A monorail inspection robot system for belt conveyors in extreme environments

A belt conveyor and inspection robot technology, applied in the direction of conveyor objects, conveyor control devices, manipulators, etc., can solve the problems of complex installation structure of cameras and boxes, affecting work efficiency, and complicated parts, etc., to improve work efficiency. Safety, reduced maintenance and production costs, quick assembly and disassembly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

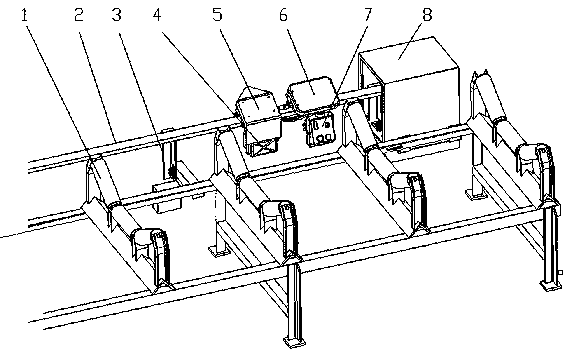

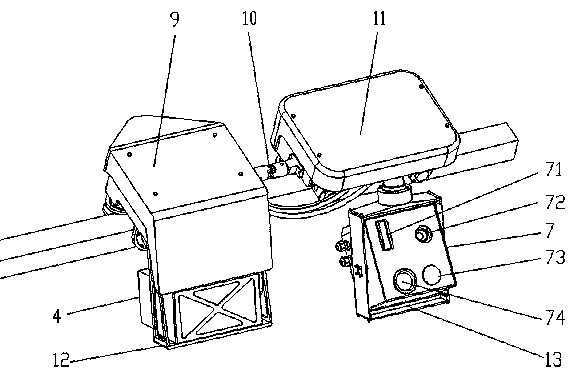

[0039] A monorail inspection robot system for belt conveyors in extreme environments, including an angle steel track 2 composed of mutually perpendicular upper sides 21 and lower sides 22 , a tractor 5 and a detection vehicle 6, the tractor 5 and the probe car 6 are connected by a connection assembly 10, wherein the connection assembly 10 can be a universal joint; the tractor 5 and the probe car 6 are erected on the angle steel track 2 and can walk along the angle steel track 2, and the tractor 5 A power supply device 4 is connected, and the detection device 7 is connected to the detection vehicle 6 , and the power supply device 4 supplies power for the tractor 5 and the detection device 7 at the same time.

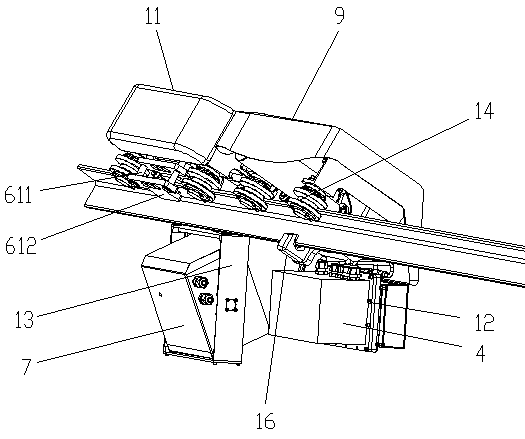

[0040] In this embodiment, the tractor 5 includes 2 suspension wheels 14, 2 traction wheels 15, a first sealed box 9 and a power assembly, the first sealed box 9 is arranged above the angle steel track 2, and the power assembly is arranged at the second In a sealed casing...

Embodiment 2

[0052] A monorail inspection robot system for belt conveyors in extreme environments, including an angle steel track 2 composed of an upper side 21 and a lower side 22 perpendicular to each other, two tractors 5 and a detection vehicle 6, the tractor 5 and the probe vehicle 6 are connected through a connection assembly 10, and two adjacent tractor vehicles 5 are connected through a connection assembly 10, wherein the connection assembly can be a universal joint; the tractor vehicle 5 and the probe vehicle 6 are erected on the angle steel On the track 2 and can walk along the angle steel track 2, the tractor 5 is connected with a power supply device 4, and the detection vehicle 6 is connected with a detection device 7, and the power supply device 4 supplies power for the tractor 5 and the detection device 7 at the same time.

[0053] In this embodiment, the tractor 5 includes 2 suspension wheels 14, 2 traction wheels 15, a first sealed box 9 and a power assembly, the first seale...

Embodiment 3

[0065] A monorail inspection robot system for belt conveyors in extreme environments, including an angle steel track 2 composed of an upper side 21 and a lower side 22 perpendicular to each other, two tractors 5 and two detection vehicles 6, wherein, The tractor 5 and the probe vehicle 6 are arranged alternately, and the tractor 5 and the probe vehicle 6 are connected through a connection assembly 10. In specific operations, the connection assembly can be a universal joint; the tractor 5 and the probe vehicle 6 are erected on On the angle steel track 2 and can walk along the angle steel track 2, the tractor 5 is connected with a power supply device 4, and the detection vehicle 6 is connected with a detection device 7, and the power supply device 4 supplies power for the tractor 5 and the detection device 7 at the same time.

[0066] In specific operations, a detection device 7 can be used as a backup device, and when another detection device 7 breaks down, the detection device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com