A mutant strain with acid resistance and high production of ε-polylysine and its application

A technology of Streptomyces and microbial strains, applied in mutant preparation, climate change adaptation, bacteria, etc., can solve problems such as inability to meet industrial production, low yield, etc., achieve good passage stability, high transformation efficiency, and improve positive mutation rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Example 1 Construction and screening of recombinant strains

[0053] First, the integrative plasmid pSET152 was selected, and a recombinant plasmid containing the promoter SF14p (shown in SEQ ID NO. 1) was constructed. Using the Pls gene (SEQ ID NO.2) of strain BNCC 18622 as a template, the Pls gene was amplified by primers pls-F2 (SEQ ID NO.3) and pls-R (SEQ ID NO.4), with Nde I and Xba I Degenerate primers were designed for the restriction site, the Pls gene was double digested, and the integrated plasmid pSET152 (carrying the promoter SF14p) was cut at the same time, the cut Pls gene was connected to the plasmid, and transformed into E. coli competent cells. The positive transformants were verified by DNA sequencing, and the target plasmid was extracted and transformed into E.coli ET12567 / pUZ8002. pUZ8002 is a plasmid containing the tra gene, which encodes the transfer protein Tra, enabling the transformation of plasmid DNA from E. coli to Streptomyces. E.coli ET12...

Embodiment 2

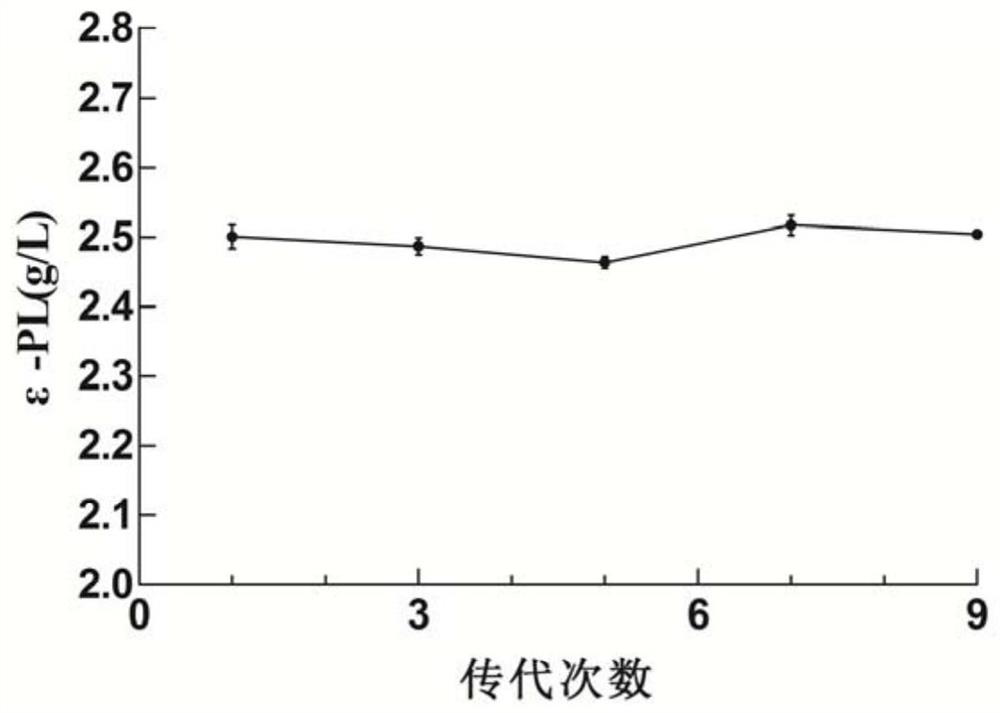

[0064] Embodiment 2 Determination of strain passage stability

[0065] The mutant strain PL-2-AH66 was subcultured, and the 1st, 3rd, 5th, 7th, and 9th generation strains were subjected to shake flask fermentation tests. image 3 For the genetic stability curve, it can be seen that the curve is relatively flat, indicating that the variation range of ε-PL yield is low. It can be seen from Table 2 that the yield of ε-PL in each generation is not much different (less than 0.05g / L), and the yield of the ninth generation is 2.51±0.01g / L, which is basically the same as that of the first generation, which shows its genetic stability. better.

[0066] Table 2 Genetic stability test of PL-2-AH66

[0067]

Embodiment 3

[0068] Example 3 Bacterial two-stage batch fermentation

[0069] The strain PL-2-AH66 obtained in Example 1 was fermented in two-stage batches at pH in a 5L fermentor:

[0070] The seed solution was cultured in a 500mL conical flask with a volume of 100mL, and the culture conditions were 30°C and 200rpm for 24–26h.

[0071] According to the inoculum volume of 8%, it was inoculated into a fermenter containing 2.76L of fermentation medium (initial pH 6.8), the initial rotation speed was 200rpm, and the aeration rate was 1vvm. During the fermentation process, when the pH dropped to 2.8±0.1, the pH value was maintained until the biomass of the bacteria began to decrease, and the pH was adjusted to 3.8±0.1 by adding ammonia water until the fermentation was over. The fermentation process maintains dissolved oxygen (DO) at 15%–25% through changes in rotational speed and aeration. Depend on Figure 4 It can be seen that the whole fermentation process lasted for 54h, and the content...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com