connected to the input end of the adjustment quantitative delivery pump 4 through a conn...

Embodiment 2

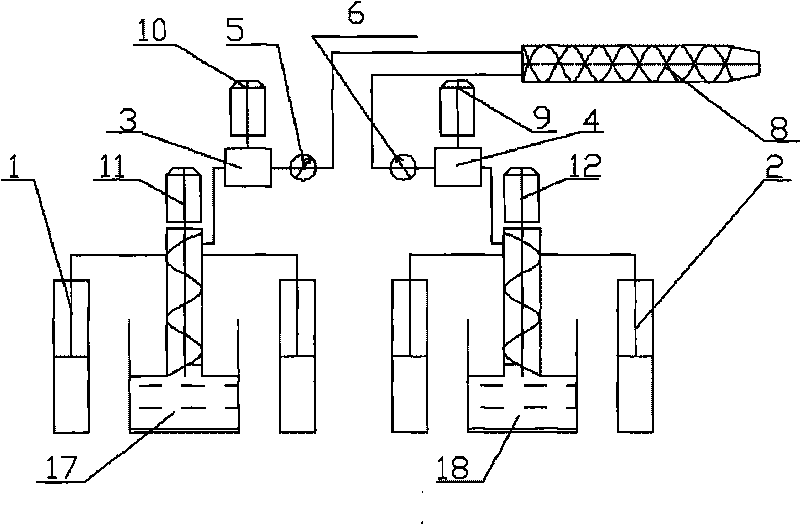

[0048] Such as figure 2 Shown: When the viscosity of the glue used and the viscosity of the curing agent used are both higher than 12000CPS; There are booster pump sets respectively.

[0049] The booster pump set consists of a compression device, a screw pump and a drive motor for the screw pump. Wherein, the screw pump driving motor 11 matched with the rubber raw material barrel 17 is located at the top of the screw pump, and the bottom ends of the screw pump are respectively connected with auxiliary pressure plates; one end of the screw pump with the auxiliary pressure plate is vertically inserted into the rubber raw material barrel 17 , the compression device 1 is a pneumatic cylinder or a hydraulic cylinder; usually there are 2 sets, and 2-4 sets can also be set according to the needs, and they are equiangularly distributed around the rubber raw material barrel 17; the outer ends of the compression rods in each compression device 1 are It is fixedly connected to the upp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com